A processing method for the pump body of a ship water jet propulsion pump

A technology of water jet propulsion and processing method, which is applied in the field of pump body processing and the processing of ship water jet propulsion pump body, to achieve the effects of reducing processes, improving dimensional accuracy, improving processing accuracy and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

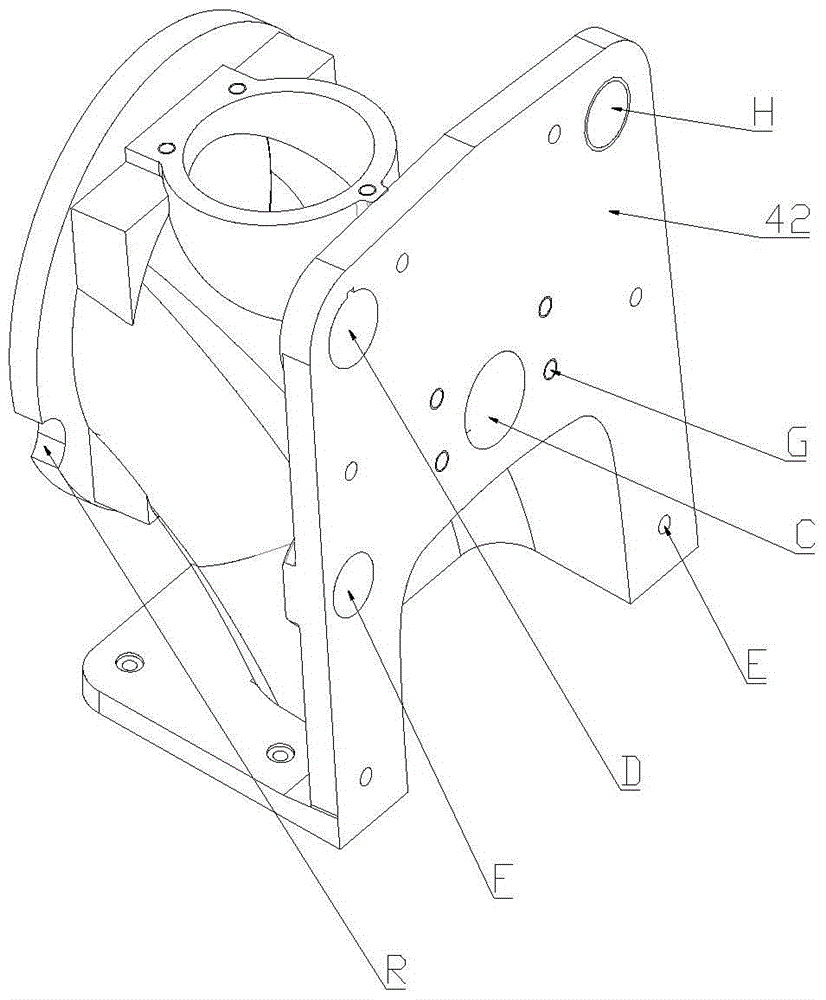

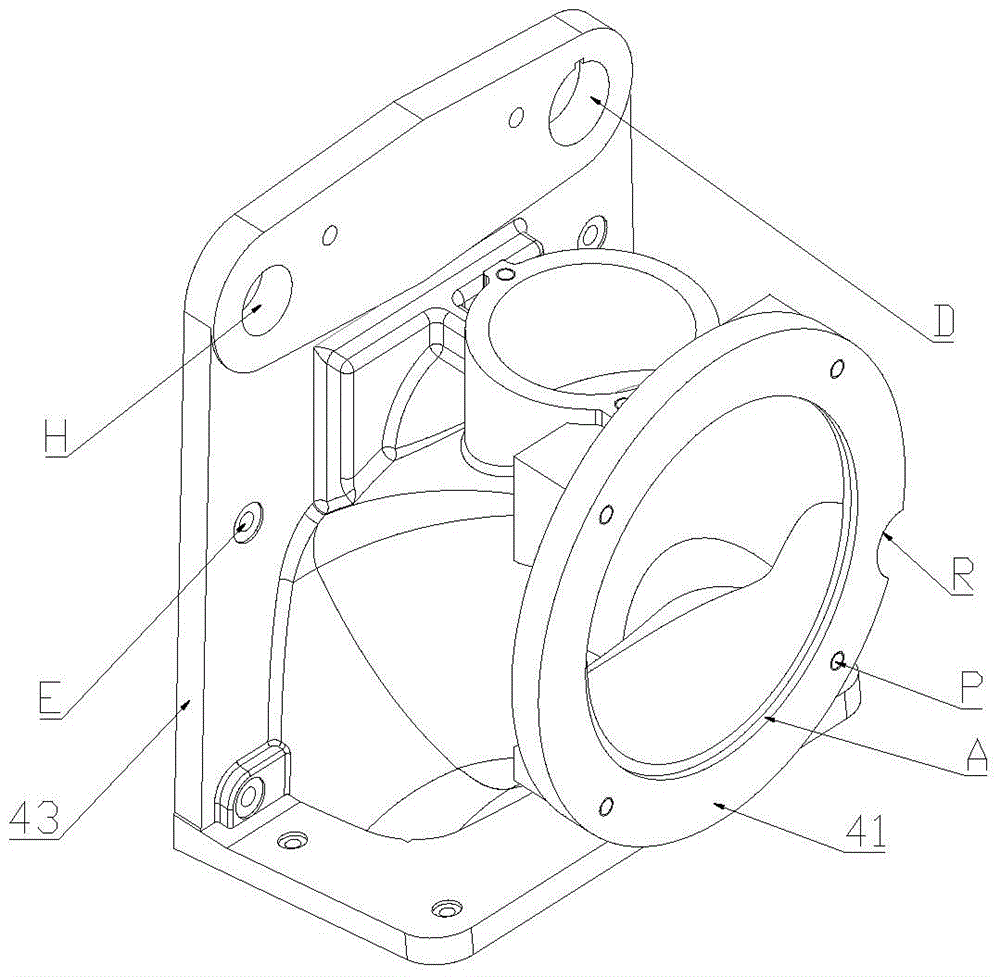

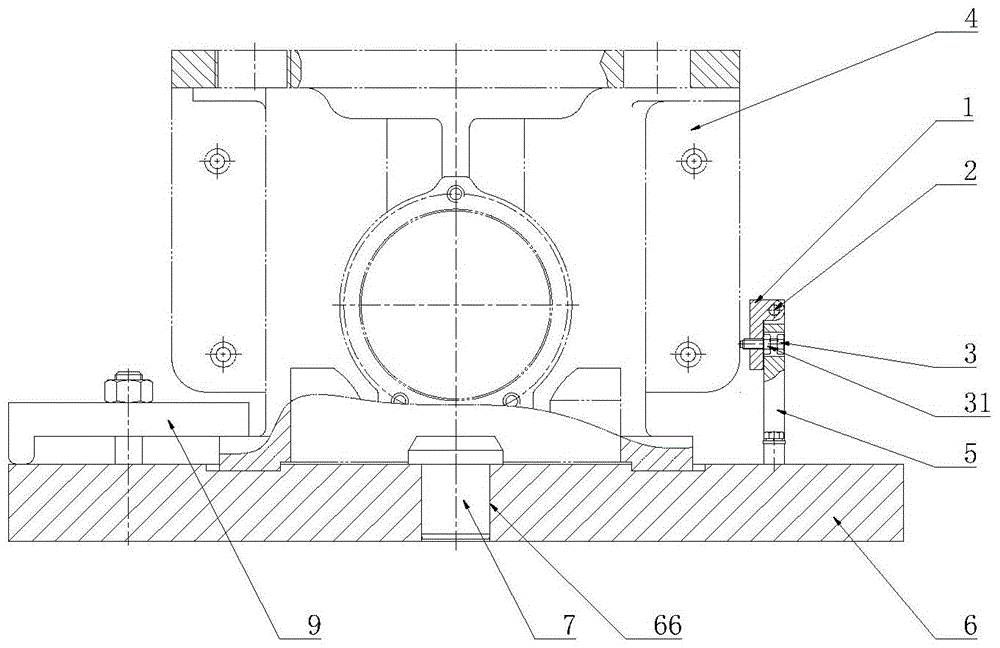

[0033] Such as figure 1 , 2 Shown, is the pump body 4 part diagrams of the water jet propulsion pump to be processed in the present invention, in figure 1 , hole A and hole C are concentric, and the center line is perpendicular to surface 42; figure 2 Among them, hole A is the large spindle hole, hole C is the small spindle hole, hole D is the positioning installation hole for the control cylinder, H is the threaded hole for the control rod bearing in the installation direction, F is the hole for the cooling water pipe of the diesel engine, and E is the installation of the pump body. hole, G is the threaded hole for installing the spindle bearing seat, in image 3 Among them, P is the connection hole, and it is connected with figure 2 The middle G hole maintains the relative position, the center of the R arc and figure 2 Middle F holes remain concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com