Water-based ultraviolet curable overprint varnish composition

A technology for overprinting varnish and ultraviolet rays, applied in chemical instruments and methods, synthetic resin layered products, coatings, etc., can solve the problems of sensory evaluation, insufficient friction resistance, detachment of polyurethane resin beads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]

[0042] 27.0 parts of water-based aliphatic polyurethane dispersion with a glass transition temperature (Tg) of -80°C and an average particle size of 1.5 μm, 54.0 parts of water, 17.5 parts of N-(2-hydroxyethyl)acrylamide (HEAA), three 0.5 part of methylolpropane triacrylate (TMPTA) was mixed, stirred and dispersed using a mixer, and 2-hydroxy-2-methyl-1-phenyl-propan-1-one (DAROCUR1173, manufactured by BASF Corporation) was further added 1.0 part was used as a photopolymerization initiator, and it was dissolved completely, thereby preparing Example varnish-1.

[0043]

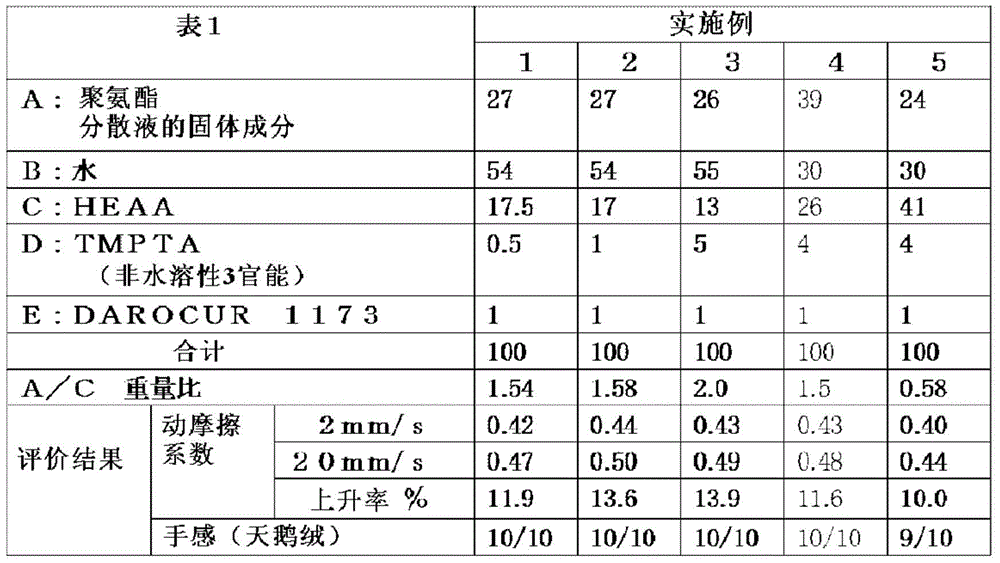

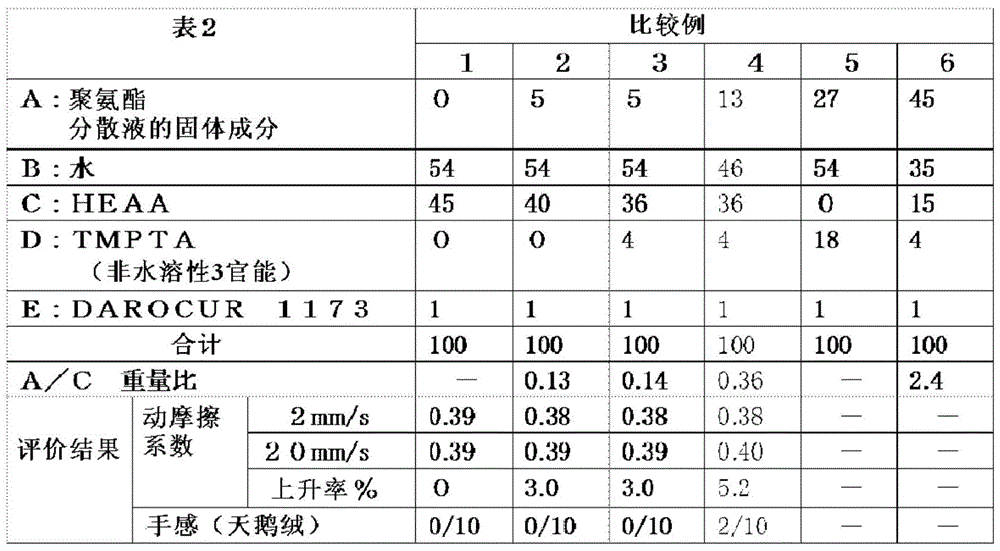

[0044] The raw materials were mixed according to the formulations shown in Table 1 and Table 2, stirred and dispersed using a mixer, and the photopolymerization initiator was completely dissolved, thereby preparing by the same method as Example Varnish-1.

[0045] The water-based ultraviolet curing type overprint varnishes (Example varnishes 1-5) and (Comparative example varnishes 1-6) prepared as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com