A Frictionless Fluid Damping Vibration Isolator

A technology of fluid damping and vibration isolator, which is applied in the direction of liquid shock absorber, spring/shock absorber, vibration suppression adjustment, etc. It can solve the problems of large damper size, poor vibration isolation performance, and reduced size of vibration isolator. , to achieve the effect of enhanced damping capacity, wide application range and avoiding friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

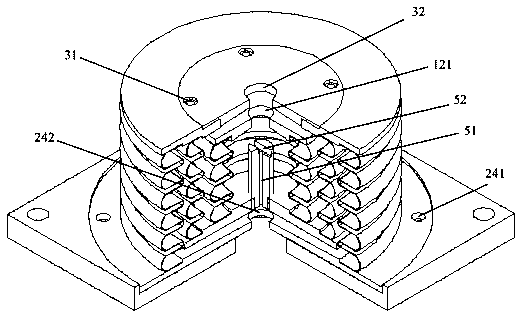

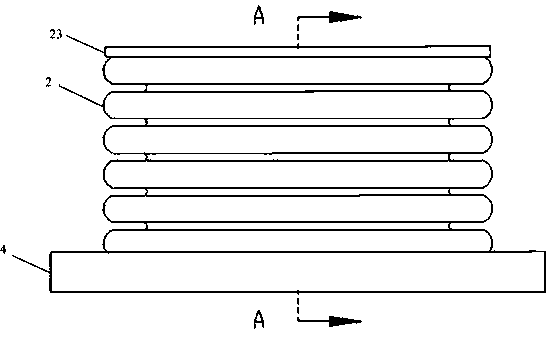

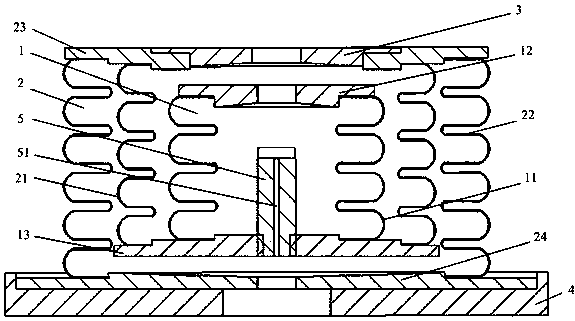

[0049] to combine Figure 1-Figure 9 , this embodiment describes in detail the frictionless fluid damping vibration isolator of the present invention, the sectional view of which is cut off by a quarter is as follows figure 1 shown, as figure 2 Shown is the front view of the frictionless fluid damping vibration isolator of the present invention, as image 3 shown along figure 2A cross-sectional view of the A-A direction, which includes: an inner cavity body 1, an outer cavity body 2, an upper connecting piece 3, a lower connecting piece 4 and a connecting rod 5. The inner cavity body 1 includes: an inner cavity bellows 11, an upper end cover 12 and a lower end cover 13, the upper end of the inner cavity bellows 11 is connected with the upper end cover 12, and the lower end is connected with the inner ring of the lower end cover 13; the outer cavity body 2 includes: The bellows 21 inside the chamber, the bellows 22 outside the outer chamber, the upper flange 23 and the low...

Embodiment 2

[0061] In this embodiment, on the basis of Embodiment 1, a buffer spring 6 is added between the upper end cover 12 and the upper flange 23, which is fixedly connected with the upper end cover 12 and the upper flange 23, and its structural diagram is as follows Figure 10 As shown, the vibration isolator becomes a three-parameter system.

[0062] In different embodiments, the buffer spring can also be replaced by other forms of buffer devices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com