Method for detecting integrity of filter element of ultrafiltration membrane

A technology of integrity detection and ultrafiltration membrane, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as substandard water quality and secondary pollution of tap water, and achieve rapid inspection and judgment accuracy. High, improve the effect of inspection operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

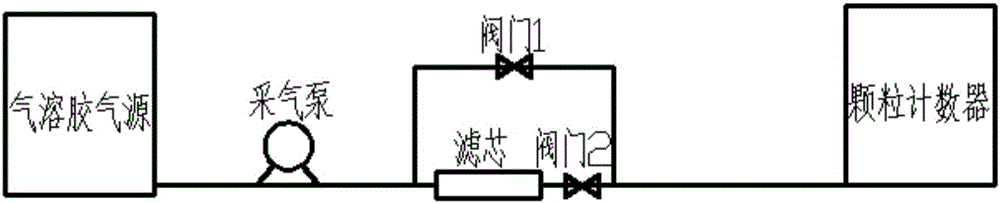

Embodiment 1

[0017] Use the aerosol gas source that artificially generates particulate matter, connect the hollow fiber ultrafiltration membrane filter element, adjust the particle generator in the aerosol gas source, so that the particle size of the generated particles is 0.3-0.5um, and the particle concentration is 40,000-100,000 per liter , close valve 2, open valve 1, open the gas pump and particle counter. The particle counter displays a reading of 108600, that is, the concentration of particles in the air source is 108600 before being filtered by the ultrafiltration membrane filter element; then close valve 1, open valve 2, and the particle counter displays a reading of 28 after the air source is filtered by the ultrafiltration membrane filter element. That is, the concentration of particles in the air source before being filtered by the ultrafiltration membrane filter element is 28; the calculated particle removal rate is 99.97%, and the hollow fiber ultrafiltration membrane filter e...

Embodiment 2

[0020] Use the atmosphere as the gas source, connect the hollow fiber ultrafiltration membrane filter element, close valve 2, open valve 1, turn on the gas sampling pump and particle counter, adjust the gas sampling time of the gas sampling pump, so that the concentration of particulate matter detected by the counter is 35000-55000 per liter , the number of particles detected by the particle counter is 67480, that is, the particle concentration in the air source before being filtered by the ultrafiltration membrane filter element is 67480; then close valve 1, open valve 2, and the particle counter displays after the air source is filtered by the ultrafiltration membrane filter element The reading is 82, and the calculated particle removal rate is 99.87%, which is lower than the integrity limit of 99.9%, so it is judged that the filter element is damaged.

[0021] Replace the hollow fiber ultrafiltration membrane filter element with an aerosol gas source that artificially genera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com