Raw material carrying trolley capable of automatically traveling

A technology for handling trolleys and automatic walking, applied in the direction of lifting devices, etc., can solve the problems of low efficiency, high labor intensity, and the trolley cannot be stopped stably.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

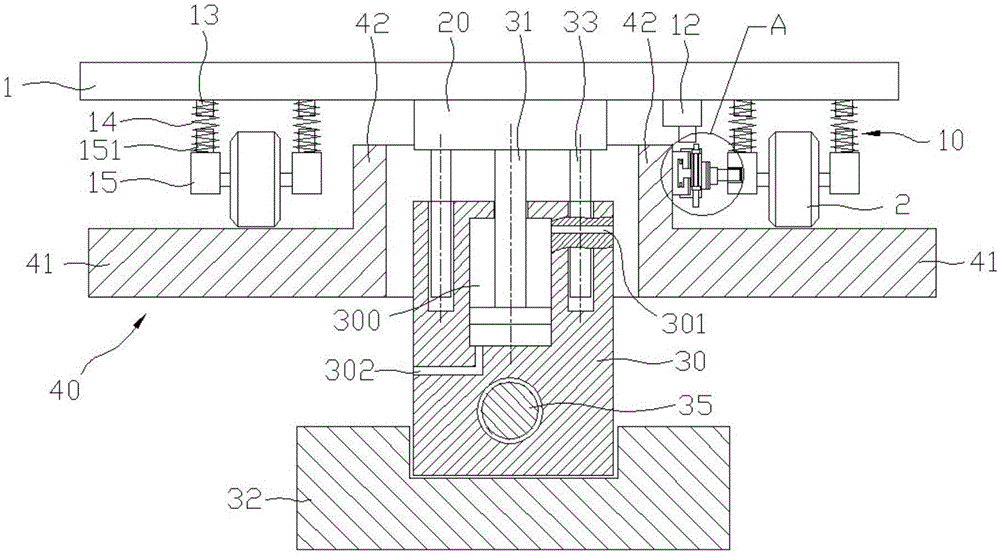

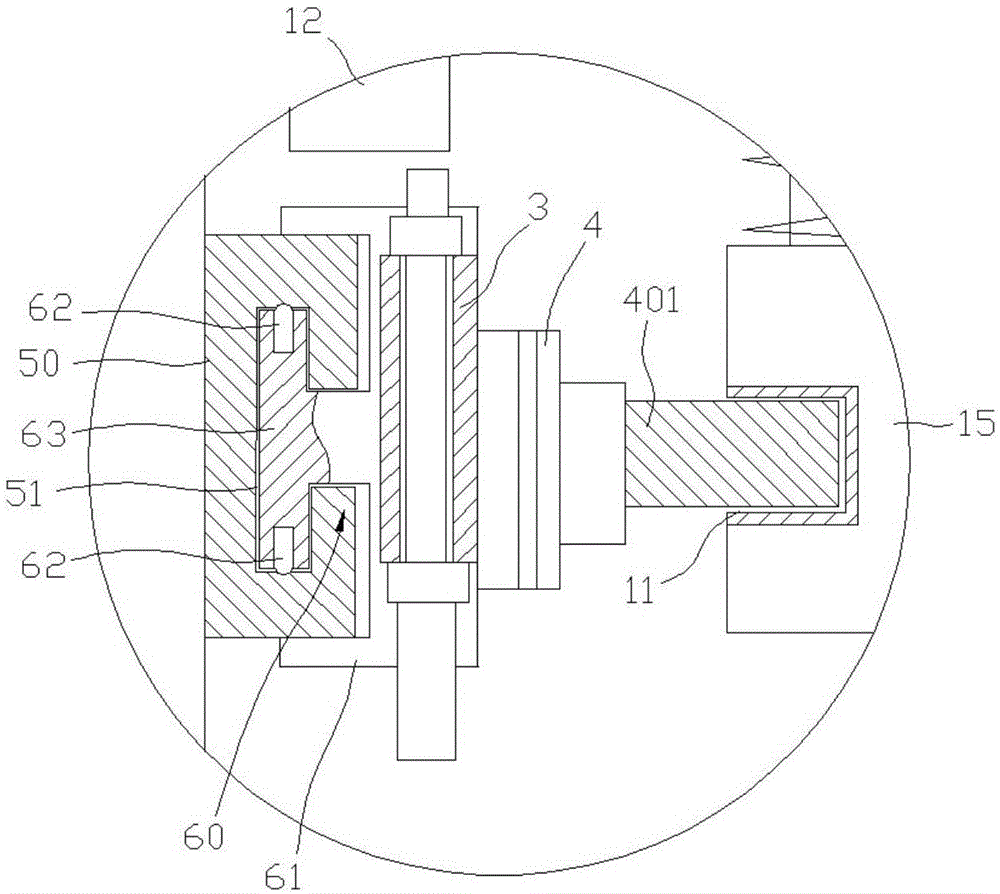

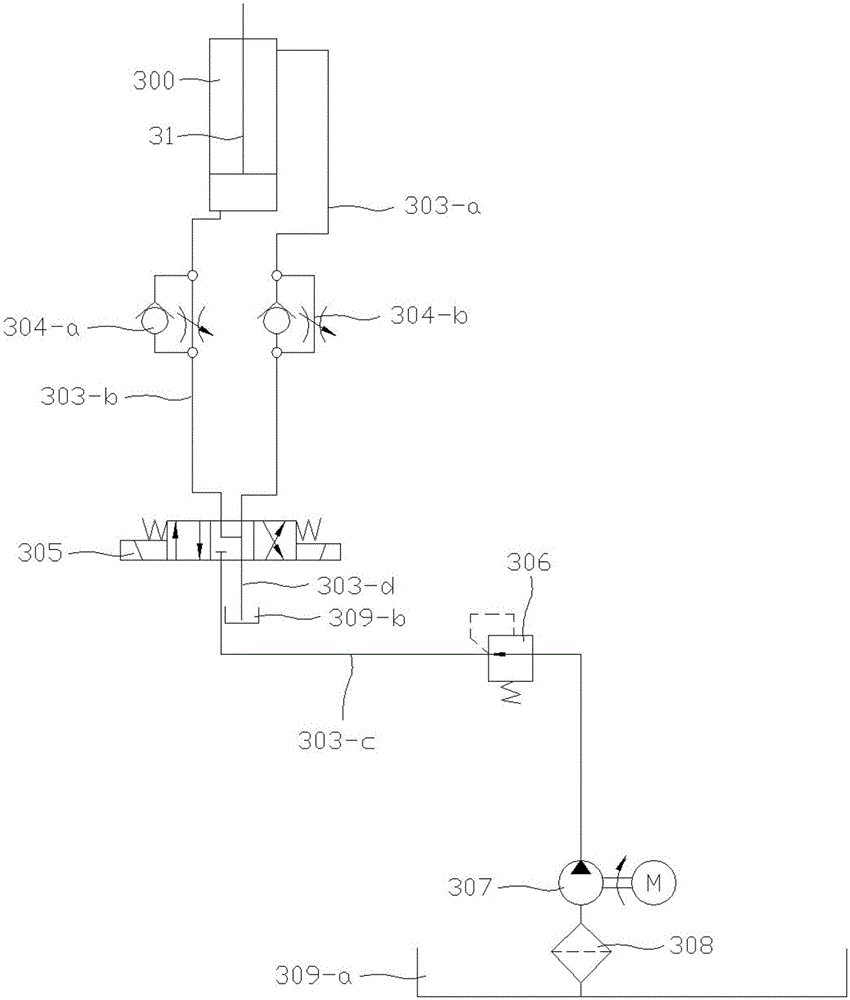

[0033] Such as figure 1 , a raw material handling trolley capable of walking automatically, comprising a material plate 1, a mobile connecting block 20 is fixed in the middle of the bottom surface of the material plate 1, a walking block 30 is arranged below the moving connecting block, and a hydraulic cavity 300 is provided inside the walking block, The top of the hydraulic chamber is provided with a first oil outlet 301, and the bottom of the hydraulic chamber is provided with a second oil outlet 302. The first oil outlet and the second oil outlet are connected to the hydraulic system, and a piston rod 31 is movably inserted in the hydraulic chamber. The rod is vertically arranged, and the top of the piston rod protrudes from the walking block, and the top of the piston rod is fixedly connected with the bottom surface of the mobile connecting block. The guide hole fits; the walking block is slidably fitted on the sliding base 32, and the walking block is provided with a thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com