A Track Broken Monitoring System for Intervals

A monitoring system and interval technology, applied in the field of rail transit, can solve the problems of inability to use seamless line monitoring, inability to monitor the complete state of rails in real time, inability to detect rail breaks and their fault locations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with accompanying drawing.

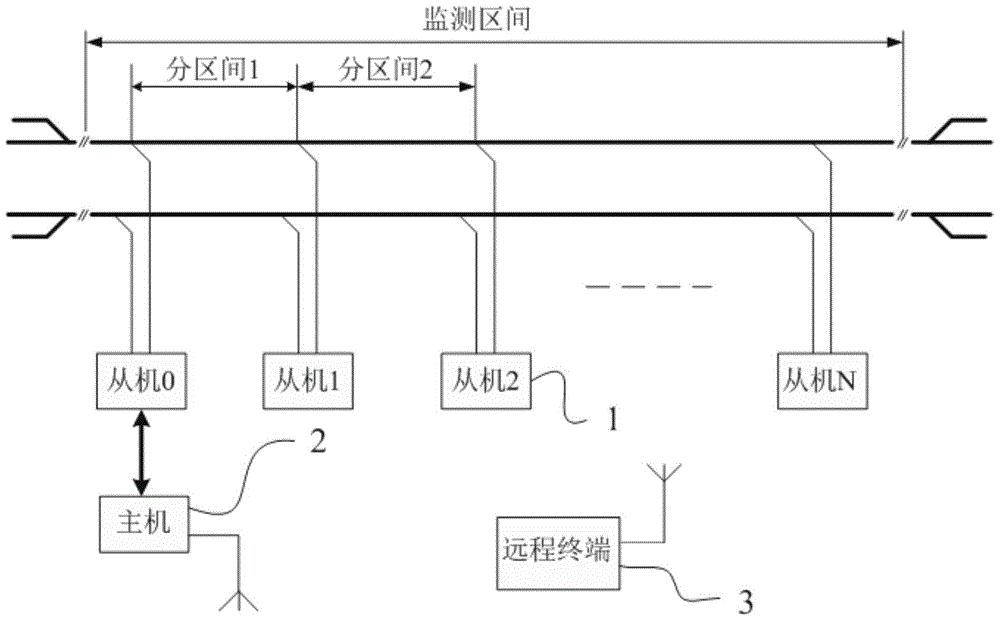

[0051] see figure 1 , divide the monitoring interval into rails in each interval. The section rail broken monitoring system of the present invention includes: a plurality of slave machines 1 correspondingly connected to the rails in each section, a host 2 and a remote terminal 3 wirelessly connected to the host 2 . The slave machines 1 are connected through steel rails to realize step-by-step power carrier communication loaded on the steel rails. Master 2 is connected to a slave 1 via a cable.

[0052] Each slave machine 1 collects its own slave machine status information and the rail status information of the rails in each section, relays and transmits them in the form of power carrier, and finally transmits them to the host machine 2 . A timing synchronization mechanism is introduced between the slaves 1, that is, at the same time, only one slave 1 sends information, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com