A large-diameter nickel-based composite pipe x groove welding method without argon back filling

A welding method and technology for composite pipes, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of affecting the integrity and plasticity of welded joints, expensive nickel-based alloy welding materials, and high interlayer temperature, etc. The effect of saving gas filling time, saving welding time, and thickness of deposited metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

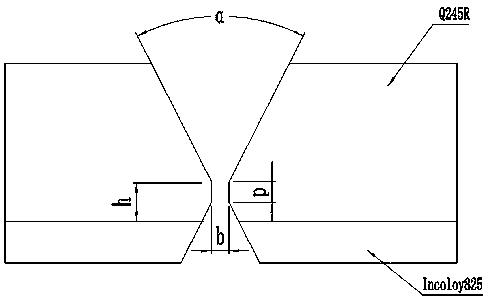

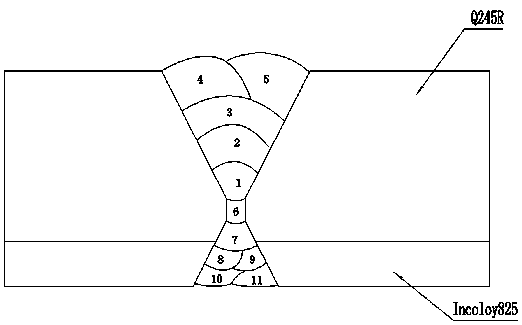

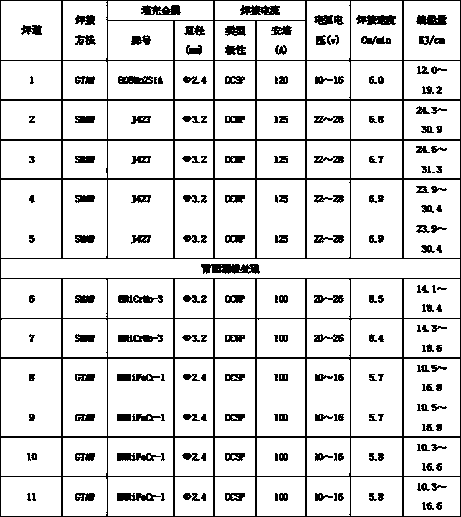

[0028] The nickel-based alloy composite pipe welded in this example has a pipe diameter of Φ508mm, a base layer Q245R with a thickness of 16mm, and a clad Incoloy825 with a thickness of 5mm. figure 1 It is an X-shaped groove of the annular weld, the groove angle α is 65°, the root gap b is 2mm, the blunt edge length p is 2mm, and the distance h from the root of the base groove to the base and the cladding surface is 3mm.

[0029] The welding step is as follows: machining grooves on the end faces of the two nickel-based alloy composite pipes to be welded, and then connecting the two ends to form a circular weld, and the circular weld is in the shape of a circular weld. figure 1 The X-shaped groove shown; double-sided welding is adopted, the base layer is first welded with a carbon steel wire electrode, and then the transition layer and the cladding layer are welded in turn with a nickel-based alloy wire electrode; the entire welding process does not use argon gas back protection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com