Low-noise hydraulic reinforced concrete crushing and separating equipment

A technology of reinforced concrete and separation equipment, applied in solid separation, magnetic separation, removal of smoke and dust, etc., can solve the problems of limited use scenarios of jaw crushers, limitations of waste crushing, inability to crush waste, etc., to avoid conveyor belt loss, improve ability, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

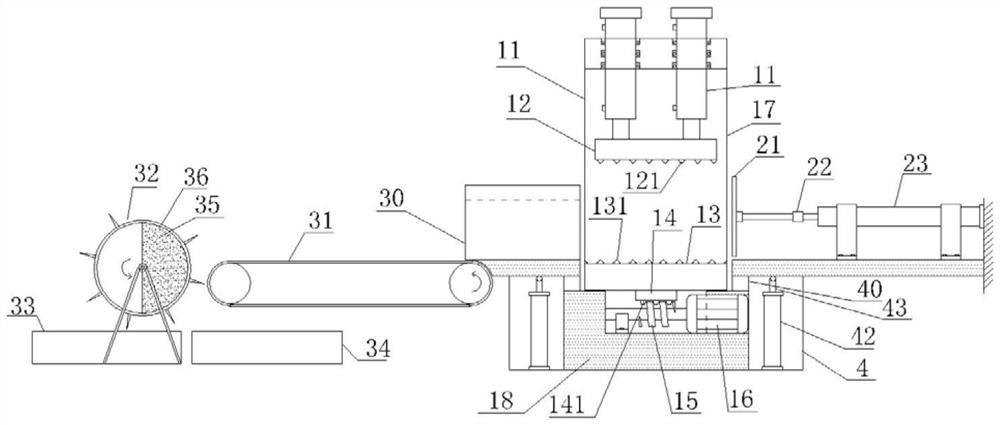

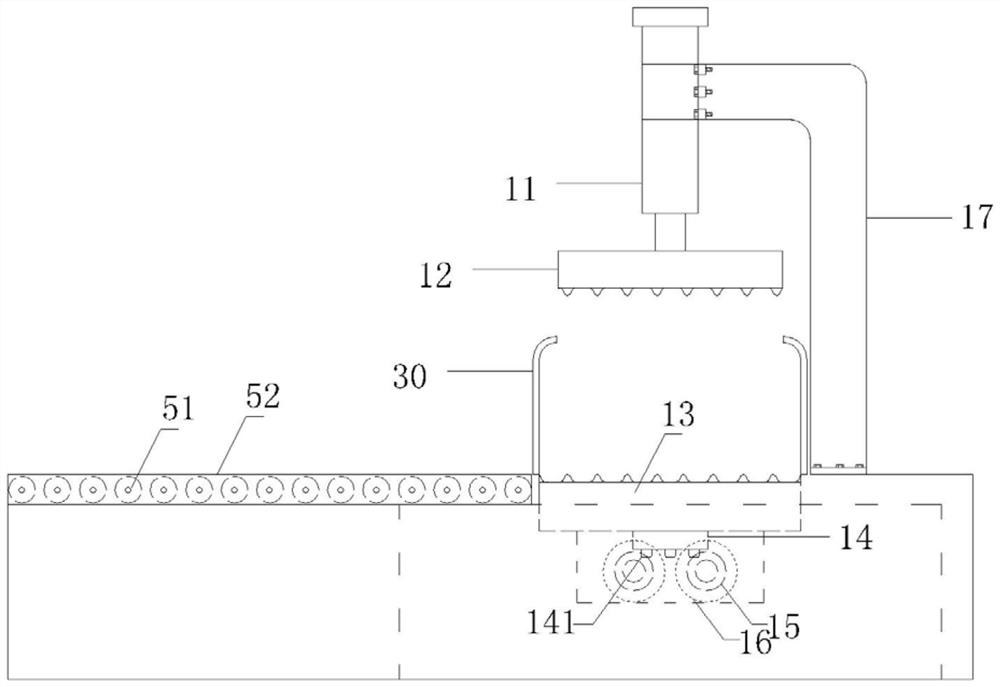

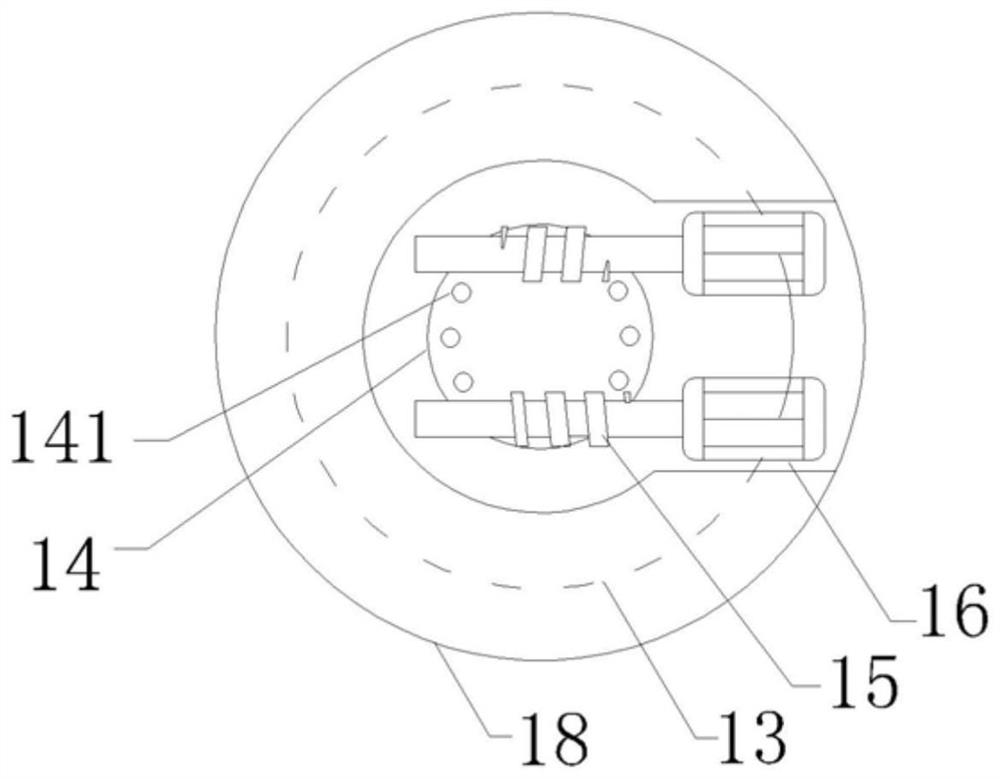

[0031] Embodiment one: if Figure 1-6As shown, a low-noise hydraulic reinforced concrete crushing and separating device of the present invention includes a frame, a feeding mechanism arranged on the frame, a pushing mechanism, a vertical crushing mechanism, a shearing and crushing mechanism, a dust collection device, a reinforced concrete Separation and collection mechanism, hydraulic control system, electrical system and controller, vertical crushing mechanism includes column 17 arranged on the frame, two hydraulic oil cylinders 11 installed on the column 17, and a pressure cylinder installed on the piston rod of the lower part of hydraulic oil cylinder 11. Hammer 12 and the anvil 13 facing the pressure hammer 12; the shearing and crushing mechanism includes a rotating disk 14 arranged on the lower frame of the anvil 13, a driving motor 16 and a driving rotating disk arranged on the output shaft of the driving motor 16 and the lower part of the rotating disk 14 14 make the tr...

Embodiment 2

[0039] Embodiment 2: On the basis of Embodiment 1, the transmission mechanism is replaced by the worm screw 15 installed on the output shaft of the drive motor 16 and the worm wheel that is arranged on the bottom of the turntable 14 and matches the worm screw 15. Drive and worm screw 15 cooperate with worm gear to do continuous rotary motion.

Embodiment 3

[0040] Embodiment 3: On the basis of Embodiment 1 or Embodiment 2, the motor box 18 is provided with a lifting seat, and the drive motor 16 is installed on the lifting seat. The lifting seat is driven by a cylinder, and the lifting seat controls the expansion and contraction of the cylinder piston rod through the controller. Realize lifting action. The lifting seat is driven by cylinder or oil cylinder. When the turntable 14 needs to rotate, the controller controls the lifting seat to rise, so that the transmission mechanism of the drive turntable 14 on the output shaft of the drive motor 16 and the bottom of the turntable 14 is matched. When there is no need to drive the turntable 14 to rotate, the controller controls the lifting seat to descend, so that the transmission mechanism is separated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com