Dust remover and bag cage of dust remover

A technology of dust collector and filter bag, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of affecting the dust removal effect of filter bags, deformation of filter bags, reduction of effective filter area of filter bags, etc., and achieves improvement Filtration effect, avoid deformation and loosening, reduce wear and corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be further described below in conjunction with the drawings.

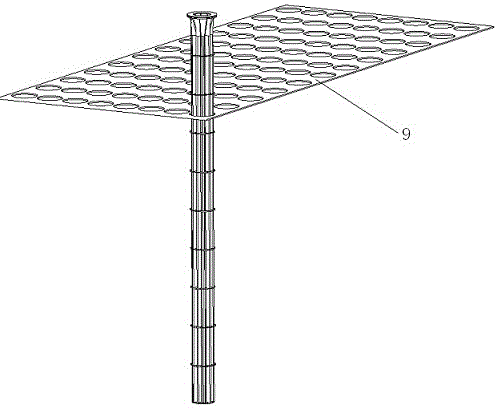

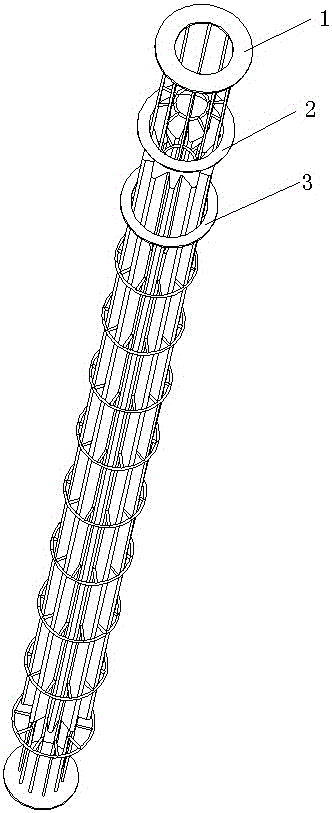

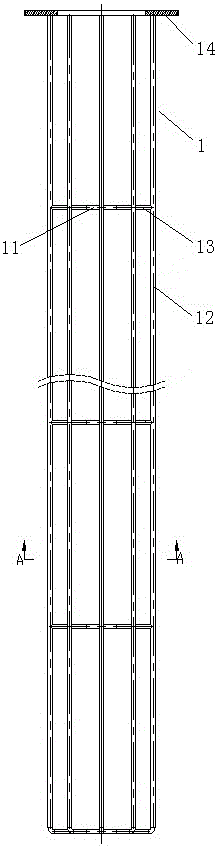

[0024] Specific embodiments of the dust collector of the present invention, such as Figure 1 to 8 As shown, the dust collector includes a flower plate 9, a filter bag 2 installed on the flower plate 9 and a bag cage for supporting the filter bag. The bag cage includes an inner cage 1 and an outer cage 3 that are nested inside and outside, and the filter bag 2 Install between the inner cage 1 and the outer cage 3. The inner cage 1 includes an inner transverse rib ring 11, an inner longitudinal rib 12 located outside the inner transverse rib ring 11, and an inner connecting bar 13 connecting the inner transverse rib ring 11 and the inner longitudinal rib 12, and the inner end of the inner connecting bar 13 is welded to the inner transverse rib ring 11 On the outer circumference of the inner ring, the outer end of the inner connecting strip 13 is welded vertically to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com