Machining technology of thick plate cylinder of aluminum power generation shell

A processing technology and cylinder technology, applied in the field of thick plate cylinder processing technology, can solve the problem of workpiece cleaning threat, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] refer to figure 1 The embodiments of the present invention will be further described.

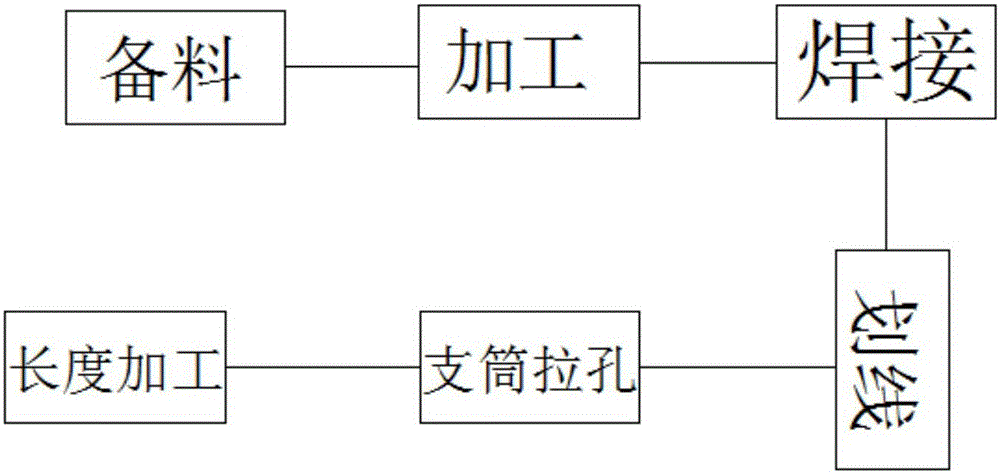

[0017] A process for processing a thick plate cylinder of an aluminum power generation casing, the process steps are as follows: material preparation, processing, welding, marking, opening the cylinder hole and length processing;

[0018] (1) Material preparation: prepare the plate for processing the cylinder;

[0019] (2) Processing: the plate is rolled into a cylindrical cylinder by a plate rolling machine;

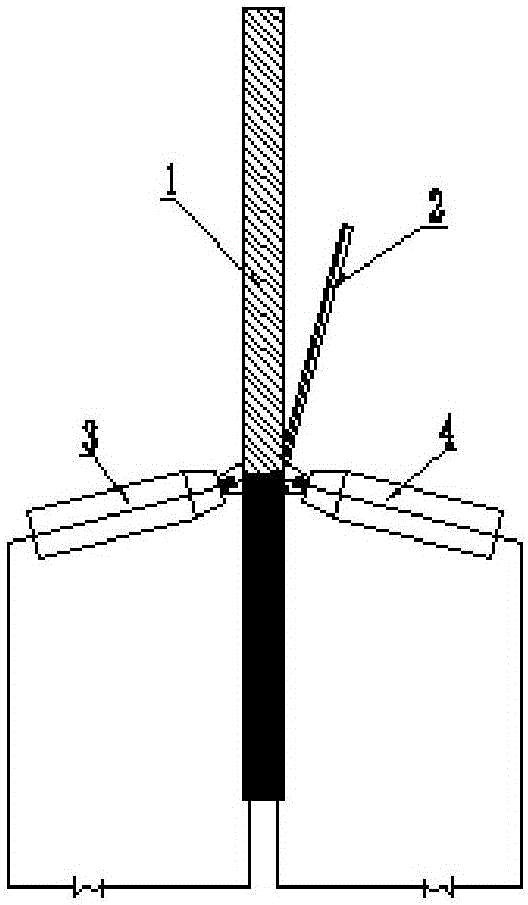

[0020] (3) Welding: welding is carried out at the junction of the two sides of the cylinder, welding is performed at the joint outside the cylinder through the first welding torch, and then welding is carried out with the first welding torch outside the cylinder through the connection of the second welding torch inside the cylinder;

[0021] (4) Marking: by marking the side of the cylinder;

[0022] (5) Cylinder opening: open the cylinder through the opening equipment;

[...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap