Voltage-sharing DC capacitor system for large-power frequency converter

A technology of DC capacitors and frequency converters, applied in the field of frequency converters, can solve problems such as increasing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

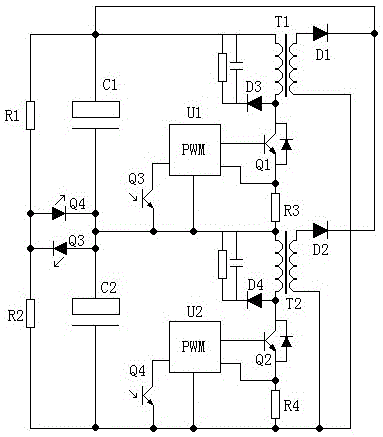

Embodiment 1

[0017] Such as figure 1 As shown, a voltage equalizing DC capacitor system for a high-power frequency converter, the high-power frequency converter voltage equalizing DC capacitor system includes a first capacitor C1, a second capacitor C2, a first boost converter, a second boost converter , a first sampling resistor R1, a second sampling resistor R2, and a signal controller, the first capacitor C1 is connected in parallel with the first boost converter, the second capacitor C2 is connected in parallel with the second boost converter, and the first A capacitor C1 is connected in parallel with the first sampling resistor R1, the second capacitor C2 is connected in parallel with the second sampling resistor R2, the first capacitor C1 is connected in series with the second capacitor C2, and the first sampling resistor R1 is connected with the second sampling resistor R2 is connected in series, the first sampling resistor R1 and the second sampling resistor R2 are respectively con...

Embodiment 2

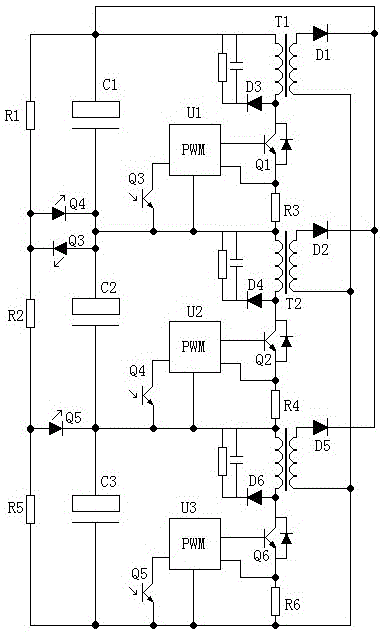

[0025] Such as figure 2 As shown, when it is necessary to equalize the voltage of three groups of capacitors in series, the figure 1 On the basis, a third boost converter is added to make C1 and C2 basically equalize the voltage, and C3 and C2 also basically equalize the voltage, which realizes the purpose of basically equalizing the voltage of the three sets of capacitors, and the mutual voltage difference does not exceed 1V.

[0026] The third boost converter includes a pulse width modulator U3, a main switch tube Q6, a current detection resistor R6, a step-up transformer T3, a rectifier diode D5, and a rectifier diode D6. The width modulator U3 is connected, the main switch tube Q6 is connected to the current detection resistor R6, the main switch tube Q6 is connected to the step-up transformer T3, and the rectifier diode D5 and the rectifier diode D6 are respectively connected to the step-up transformer T3 , the rectifier diode D5 is connected to the main switch tube Q6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com