A kind of spiral blade machine beating type sunflower head peeling machine

A technology of helical blade and head stripper, applied in agricultural machinery and implements, threshing equipment, applications, etc., can solve the problems of high crushing efficiency, waste, labor intensity of workers, etc., achieve high crushing efficiency, reduce waste, equipment simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

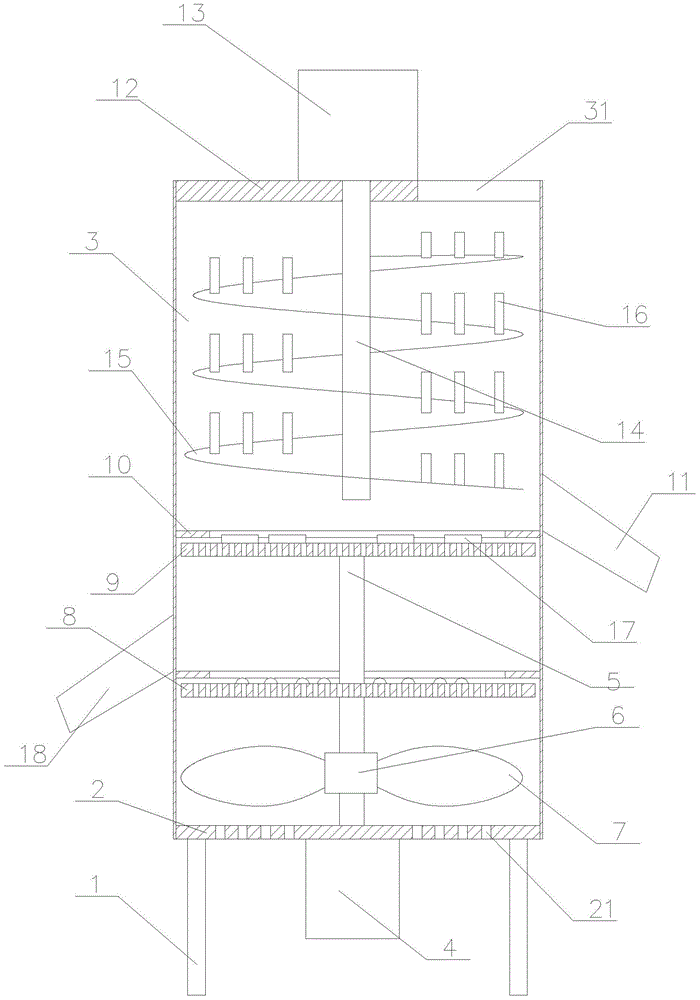

[0016] refer to figure 1 and figure 2 , a kind of helical blade machine-type sunflower head stripping machine of the present invention comprises a lower leg 1, a bottom plate 2, a cylinder body 3, a filter material motor 4, a filter material shaft 5, a leaf fan seat 6, a leaf fan 7, a first Filter disc 8, second filter disc 9, upper cover plate 12, crushing motor 13, screw blade 15, crushing rod 16, scraping block 17 and screw shaft 14, the lower part of the bottom plate 2 is provided with a lower leg 1, The upper part of the base plate 2 is provided with a cylinder body 3, and the lower part of the base plate 2 is fixed with a filter material motor 4 by bolts. The filter material motor 4 is provided with a filter material shaft 5, and the filter material shaft 5 is provided with a blade Fan seat 6, two leaf fans 7 are installed on the leaf fan seat 6, a first filter disc 8 is arranged on the upper part of the leaf fan seat 6, a second filter disc 9 is arranged on the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com