Self-locking weaving-shaft transport vehicle special for spinning

A transporter, self-locking technology, applied in the direction of lifting device, can solve the problems of high handling intensity, difficult to transport weaving shaft, poor safety, etc., and achieve the effect of improving transportation safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

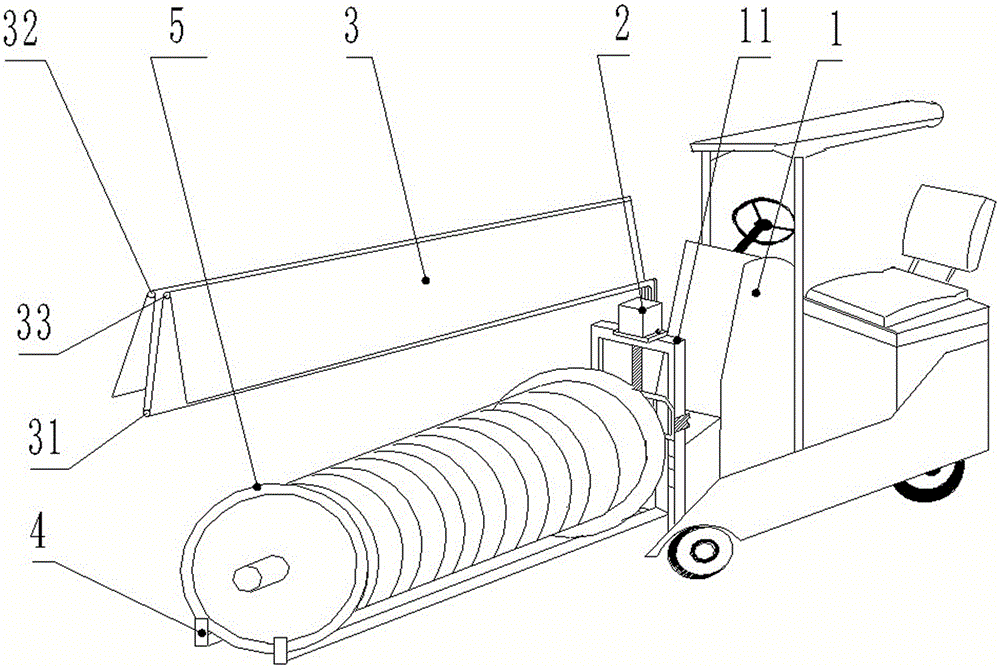

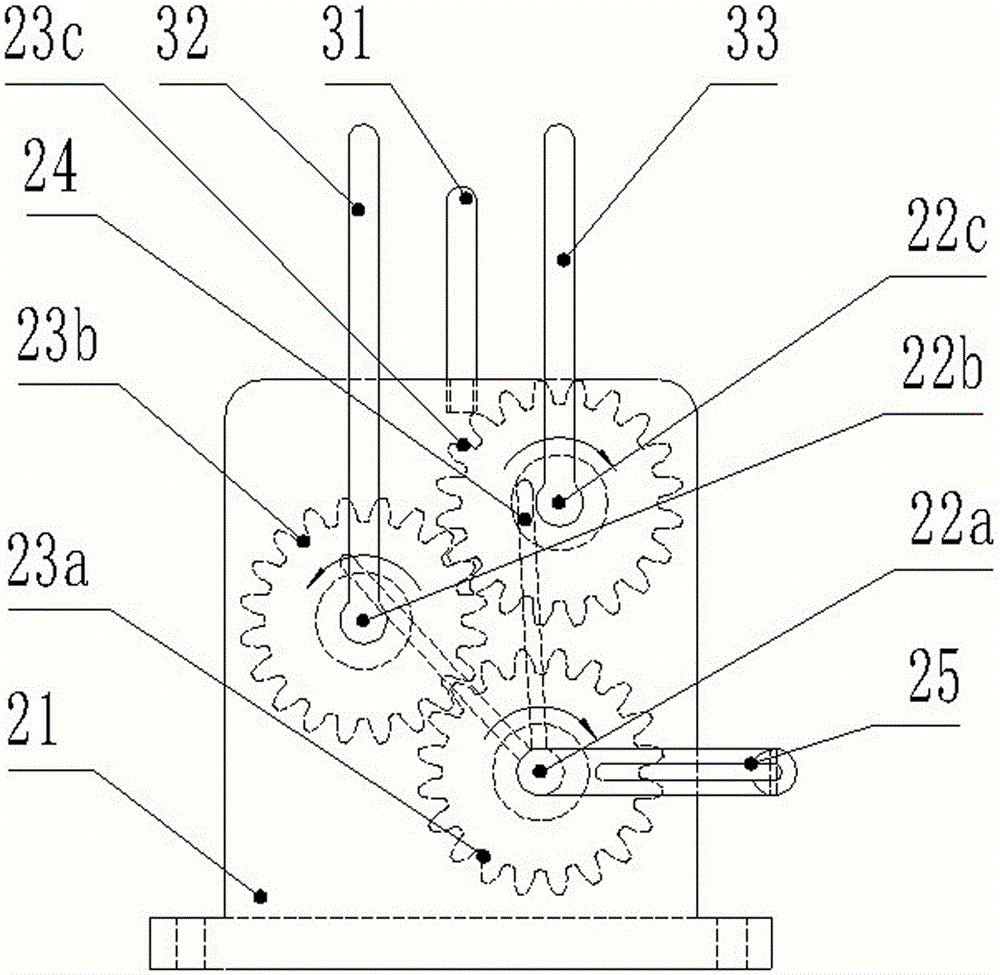

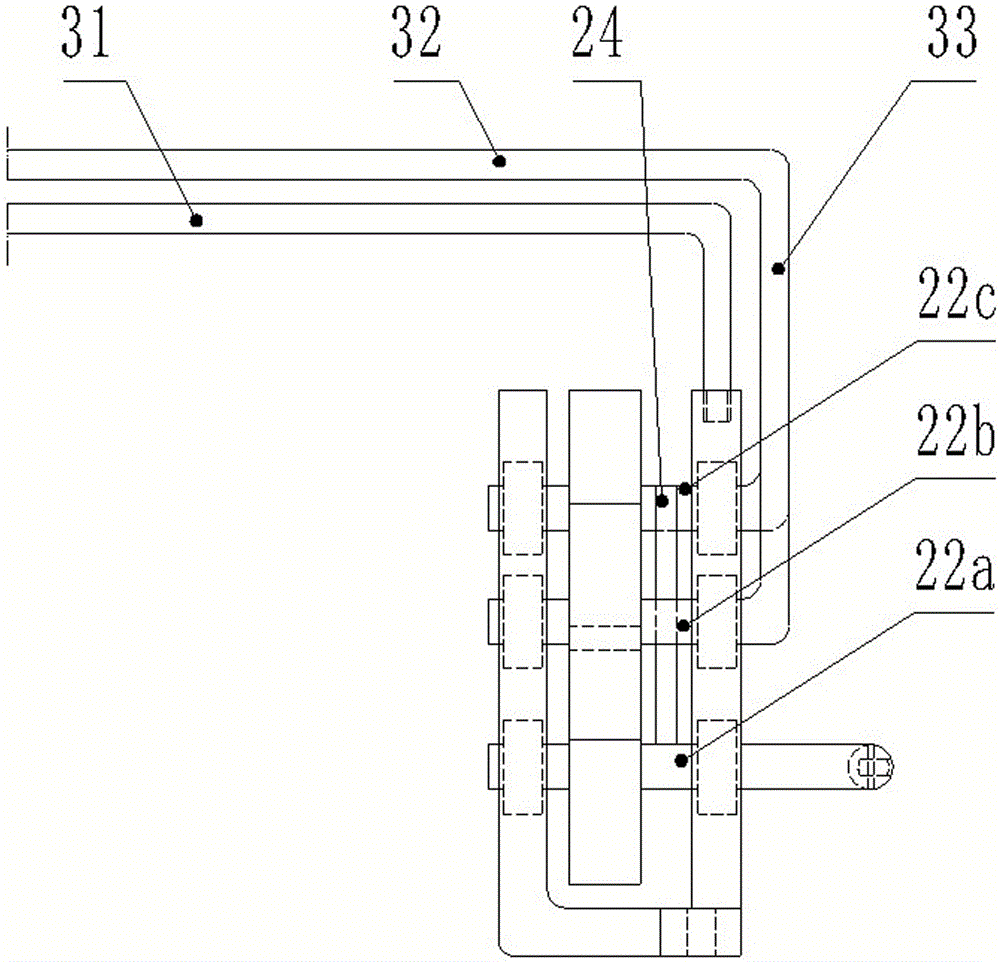

[0017] Such as Figure 1 to Figure 6 It can be seen that the self-locking special weaving shaft transport vehicle for textile of the present invention includes a forklift 1, the front end of the electric forklift 1 is provided with a door frame 11, the upper end of the door frame 11 is provided with a remote control device 2, and also includes a The first bracket 31 in the shape of "¬" above, the remote control device 2 includes a frame 21 in the shape of "凵", on which the first optical axis 22a, the first optical axis 22a, the second The second optical axis 22b, the third optical axis 22c, the middle parts of the first optical axis 22a, the second optical axis 22b, and the third optical axis 22c are respectively provided with a first gear 23a, a second gear 23b, and a third gear 23c, The first gear 23a and the second gear 23b, the second gear 23b and the third gear 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com