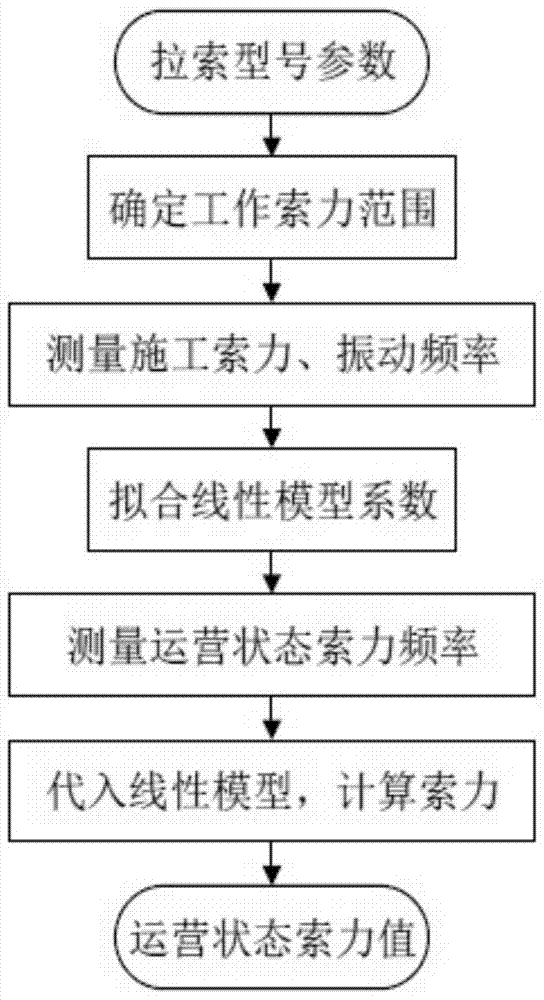

Method for Measuring Cable Force of Vibrating Cable Based on Linear Model

A linear model and measurement method technology, applied in the direction of tension measurement, etc., can solve problems affecting measurement accuracy, different definitions of measurement method parameters, and mixed operation difficulties, so as to reduce model uncertainty and avoid identification problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

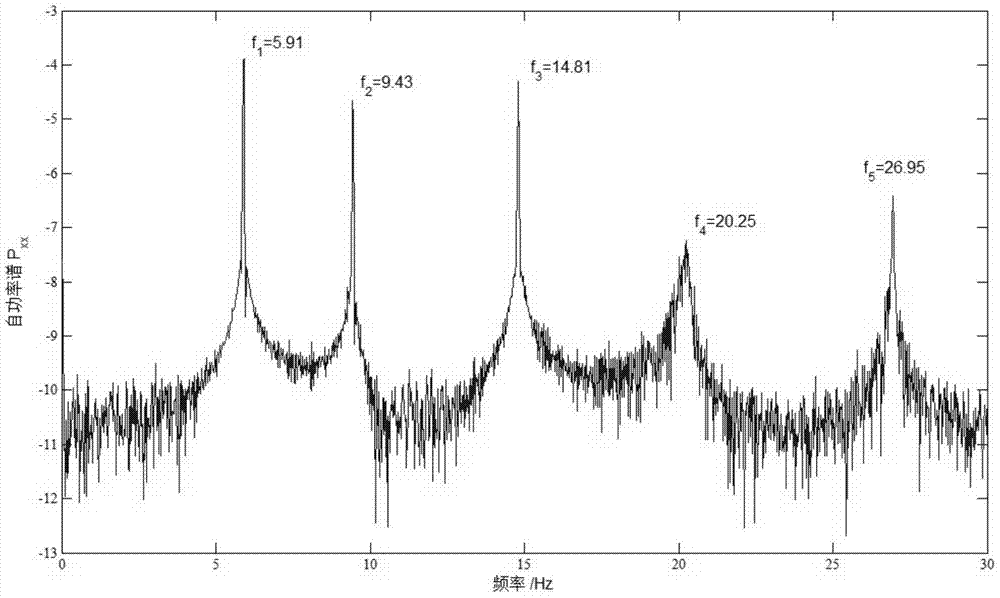

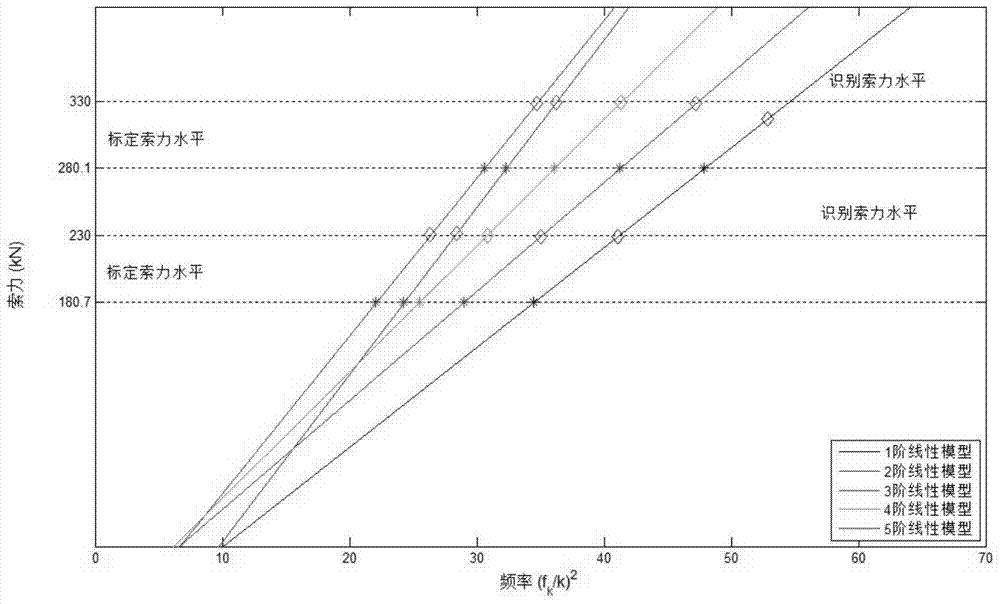

[0058] In the following, the method will be further described in detail by taking a tension test of a cable of model S4 as an example in conjunction with the accompanying drawings.

[0059] The model for the tension test is as Figure 4 , the two ends of the cable are loaded with tension through the numerical control jack. As can be seen from the figure, due to the indirect force transmission of the connecting screw, the boundary conditions (hinged, fixed) of the cable are difficult to visually identify.

[0060] Figure 5 It is a typical cable section, the cable model is S3J, and the cable section includes 3×7+3 steel wires. The cable in this example is S4 type, the cross-section includes 4 bundles of 4×7 steel wires, and the gap and the outside are wrapped by polyethylene (PE). Cable length l=11.57m, linear density m=5.59kg / m, cross-sectional area A=556mm 2 , the limit cable force T lim =1041.60kN, elastic modulus E=2.0×10 5 MPa. The section moment of inertia I is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear density | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com