Integrated hot wire submerged arc welding device assisted by magnetic field

A magnetic field-assisted submerged arc welding technology, which is applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of high equipment cost, reduced welding efficiency, and limited core technology, so as to improve product quality and fast heating speed , the effect of reducing heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

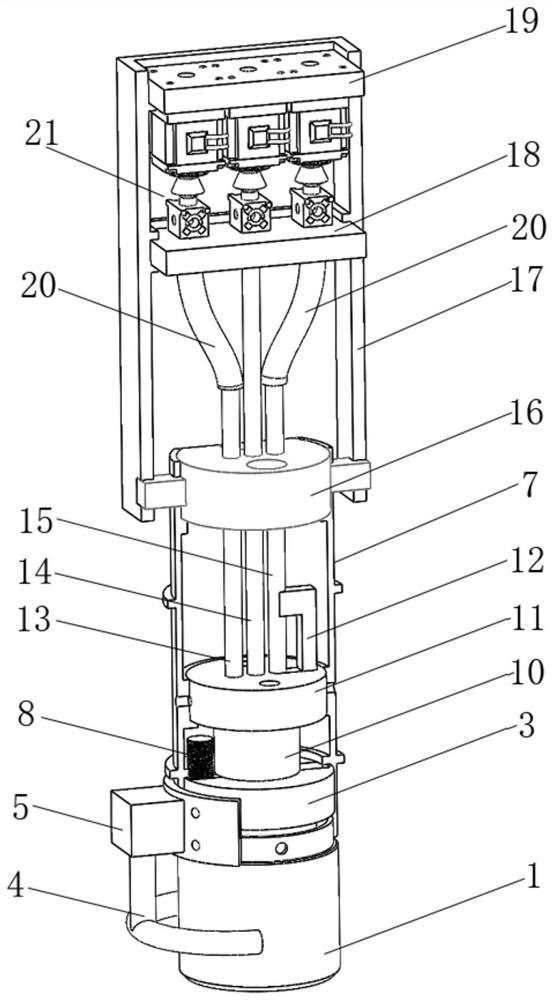

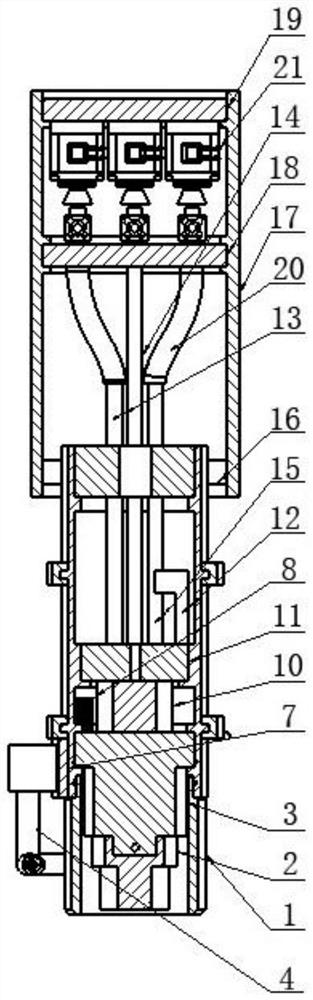

[0036] In order to facilitate the understanding of the present invention, the present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments. Preferred embodiments of the invention are shown in the accompanying drawings. However, the present invention can be implemented in many different forms and is not limited to the embodiments described in this specification. On the contrary, these embodiments are provided to make the understanding of the disclosure of the present invention more thorough and comprehensive.

[0037] As introduced in the background technology, in order to improve the welding deposition rate and reduce the welding heat input, the present invention adjusts the power supply of the hot wire. When the arc is struck, the rear wire is preheated by the auxiliary power supply, and the temperature control system slowly increases the heating process, and There is gradient temperature compensation, which ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap