Biomass molding machine push rod dust blocking device

A biomass molding machine, dust blocking technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of dust easily sticking to the push rod, polluting lubricating oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

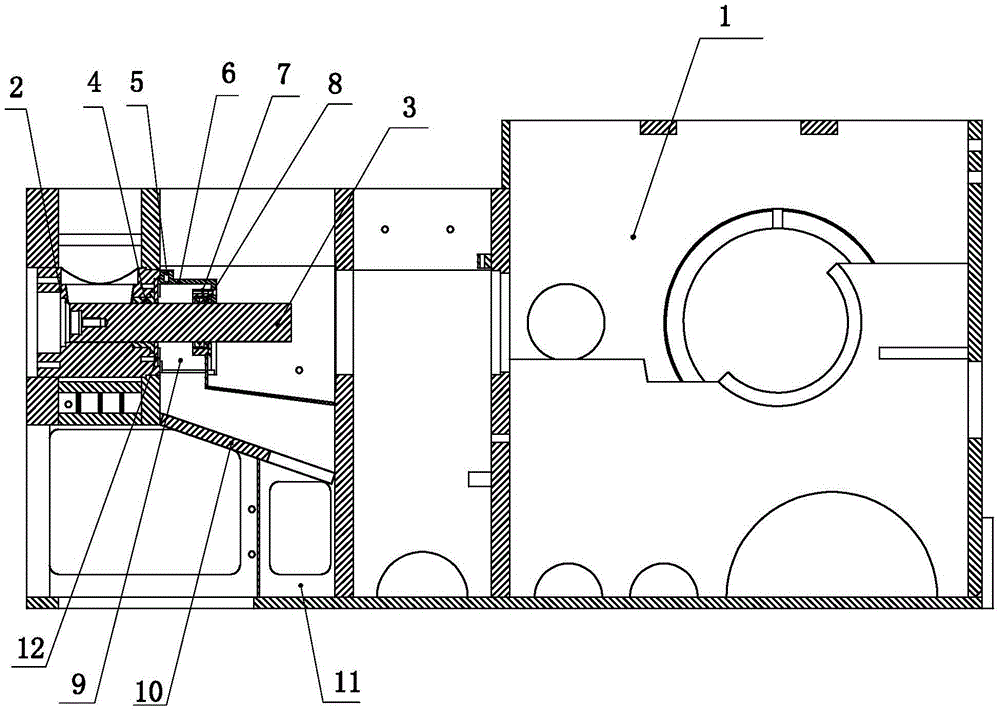

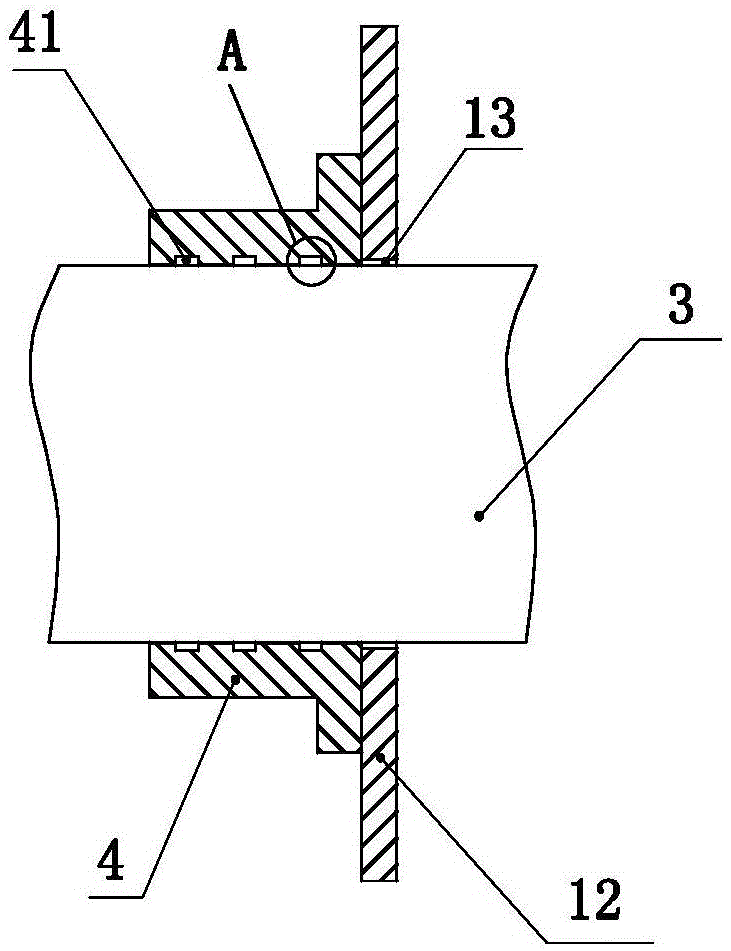

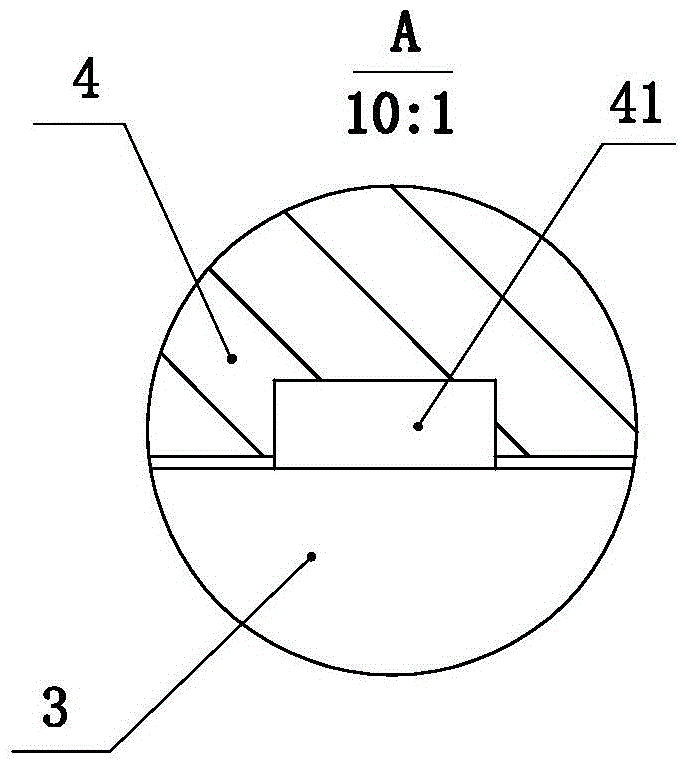

[0020] Such as Figure 1 to Figure 5 As shown, the present invention mainly includes casing 1, push rod 3, material retaining sleeve 4, dustproof seat 6, dustproof ring seat 7, dustproof ring 8, inclined plate 10, dust storage box 11 and mounting plate 12, below The present invention is described in detail in conjunction with the accompanying drawings.

[0021] Such as figure 1 As shown, the casing 1 is the main body of the biomass molding machine, and the aggregate mold 2 is arranged on the left side of the casing, the biomass in the hopper continuously enters into the aggregate mold, and the aggregate mold is installed on the right side Push rod 3, the push rod approaches or moves away from the aggregate mold under the drive of the cam linkage mechanism, the driving end of the push rod is connected with the cam linkage mechanism, and the active end of the push rod is used to extrude the biomass in the aggregate mold, To achieve the compaction of biomass. The push rod perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com