Outer decorating layer formwork for conical columns of comprehensive gym and construction method of outer decorating layer formwork

A construction method and decorative layer technology, which are applied to the outer decorative layer formwork of a conical column of a comprehensive gymnasium and its construction field, can solve the problems of high engineering cost, waste of materials, occupation, etc., and achieve satisfactory molding effect, easy assembly and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

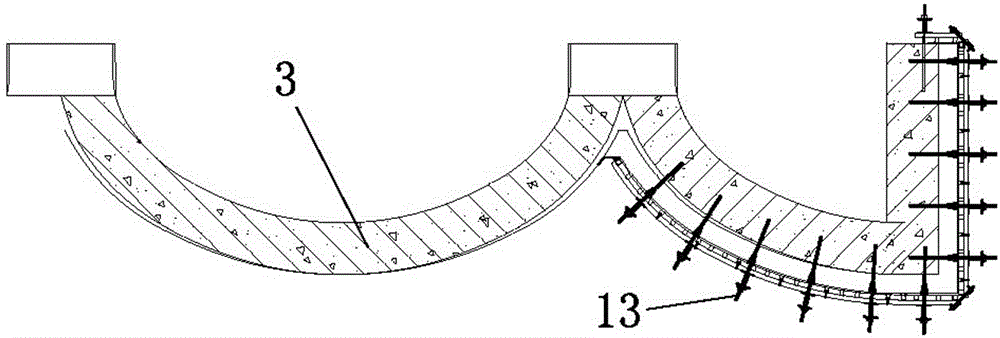

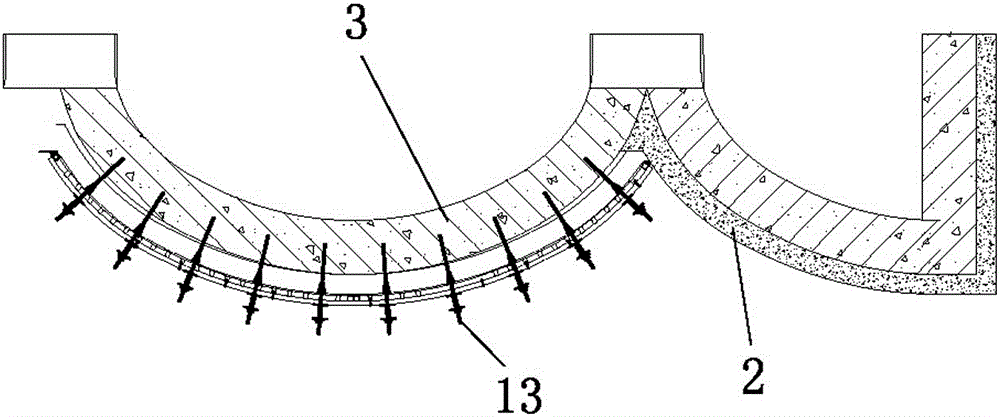

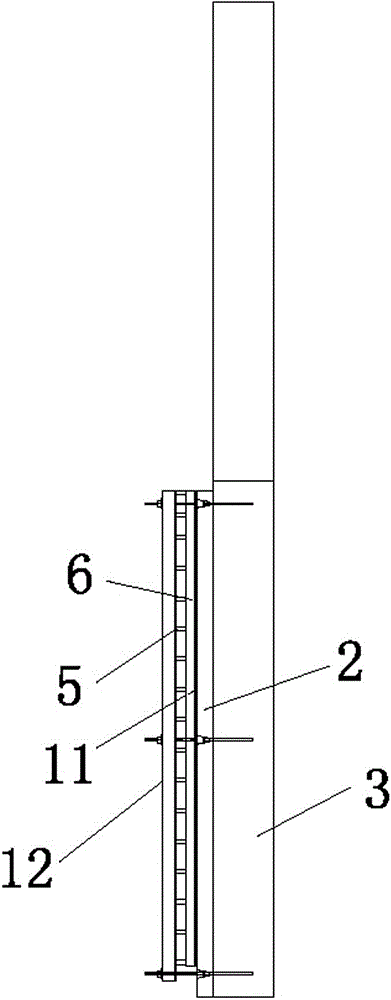

[0030] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

[0031] Such as Figure 1-Figure 2 As shown: the external decorative layer template of the tapered column of the comprehensive gymnasium, the external decorative layer template is located outside the external decorative layer 2, the external decorative layer template includes a cylinder template and a cone template, and the circular top surface of the cylinder template is a cone The bottom surface of the body formwork; the external decorative layer formwork includes: double-layer backboard 11, main keel channel steel back flute 12, secondary keel channel steel 14, several-character beam back flute 6, square steel pipe 5 and pull screw 13, double-layer back The side of the plate 11 facing the decorative layer is lined with plywood, and one end of the pull screw 13 is anchored on the conical concrete column 3, and the main keel channel steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com