Numerical control automatic alloy saw blade gear grinding machine

A saw blade grinding machine and saw blade technology, which is applied to metal sawing equipment, metal processing equipment, sawing machine tool trimming, etc., can solve the problem of automatic swinging of the sawtooth inclination angle and the inability of the automatic gear shifting device to work , sawtooth inclination angle and other problems, to achieve the effect of labor cost saving, light weight and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

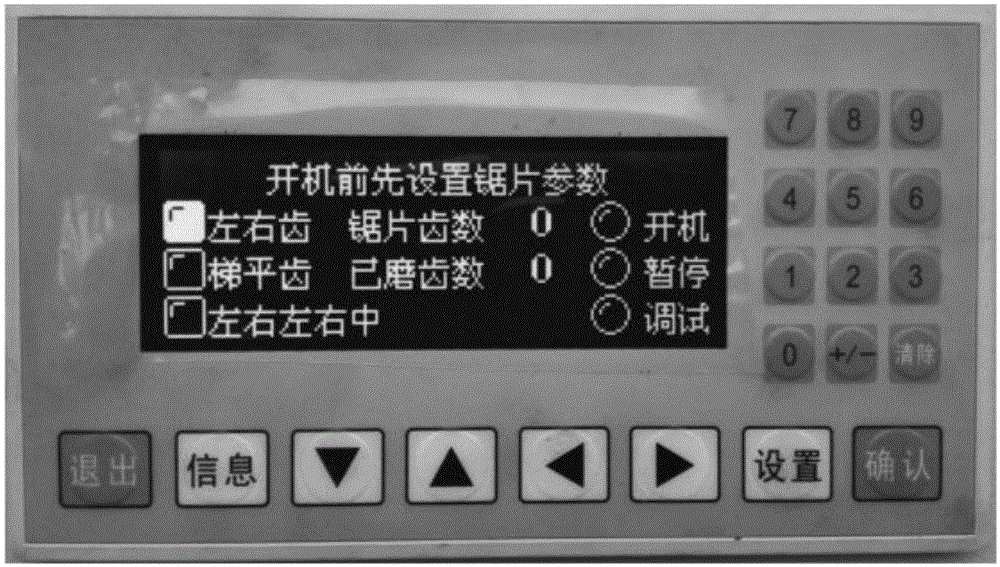

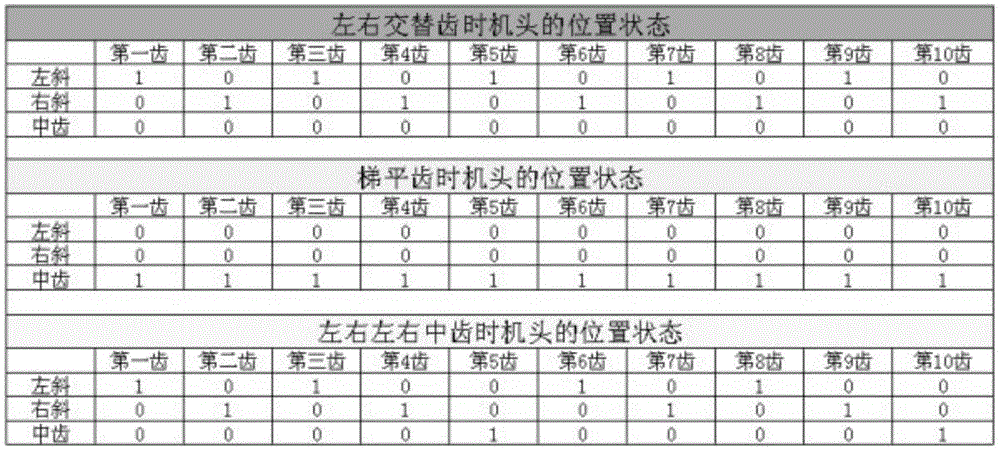

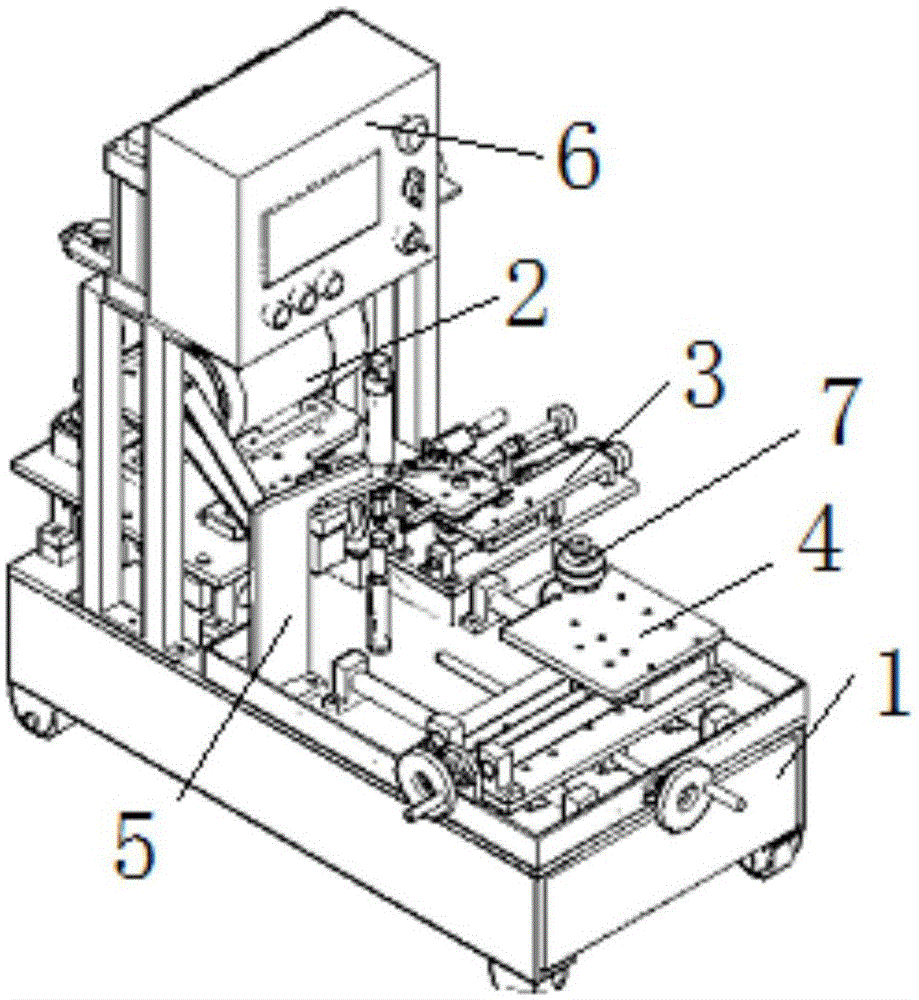

[0039] combine figure 1 , which is a structural schematic diagram of an embodiment of the CNC automatic alloy saw blade gear grinding machine of the present invention, including a body 1, the body 1 includes a base with a moving wheel and a tablet pressing mechanism 5, and the base and the tablet pressing mechanism 5 are above One end of the blade is provided with a saw blade adjustment mechanism 4, and the other end is provided with a grinding disc feeding and swing mechanism 2, and the upper part of the grinding disc feeding and swinging mechanism 2 is provided with a control box and a hydraulic assembly 6, and the saw blade adjusting mechanism 4 A tooth pushing mechanism 3 is arranged between the grinding disc feeding and swinging mechanism 2, and a saw blade thickness adjusting mechanism 7 is arranged on the saw blade adjusting mechanism 4.

[0040] The machine has functions such as automatic tooth shifting (pushing teeth), automatic swing angle of the grinding disc, autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com