Modular exhaust treatment system

A technology for exhaust treatment and exhaust post-treatment, which is applied in the direction of exhaust devices, gas passages, machines/engines, etc., and can solve problems such as the infeasibility of exhaust after-treatment pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

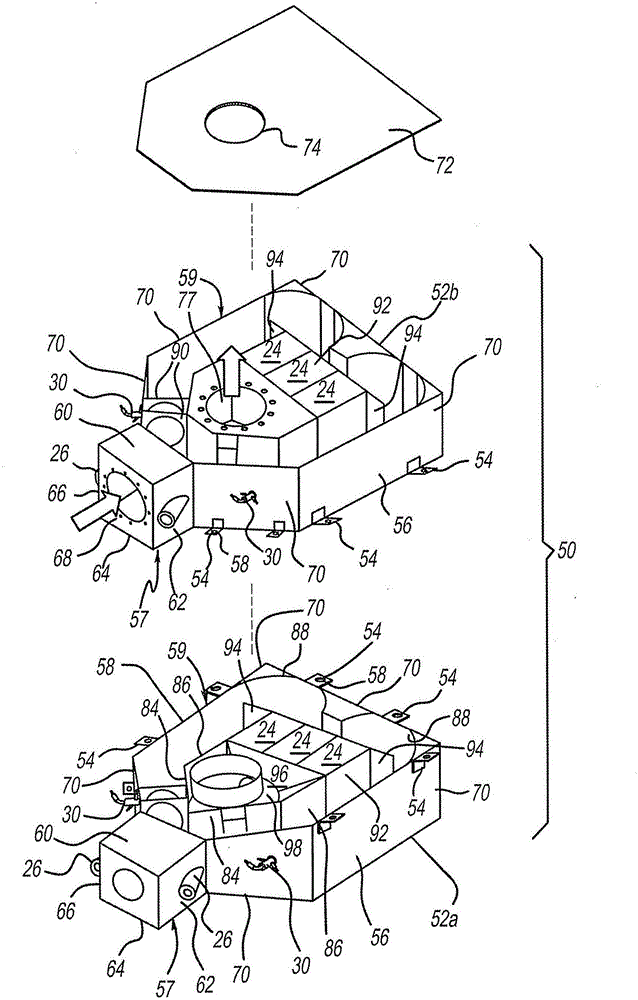

[0019] Example embodiments will now be described in more detail with reference to the accompanying drawings.

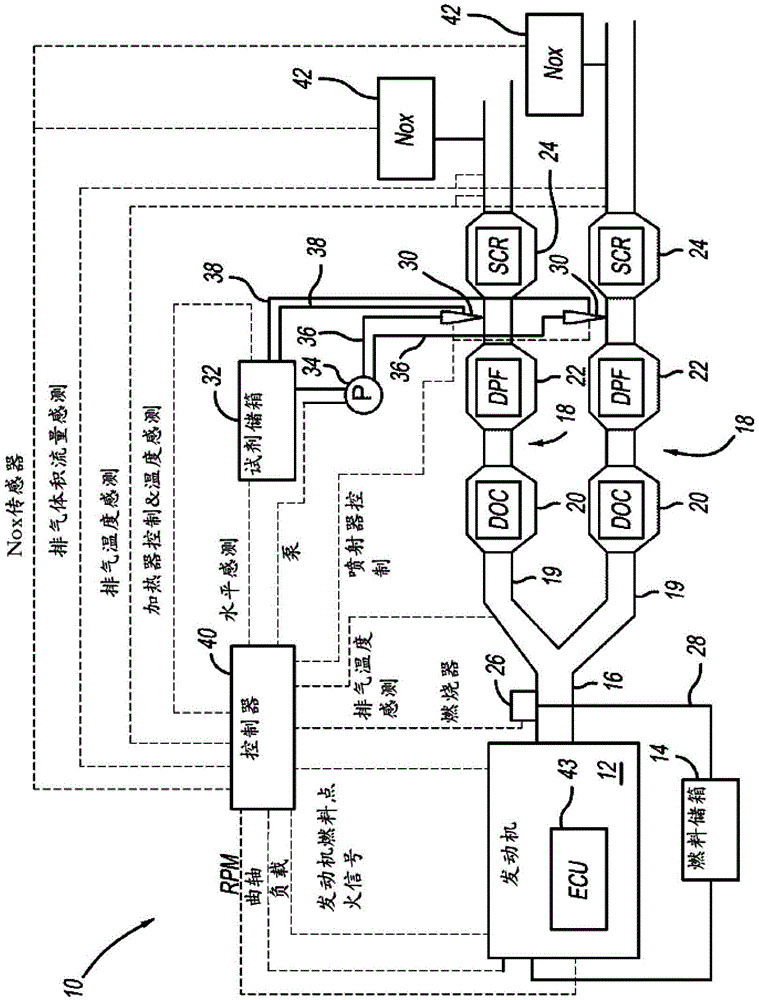

[0020] figure 1 is a schematic illustration of an exhaust system 10 according to the present disclosure. Exhaust system 10 includes at least one engine 12 in communication with a fuel source 14 that, upon consumption, produces exhaust gases that are discharged into exhaust passage 16 that includes an exhaust aftertreatment system 18 . The exhaust system 10 may be designed as a multi-branch system with a plurality of exhaust lines 19 each comprising an aftertreatment system 18 . although figure 1 Only one pair of exhaust lines 19 are shown, it being understood that a greater number of exhaust lines 19 may be used depending on the size of the engine 12 and the resulting exhaust flow rate without departing from the scope of the present disclosure.

[0021] Each exhaust aftertreatment system 18 may include a diesel oxidation catalyst (DOC) component 20 , a diesel parti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap