Locking mechanism for machining outer teeth of rib pipe

A locking mechanism and tooth processing technology, applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of low precision of the connection and cooperation between the screw and the fixture, and the rib tube cannot meet the requirements, etc., to achieve improvement Processing accuracy and product yield, the effect of preventing twisting or moving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

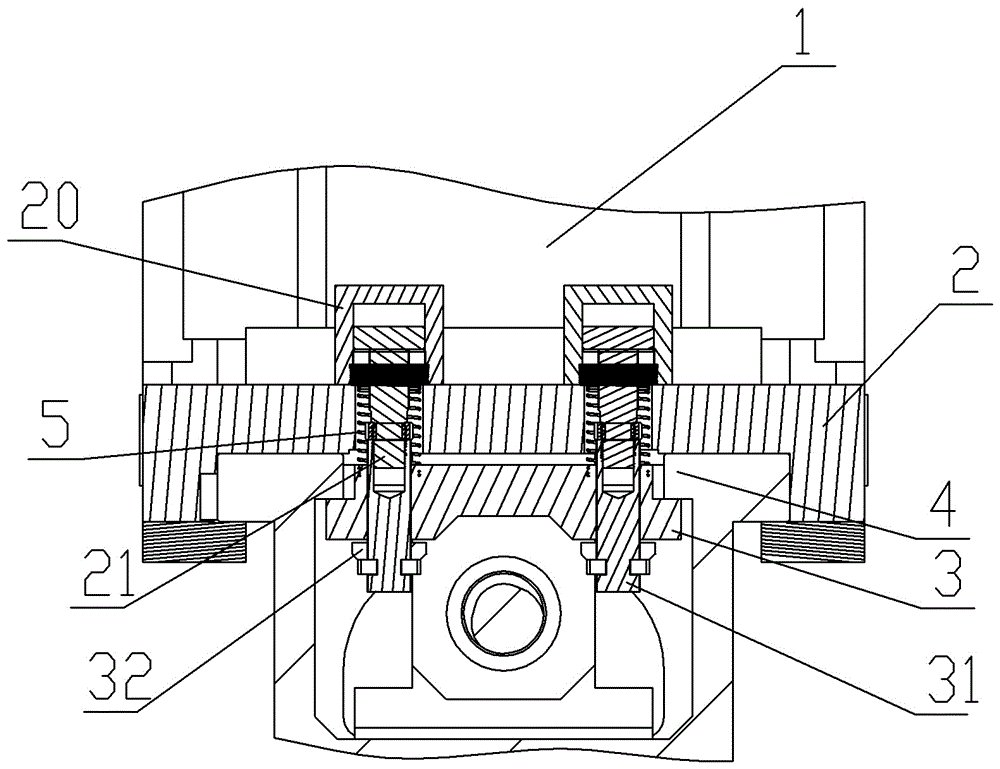

[0014] Such as figure 1 As shown, the locking mechanism for processing the external teeth of the rib tube, the locking mechanism for processing the external teeth of the rib tube, includes the boss 4 arranged in the slide rail and the slider 2 arranged at the lower part of the fixture 1 to cooperate with the slide rail track, and It includes a pressure block 3 that can be pressed against the boss 4 under the inner boss 4 of the slide rail, a cylinder 20 arranged on the slider 2, and a spring 5 connecting the pressure block 3 and the slider 2; the cylinder 20 is connected There is a sliding rod 21, and a through hole is provided on the pressing block 3 corresponding to the channel of the sliding block 2, and a connecting rod 31 is arranged in the through hole, one end of the connecting rod 31 is threadedly connected with the sliding rod 21, and the other end of the connecting rod 31 is provided with an anti-off The stopper 32 is convenient to disassemble and install, and the st...

Embodiment 2

[0017] The difference from the first embodiment is that the pressing block and the sliding rod are integrated, the pressing block is provided with a spring seat, one end of the spring is located on the spring seat, and the other end is fixed on the sealing cover.

Embodiment 3

[0019] The difference from Embodiment 1 is: the slider is fixed with a pressure block that can be pressed against the lower part of the boss, the bottom end of the slider is pressed on the boss, the spring is sleeved on the slider, and one end of the spring is against the bottom of the slider. The other end of the spring is against the top surface of the boss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com