Lifting type smoke exhaust

A range hood and lift-type technology, applied in the field of household appliances and kitchenware, can solve the problems of loud operation noise, inconvenient cleaning, environmental pollution, etc., and achieve the effects of increasing suction, facilitating cleaning, and avoiding the escape of oil fume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

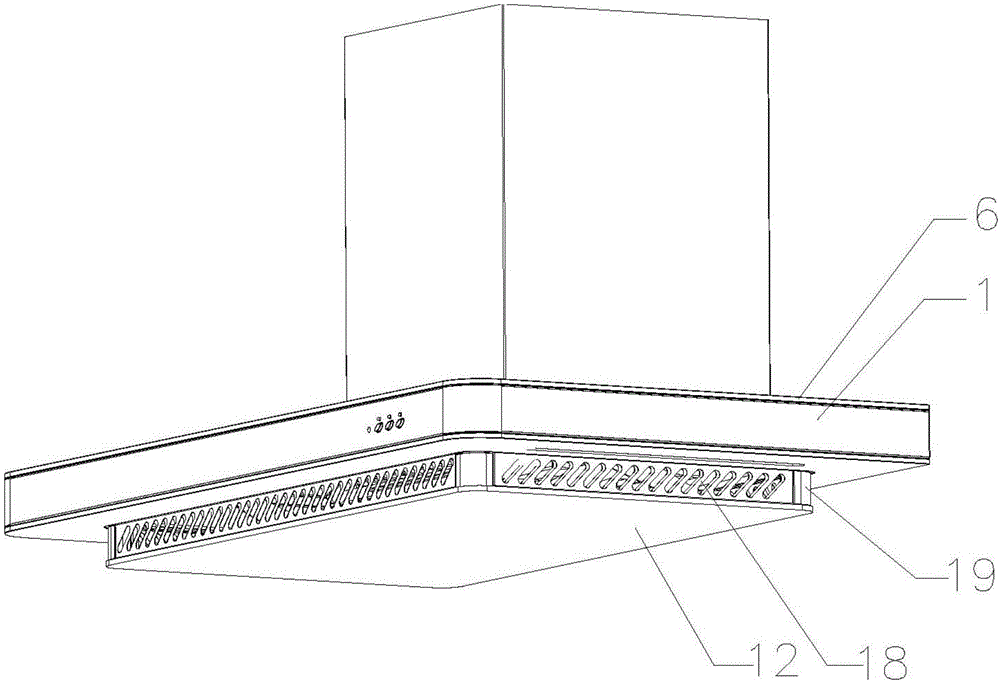

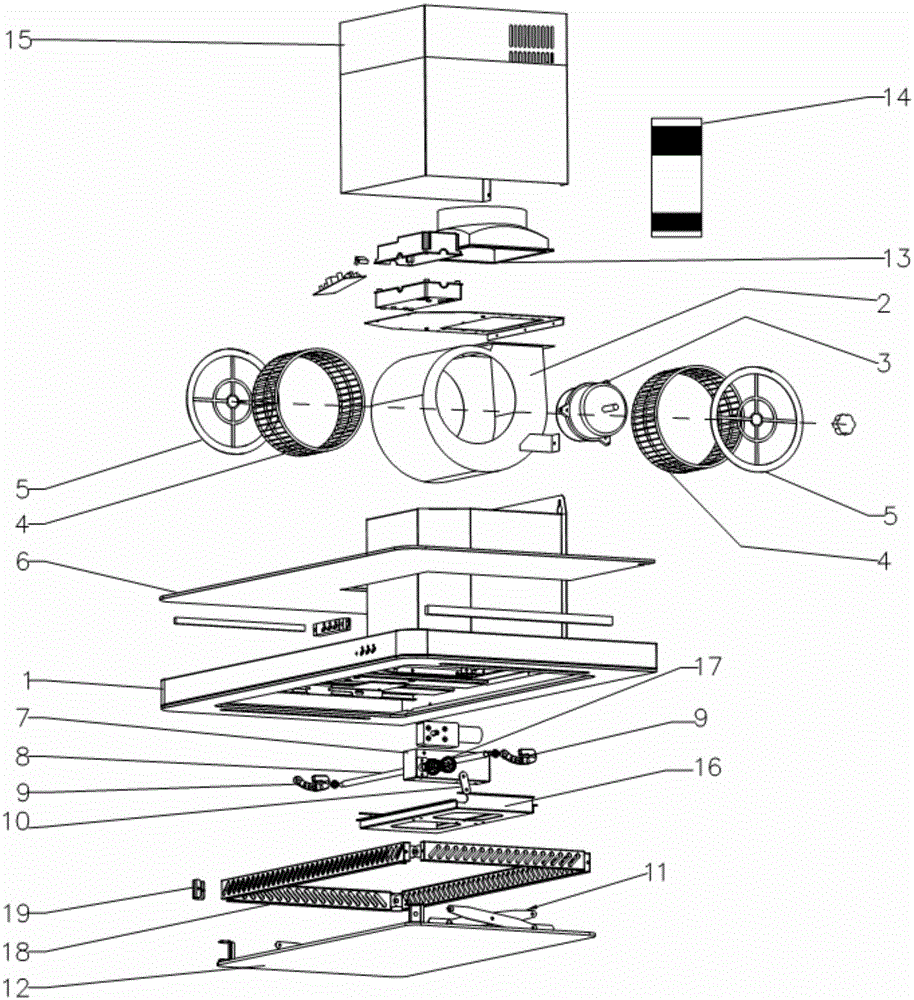

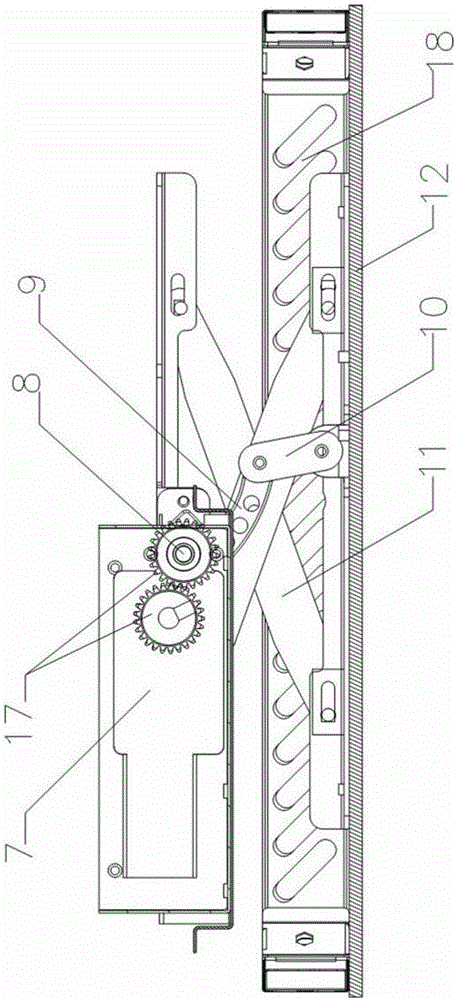

[0020] Please refer to the attached figure 1 to attach Figure 4 As shown, the present invention is a lifting range hood, which consists of a box body 1, a volute 2, a motor 3, a wind wheel 4, an air inlet ring 5, an upper glass plate 6, a motor 7, a connecting rod 8, and a driving rod 9 , fork 10, X-type elevating rod 11 and several parts such as elevating glass plate 12 are assembled, and other parts irrelevant to the innovation point of this creation are no longer repeated here.

[0021] Wherein, the volute 2 is accommodated in the upper part of the box body 1, and a motor 3, a wind wheel 4 and an air inlet ring 5 are arranged therein. The top of the volute 2 is also provided with an air outlet seat 13 . An air outlet pipe 14 is connected to the air outlet seat 13, and the air outlet pipe 14 can discharge oil fumes to the outside. The air outlet pipe 14 is covered with a decorative cover 15 .

[0022] The motor 3 is installed in the volute 2 . The wind wheel 4 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com