Machine for synchronously winding condenser pipe and attaching aluminum foil tape to uniform refrigeration refrigerator

A technology of aluminum foil tape and condenser tube, which is applied in the direction of adhesive, film/sheet adhesive, packaging, etc., can solve the problems of uneven refrigeration, easy drying of food, small space, etc., and achieves easy modification, high degree of automation, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

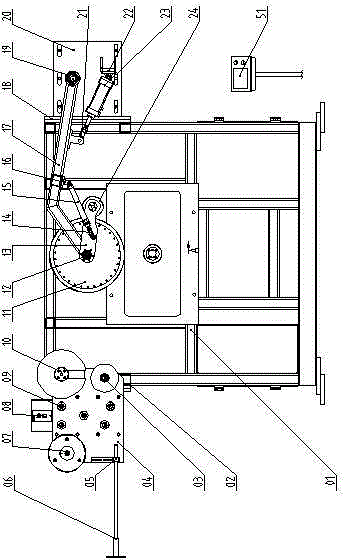

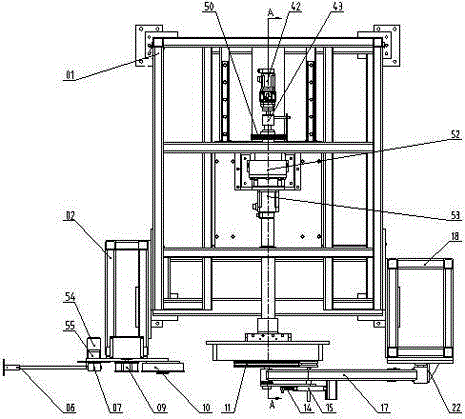

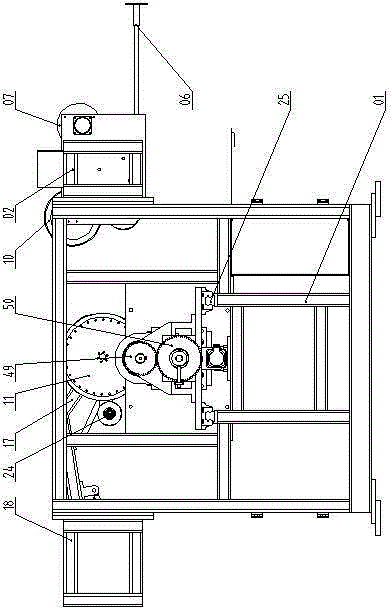

[0020] The present invention will be described in detail below with reference to the drawings and specific embodiments

[0021] first part:

[0022] A synchronous winding and attaching aluminum foil tape machine for the condenser tube of a uniform cooling refrigerator, which includes a frame, a pressure arm adjustment mechanism, an aluminum foil tape automatic attaching and receiving device, a servo drive and a synchronous winding mechanism, a tube winding mold, and a man-machine interface. In part, the aluminum foil tape automatically attaches the paper delivery device and the pressure arm adjustment mechanism are located on the left and right sides of the frame. The servo drive and the synchronous winding mechanism are fixed and the middle of the frame. The tube winding mold and the flange of the synchronous winding mechanism are aligned. Connect, the man-machine interface is a single operating platform.

[0023] the second part:

[0024] After the whole machine is powered on, it i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap