Coal conveying and handling device

A technology of handling device and transportation device, which is applied in transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of affecting transportation speed and efficiency, difficult to complete transportation machinery, cumbersome access operation, etc., to achieve reasonable structure and automation. The effect of high degree and strong control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

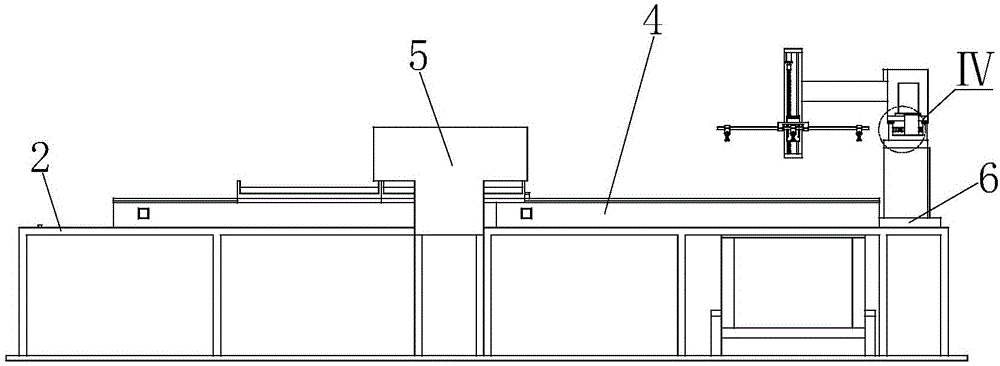

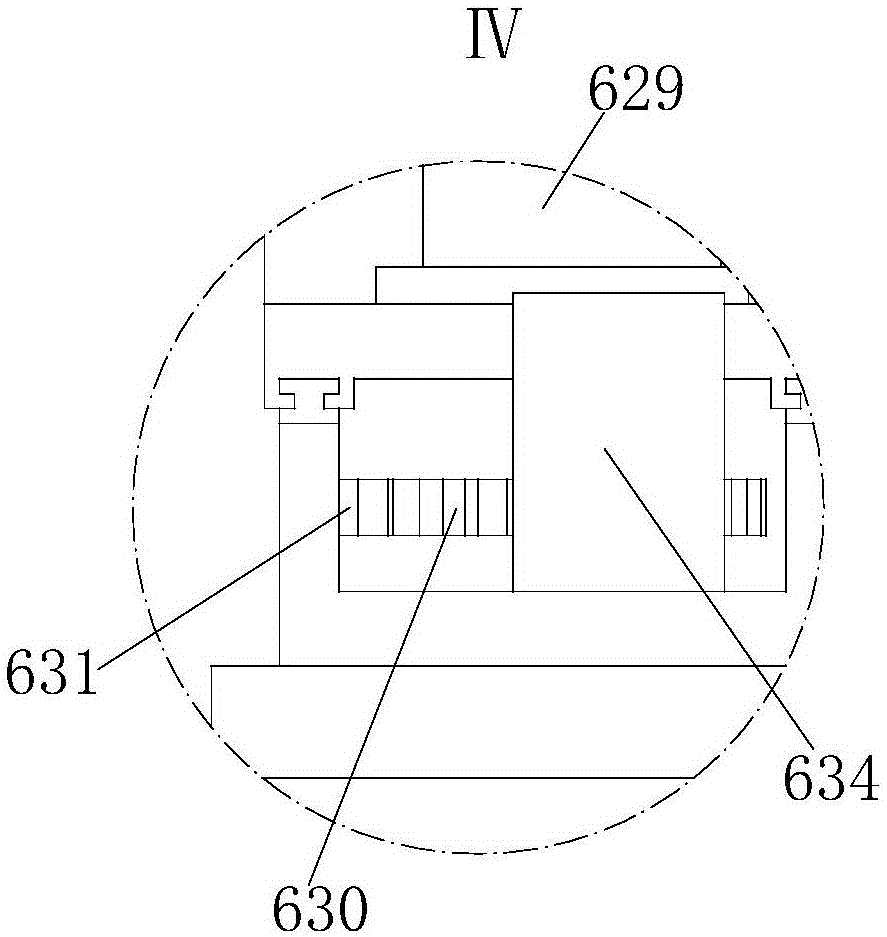

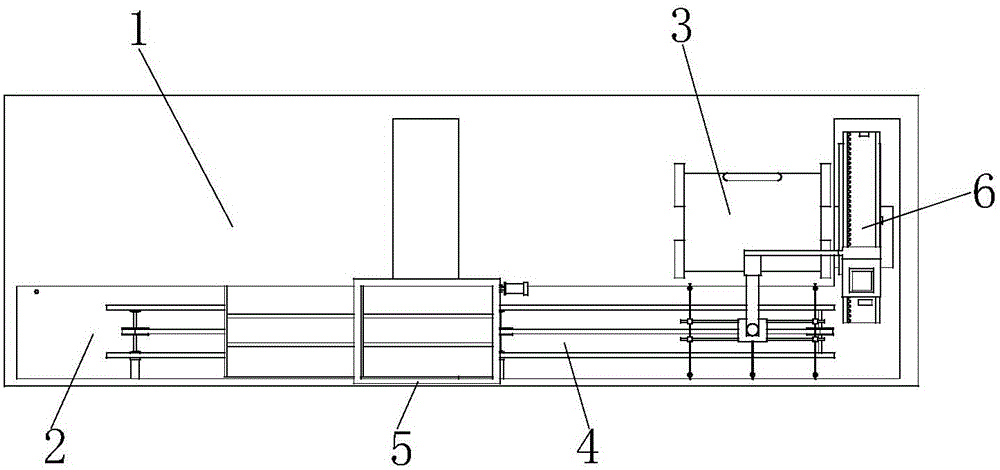

[0035] Such as Figure 1 to Figure 10 As shown, a coal transportation and handling device mainly includes a base 1, an elevated support table 2 and a trolley 3 are provided on the base 1, and a transportation device 4, a feeding device 5 and a handling device 5 are provided on the elevated support table 2. device6. The above is the main structure of the present invention, its main function is to connect the loading box filled with coal at the feeding device 5, then transport it by the transport device 4, and then transport it to the push car by the transport device 6 3.

[0036] The transportation device 4 mainly includes a transportation slide rail 41 installed on the elevated support table 2 and a transportation plate 48 slidably mounted on the transportation slide rail 41, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com