Cellular cavity-stage integrated fuel cell electrode and preparation method thereof

A fuel cell electrode, honeycomb technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of increased fuel transmission resistance, reduced battery performance, complicated assembly and sealing, etc., to improve discharge current, simple and compact structure, Easy to assemble and seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

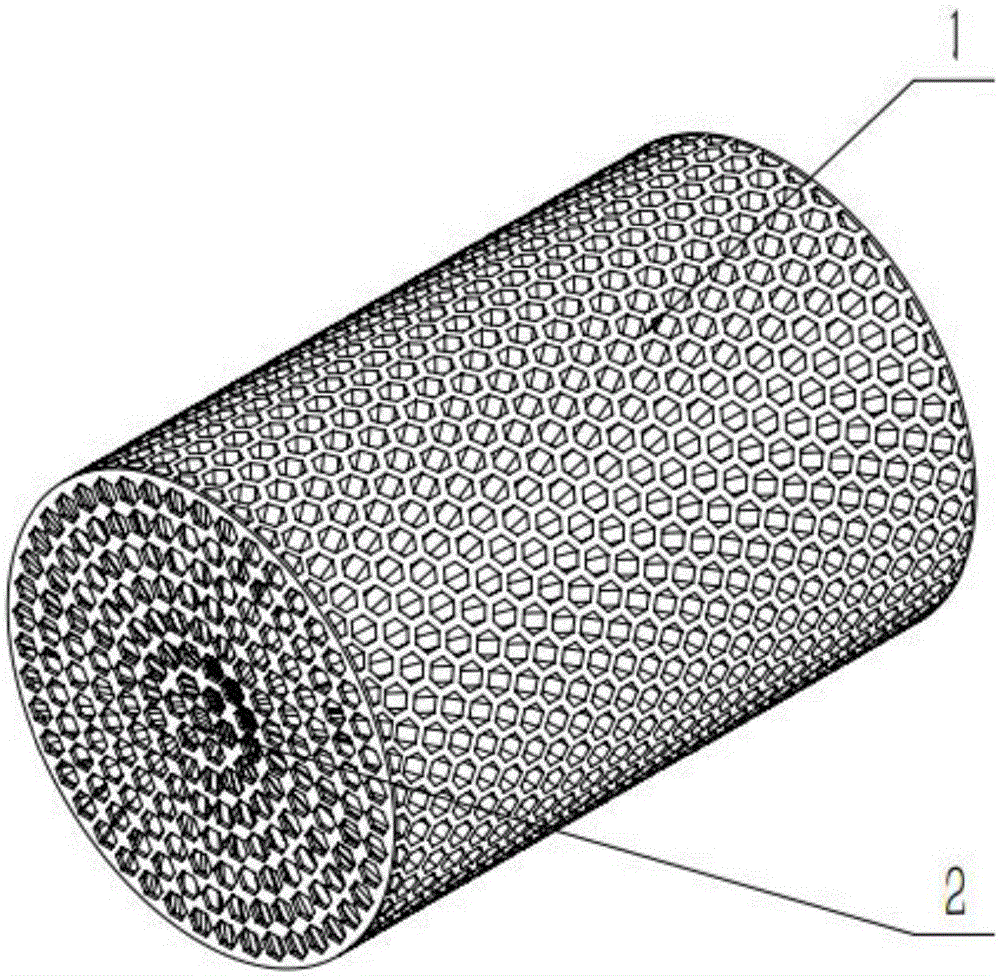

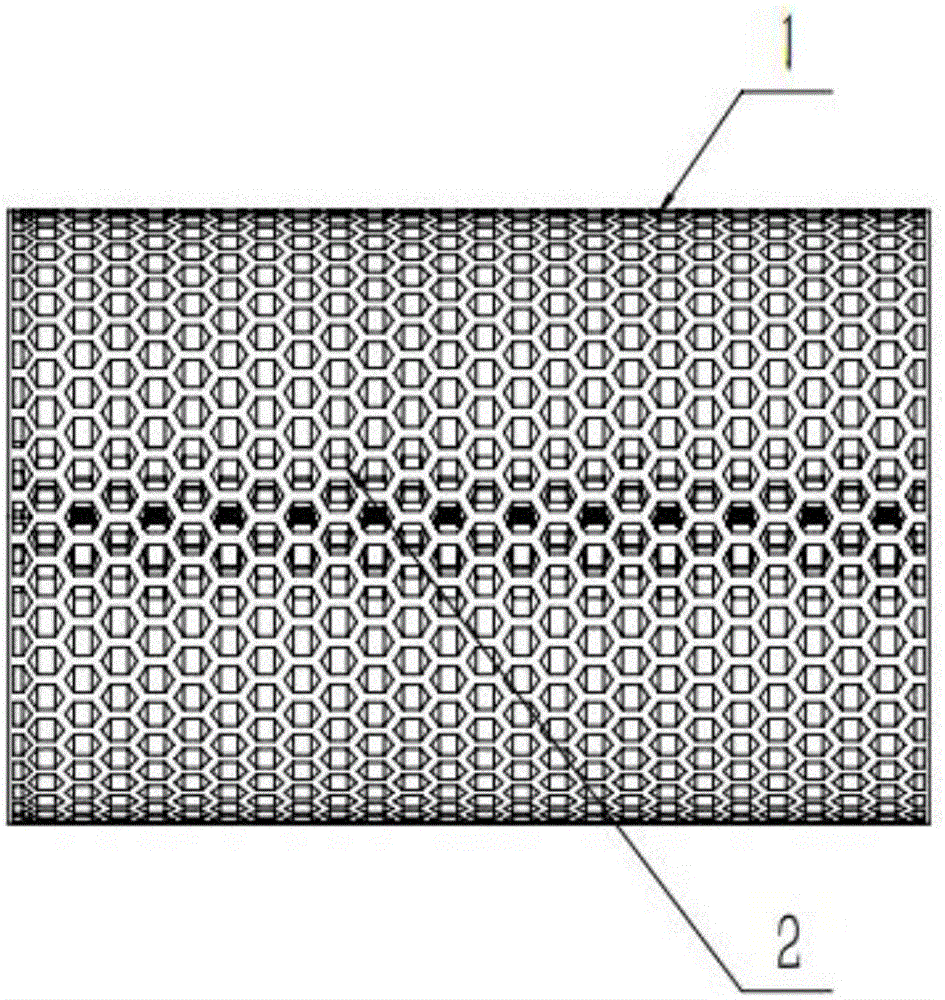

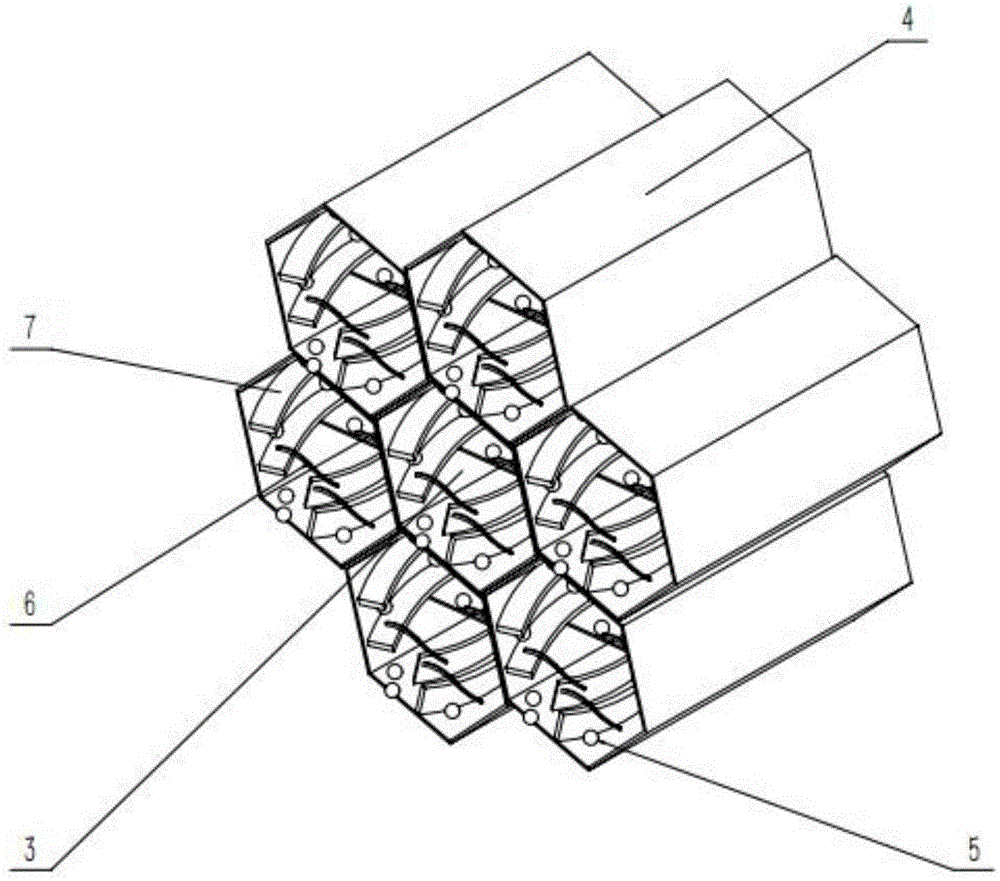

[0026] see Figures 1 to 4 , the fuel cell electrode with honeycomb cavity and electrode integration of the present invention includes a cylindrical fuel cavity 1 made by 3D printing using conductive 3D printing materials, and a number of honeycomb holes 2 are opened on the side and bottom of the fuel cavity 1, The outside of the honeycomb hole 2 is a honeycomb porous structure support layer 4; the side honeycomb hole 2 is used as the primary channel 3 of the fuel transmission channel, and the honeycomb hole 2 is provided with a secondary channel 7 for increasing the reaction surface area; The surfaces of the primary channel 3 and the secondary channel 7 are coated with a thin-film catalytic layer, and the thin-film catalytic layer includes catalyst particles 5 and ionic polymers 6 coated on the surfaces of the primary channel 3 and the secondary channel 7 .

[0027] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com