Data transmission cable for physically-foamed insulation transponder

A data transmission cable, physical foaming technology, applied in the direction of insulated cables, insulated conductors, cables with twisted strands/quad strands, etc., can solve the problems of high cable manufacturing cost and increased tedious manufacturing process, etc. Achieve the effects of reducing the manufacturing process, reducing the relative dielectric constant, and reducing transmission attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0022] It should be noted that the embodiments of the present invention and the features in the embodiments can be combined with each other if there is no conflict.

[0023] Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

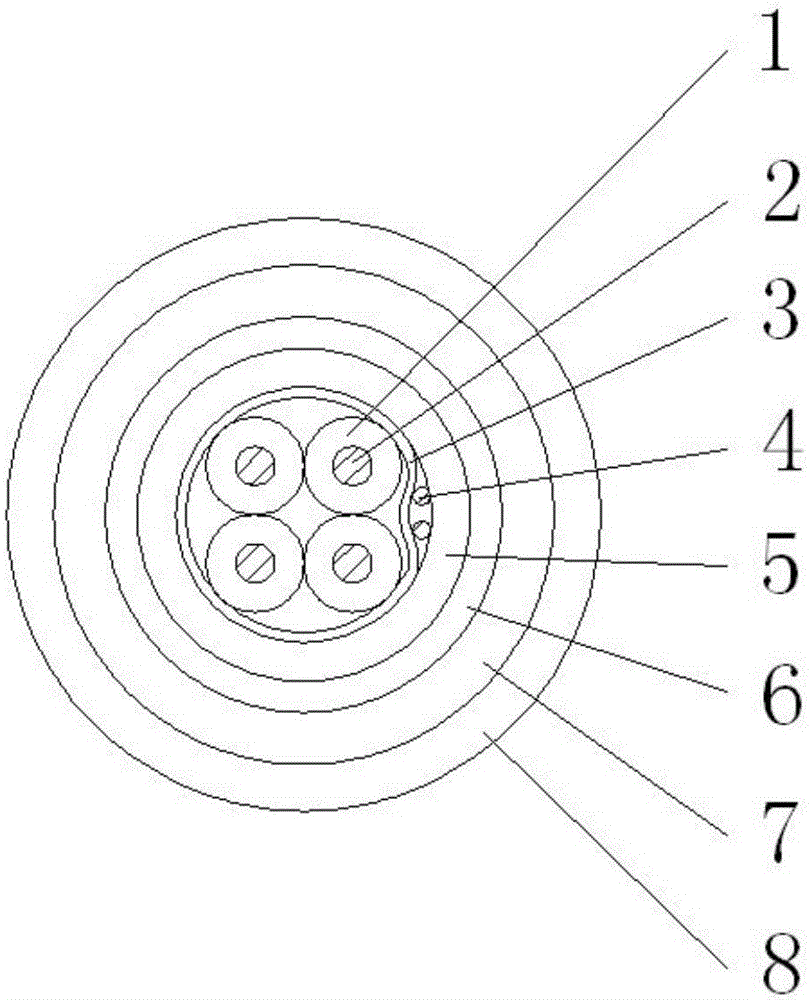

[0024] A physical foam insulated transponder data transmission cable, such as figure 1 As shown, it includes a cable core formed by twisting two or four insulated single wires, as well as an insulating lining 3, a base sheath 5, an inner sheath 6, and a double steel tape armor that are sequentially arranged from the inside to the outside of the cable core Packing layer 7, outer sheath 8; a drain copper wire 4 is provided between the insulating liner 3 and the base sheath 5; the insulated single wire consists of the copper conductor 2 and the skin-foam-skin three outside the copper conductor 2 Layer co-extruded physical foamed polyolefin insulation structure 1.

[0025] It shou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com