Automatic positioning technology of main shaft of machine tool in field processing

A machine tool spindle, on-site processing technology, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve problems such as limited means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

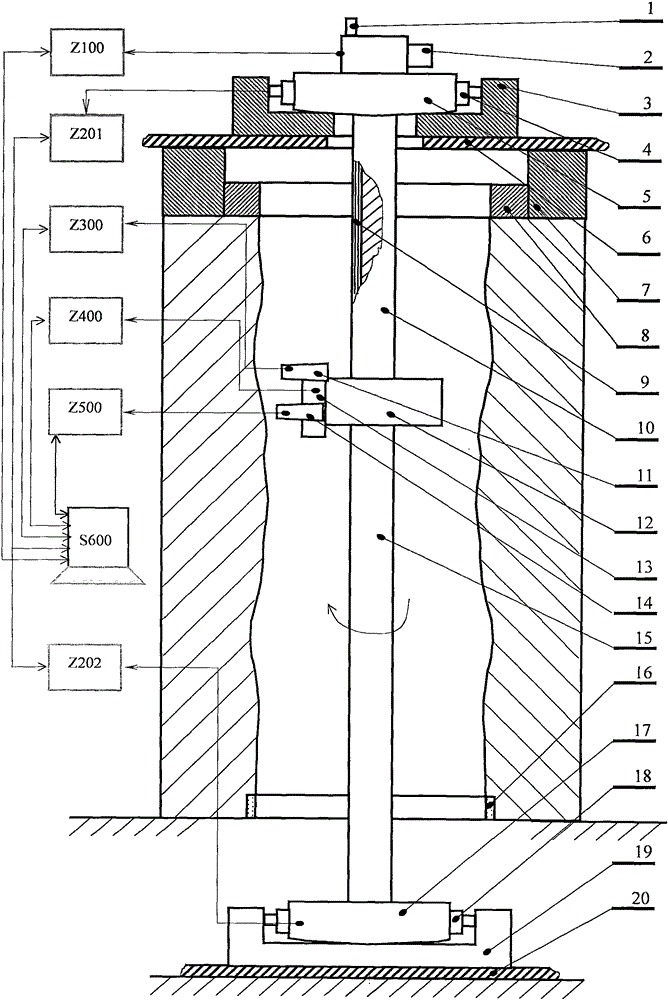

[0025] Such as figure 1 As shown, firstly, the machine tool is initially hoisted and fixed in the hole of the machined part, so that the machining spindle of the machine tool is roughly consistent with the axis of the machined hole and fixed. Secondly, the installation includes the spindle and the spindle drive device Z100, the spindle centering adjustment device Z201 and the spindle centering adjustment device Z202, the spindle position detection device Z300, the tool post axial feed device Z400, the tool post radial feed device Z500 and a comprehensive Control system Z600, etc.

[0026] Then establish the datum axis. The present invention adopts two methods for establishing the reference axis: one is to use the standard ring method, and the joint axis determined by the centers of two or more standard rings is used as the reference axis; in this method, the standard ring can also use a pre-set process The datum plane is replaced, that is, the datum axis is the joint axis es...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com