Formaldehyde-free bio-based back plate adhesive for mineral wool sound absorption plate and preparation method

A mineral wool sound-absorbing board, bio-based technology, applied in the directions of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the discomfort of people, application limitations, and the lack of moisture-proof and sag-proof backboard adhesives, etc. problem, to achieve the effect of improving moisture-proof performance and moisture-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

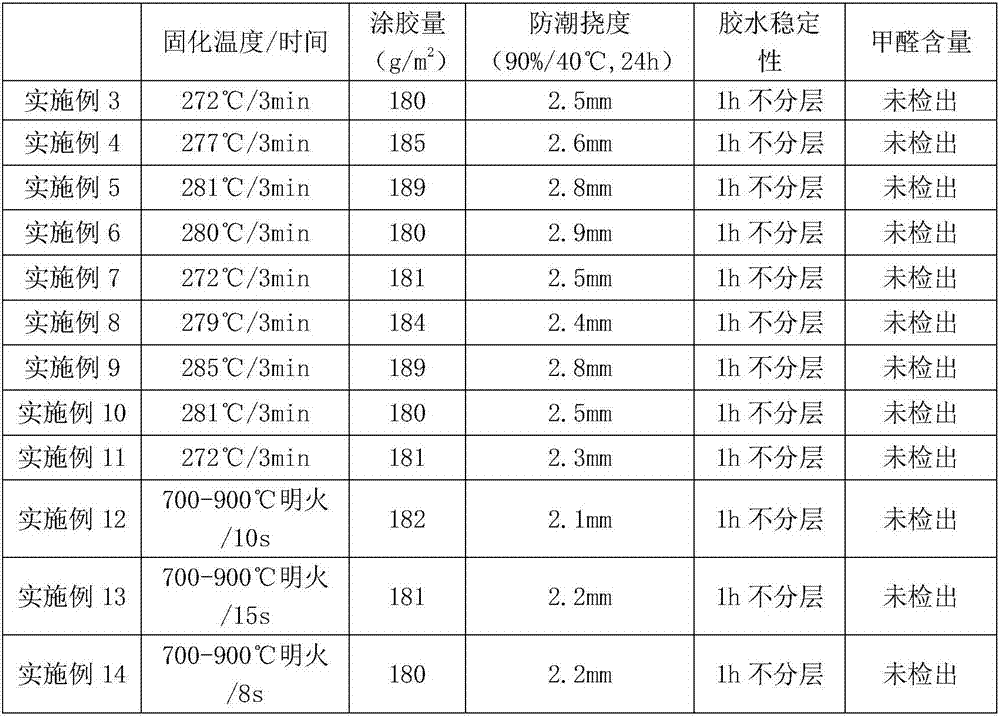

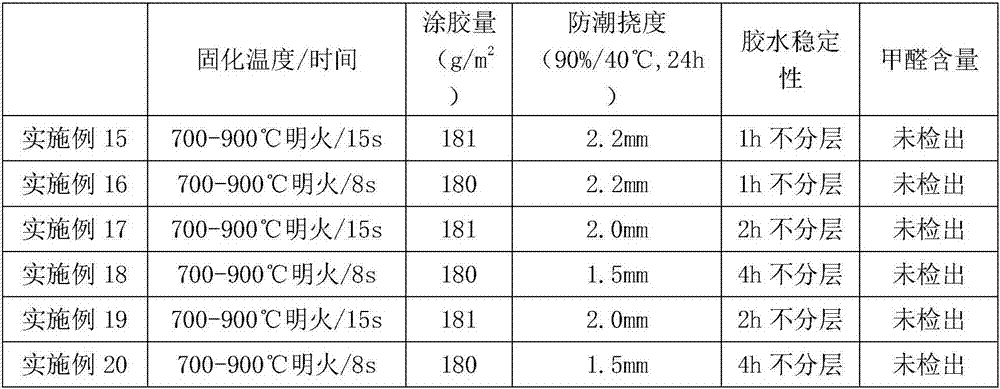

Examples

Embodiment 1

[0017] Embodiment 1 (preparation of modified acrylic resin)

[0018] Formula: 60 parts of water-soluble acrylic resin, 5 parts of casein, 0.5 part of microcrystalline paraffin, 1 part of sodium benzoate, 2 parts of agar, 0.5 part of silane coupling agent, and 5 parts of water.

[0019] According to the above formula, mix water and water-soluble acrylic resin evenly, add casein at 30-35°C, mix in a high-speed mixer, then adjust the pH to 3-5, add sodium benzoate and agar to it, stir well, and then Add silane coupling agent and microcrystalline paraffin, stir and mix evenly.

Embodiment 2

[0020] Embodiment 2 (preparation of modified acrylic resin)

[0021] Formula: 80 parts of water-soluble acrylic resin, 15 parts of casein, 1 part of microcrystalline paraffin, 2 parts of sodium benzoate, 3 parts of agar, 1.5 parts of silane coupling agent, and 10 parts of water.

[0022] According to the above formula, mix water and water-soluble acrylic resin evenly, add casein at 30-35°C, mix in a high-speed mixer, then adjust the pH to 3-5, add sodium benzoate and agar to it, stir well, and then Add silane coupling agent and microcrystalline paraffin, stir and mix evenly.

Embodiment 3

[0023] Embodiment 3 (research on formula of backboard glue)

[0024] Formula: 20 parts of modified water-soluble acrylic resin, 30 parts of biomass raw material, 30 parts of filler, 1 part of potassium tripolyphosphate, and 20 parts of water.

[0025] The modified water-soluble acrylic resin adopts the product obtained in Example 1. The biomass raw material is glucose syrup. The filler adopts glass microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com