Simple centrifugal dryer

A centrifugal dryer, a simple technology, applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., can solve the problems of material crushing, contamination, material transfer, etc., and achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

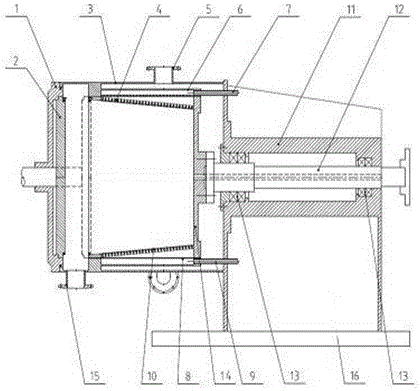

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] Simple centrifugal dryer, including machine cover 1, drum front cover 2, casing 3, drum body 4, exhaust port 5, blowback cavity 6, upper air intake pipe 7, drying chamber 8, lower air intake pipe 9, Filter screen 10, bearing 13 box 11, main shaft 12, bearing 13, drum back cover 14, discharge port 15, base 16, characterized in that the bearing 13 box 11 is arranged on the support, the machine cover 1 and the bearing 13 box 11 An organic casing 3 is arranged between them, an exhaust port 5 is arranged above the outer ring of the casing 3, a discharge port 15 is arranged below the outer ring, and a blowback chamber 6 is arranged above the inner wall of the casing 3, and the blowback chamber 6 is arranged above the inner wall of the casing 3, and the blowback The cavity 6 communicates with the upper air intake pipe 7, and a drying cavity 8 is arranged under the inner wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com