Synthesized counterweight filler

A technology of counterweight and weight ratio, applied in the field of synthetic counterweight, can solve the problems of high labor cost and material cost, unfavorable environmental protection in welding operation, and multi-steel, etc., to save the amount of steel used, reduce the painting process, The effect of reducing labor and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

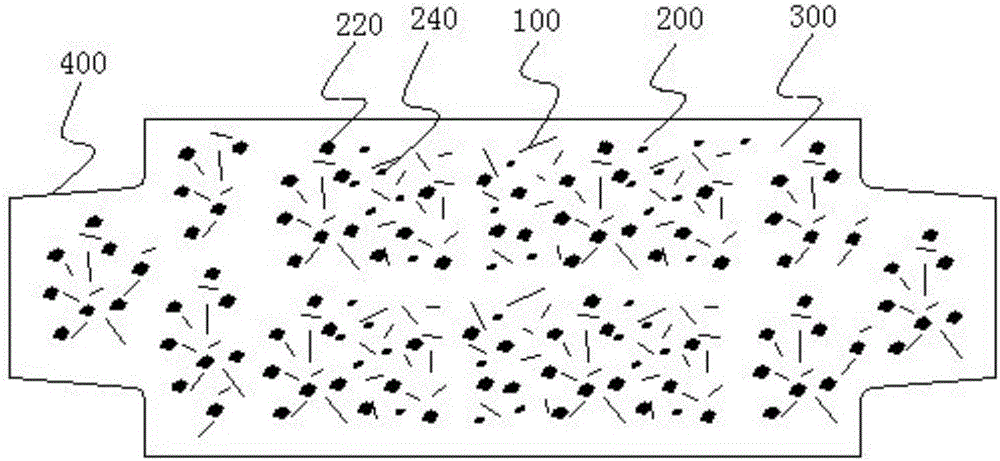

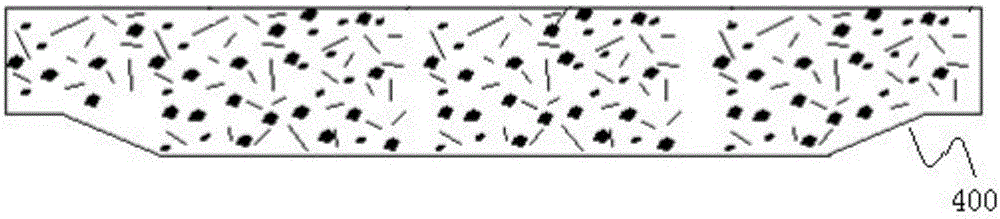

[0021] Embodiment 1, the synthetic counterweight of the present invention includes the metal fiber 100 with a weight ratio of 6.5%, the ore and metal slag 200 with a weight ratio of 70%, and the cement 300 with a weight ratio of is 23.5%, and the water-cement ratio is 0.4.

Embodiment 2

[0022] Embodiment 2, the synthetic counterweight of the present invention includes the metal fiber 100 with a weight ratio of 1.5%, the ore and metal slag 200 with a weight ratio of 60%, and the cement 300 with a weight ratio of is 38.5%, and the water-cement ratio is 0.5.

Embodiment 3

[0023] Embodiment 3, the synthetic counterweight of the present invention includes the metal fiber 100 with a weight ratio of 10%, the ore and metal slag 200 with a weight ratio of 69%, and the cement 300 with a weight ratio of is 24.5%, and the water-cement ratio is 0.45.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com