Basic arm rack assembly tooling of dynamic compactor

A basic boom and dynamic compactor technology, applied in auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problems of waste of raw materials, scrapped connectors, low production efficiency, etc., to reduce the dependence of workers' skills and reduce maintenance. cost and the effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

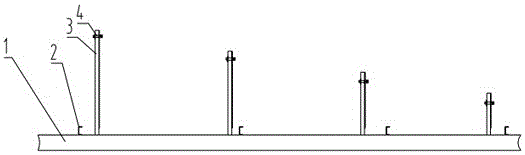

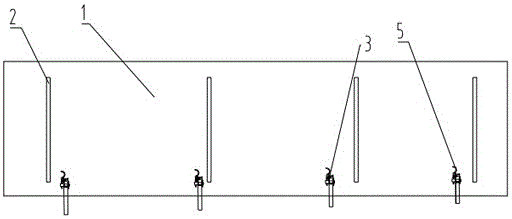

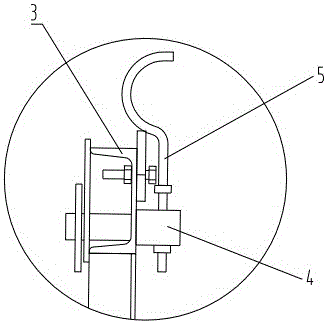

[0016] The present invention discloses a Figure 1-2 The jib assembly tooling for the foundation arm of the dynamic tamping machine shown includes an underframe 1, a row of limit columns 3 installed vertically on one side of the underframe 1, and at least two beams 2 horizontally installed on the upper surface of the underframe 1. The height of the limiting column 3 decreases sequentially from left to right relative to the bottom frame 1. A horizontal pin 4 is installed on the top of the limiting column 3. The axial direction of the pin shaft 4 is the same as the length direction of the bottom frame 1. The pin shaft 4, the supporting hook 5 is fixedly installed; the quantity of the limit column 3 is the same as that of the crossbeam 2, and the crossbeam 2 is made of channel steel, the bottom of which is welded to the chassis 1, and it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com