A construction method of prefabricated exterior concrete joint structure of prefabricated exterior walls

A technology of fair-faced concrete and construction methods, applied to building structures, walls, building components, etc., can solve the problems of ineffective drainage at joints, uneven width of joints, color difference of external wall components, etc., to reduce construction costs, Ease of construction and reduction in repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

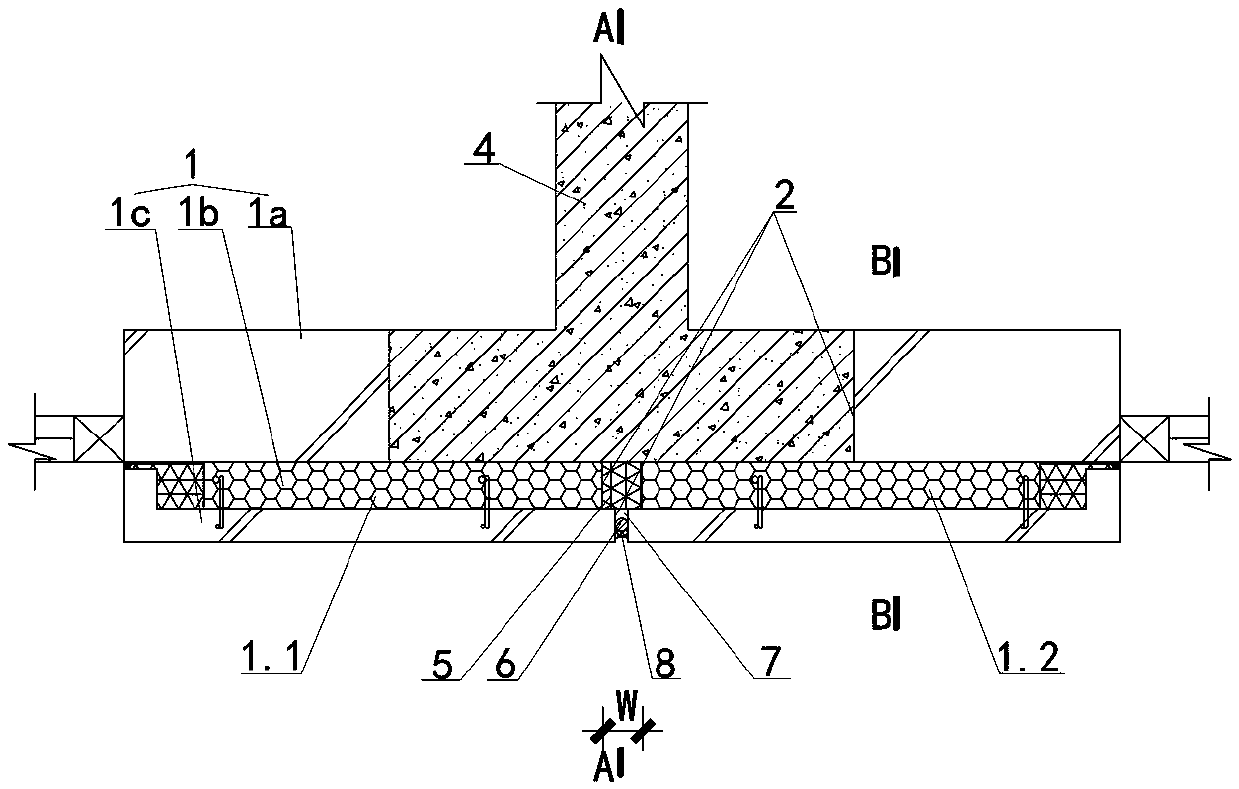

