Die positioning and adjusting structure for double-bent glass forming machine

A positioning adjustment and molding machine technology, applied in glass molding, glass reshaping, glass production, etc., can solve the problems of inability to adjust height, weak applicability, and heavy mold frame, so as to improve production efficiency, ensure quality, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

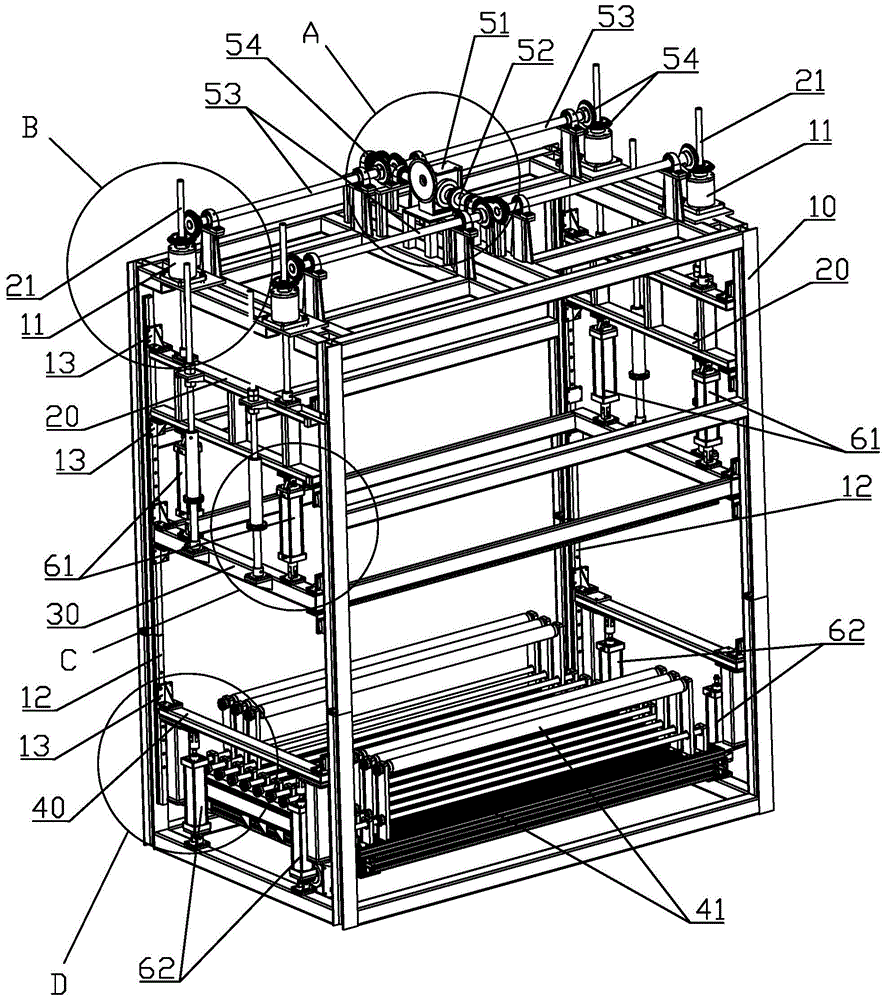

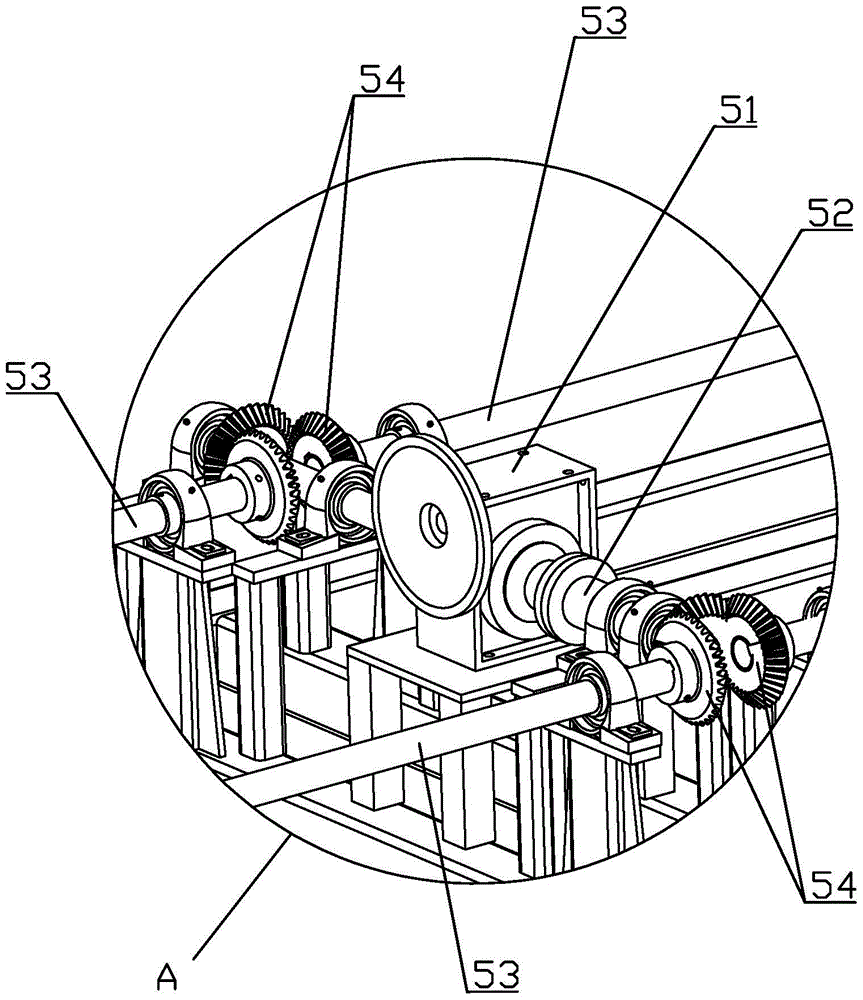

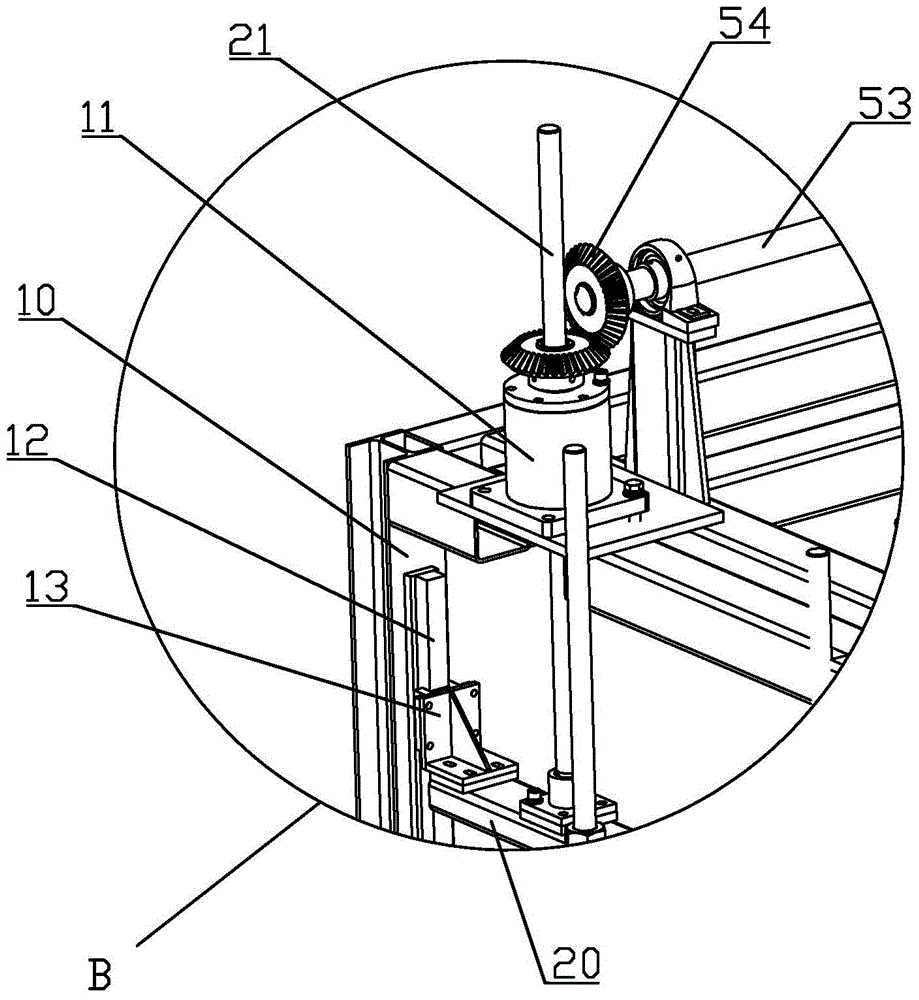

[0021] refer to Figure 1 to Figure 5 , a mold positioning adjustment structure for a double-curved glass forming machine, comprising a frame 10 and two movable beams 20 respectively arranged on the left and right sides of the frame 10, each movable beam 20 is respectively fixed with at least one longitudinal screw rod 21, The frame 10 is provided with a number of sleeves 11 matched with the screw rods 21. These sleeves 11 are driven by a driving device through a transmission mechanism to rotate synchronously, thereby pushing the two movable beams 20 to move up and down synchronously; The formwork 30 is slidably arranged on the frame 10 and is located below the movable beam 20. The left and right sides of the upper formwork 30 are respectively connected with the movable beam 20 through at least one longitudinal first cylinder 61. The first cylinder 61 is used to push the upper The formwork 30 makes it move up and down relative to the movable beam 20; the lower formwork 40 is s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap