Magnetic bearing ring of micro Hall motor

A technology of a micro-Hall motor and a magnetic bearing ring, applied in the field of magnetic bearing rings, can solve the problems of uneven magnetic distribution of nylon magnetic rings, high cost of installing bushings, complicated process and high cost, and avoid uneven magnetic distribution, The effect of avoiding magnetic pole pointing deviation and simplifying the fixing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

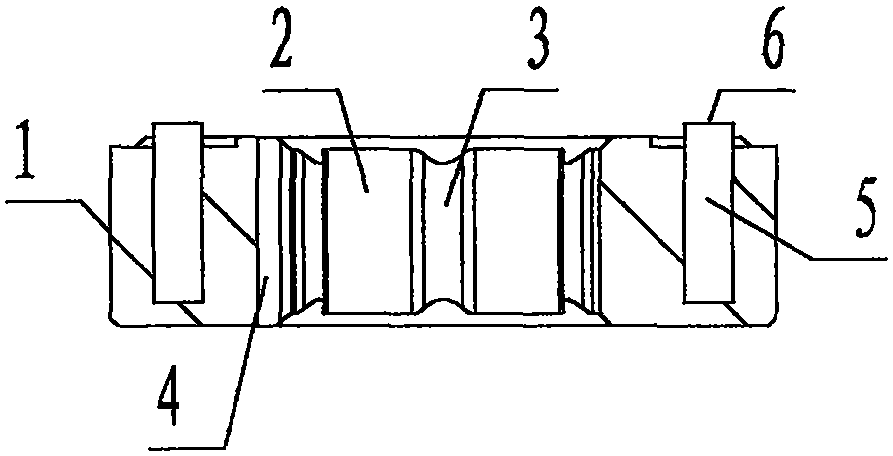

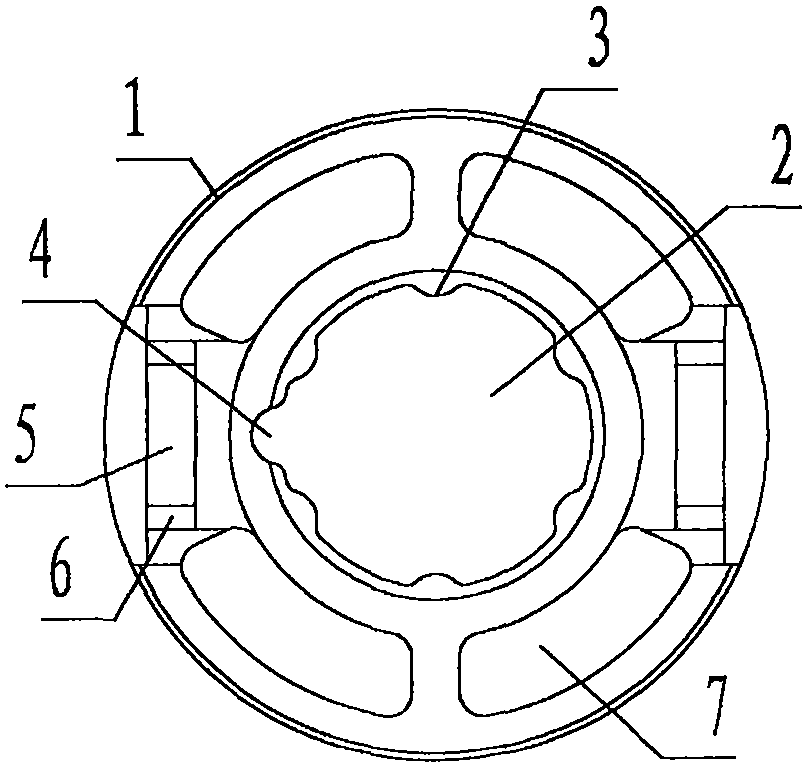

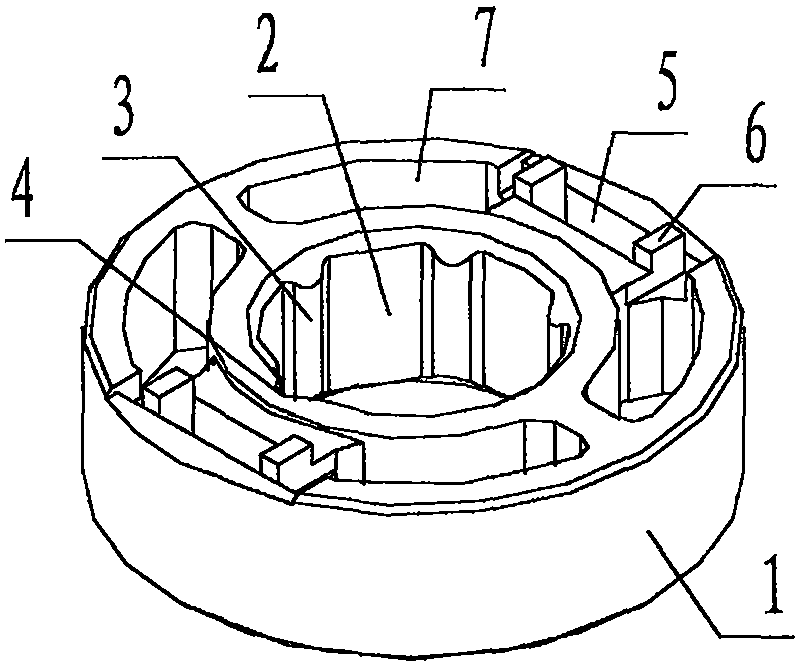

[0027] refer to Figure 1 to Figure 6 , a magnetic bearing ring of a micro-Hall motor of the present invention is composed of a ring body 1, a shaft hole 2, an interference rib 3, an orientation groove 4, a magnetic core groove 5, a heat fusion platform 6 and a mesopore 7, and the The ring body 1 is a circular cylindrical plastic member; the center of the ring body 1 is provided with a circular through hole in the up and down direction called the shaft hole 2, and the hole wall of the shaft hole 2 is evenly equipped with a number of centripetal protrusions. The protruding ribs in the exit and up and down directions are called interference ribs 3, and the left side of the hole wall of the shaft hole 2 is provided with a vertical groove with a semicircular cross section called the orientation groove 4; the left and right grooves on the ring body 1 Both sides, centering on the shaft hole 2, are symmetrically provided with rectangular grooves called magnetic core grooves 5, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com