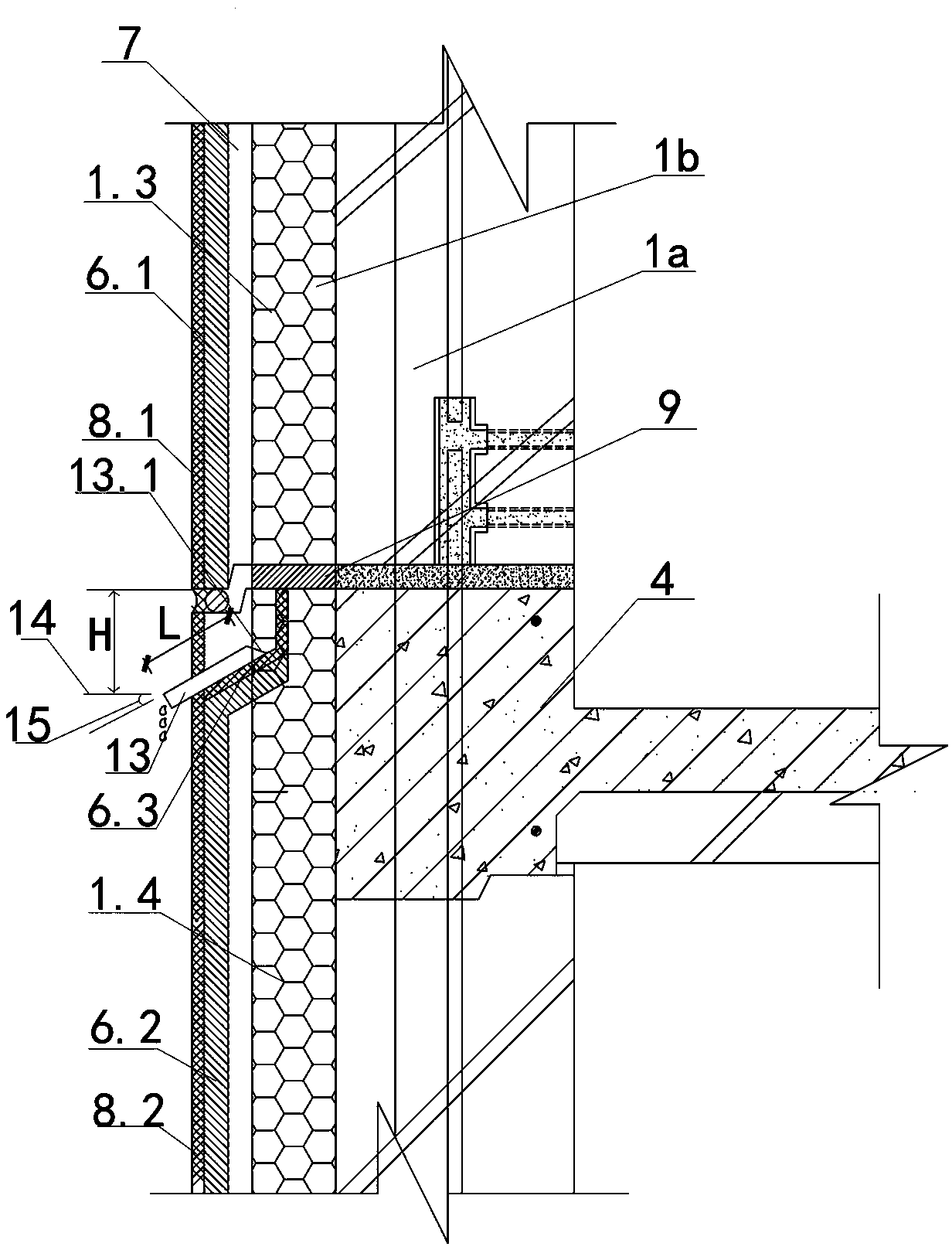

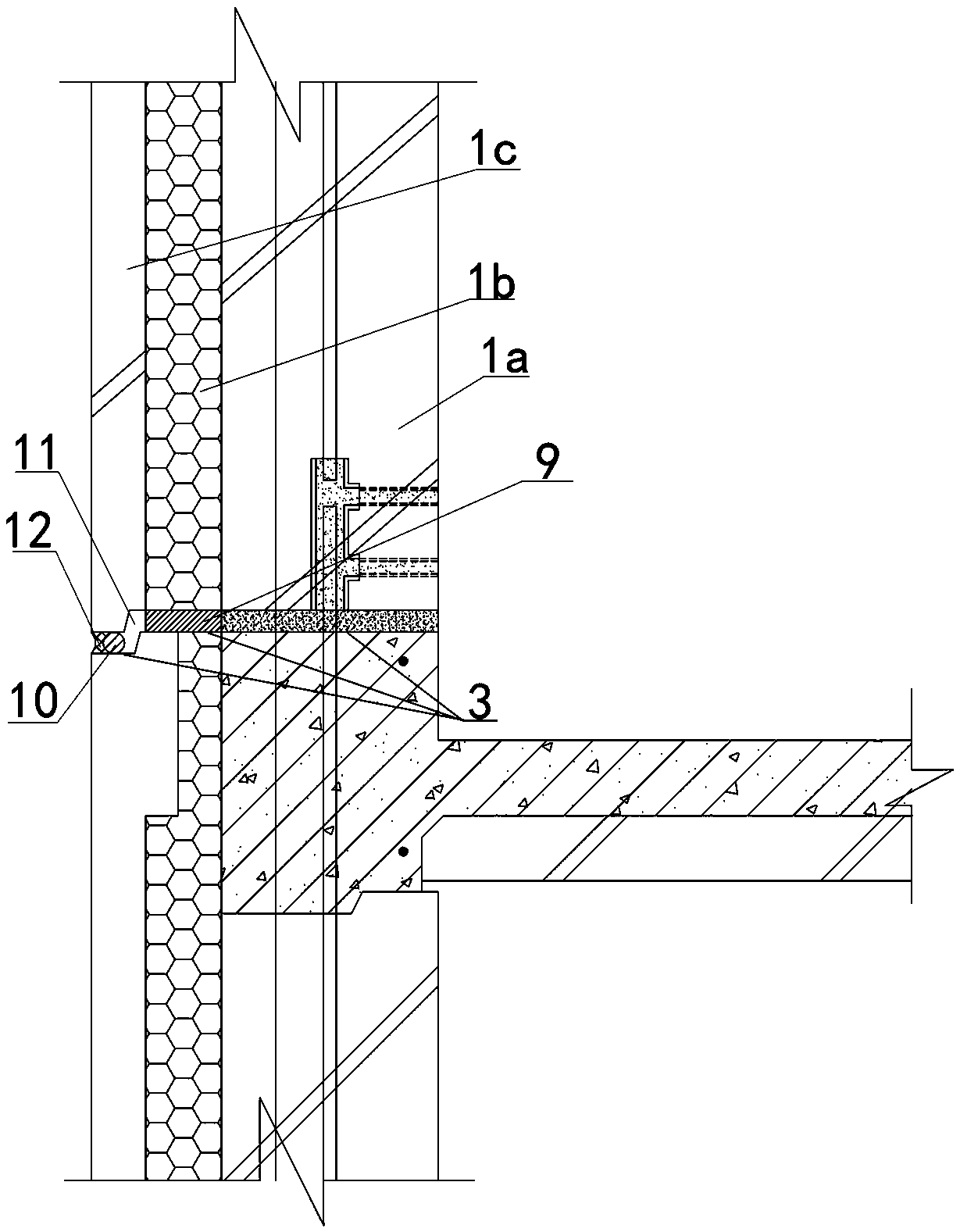

[0074] Examples see Figure 1-3 As shown, an assembled prefabricated external wall fair-faced concrete joint structure includes two prefabricated external wall panels 1 adjacent to the left and right, up and down, and the left prefabricated external wall panel 1.1 and the right prefabricated external wall panel 1.2 form a vertical joint. joint 2, the upper prefabricated exterior wall panel 1.3 and the lower side prefabricated exterior wall panel 1.4 form a horizontal joint 3, and the intersection of the vertical joint 2 and the horizontal joint 3 forms a cross joint, and the prefabricated exterior wall panel includes an inner layer The sandwich wall panels of reinforced concrete load-bearing slab 1a, middle layer insulation board 1b and outer layer panel 1c. In this embodiment, a sandwich insulation exterior wall panel with a total thickness of 320mm is used. The outermost side is an outer panel 1c with a thickness of 50mm, and the middle is a middle insulation board 1b with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com