Anti-flying spindle rack

A kind of spindle, anti-flying technology, applied in textile and papermaking, weft knitting, knitting and other directions, can solve the problems affecting the environmental sanitation of the workshop, hidden safety hazards in the workshop, and unfavorable health of employees.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention are described in detail below:

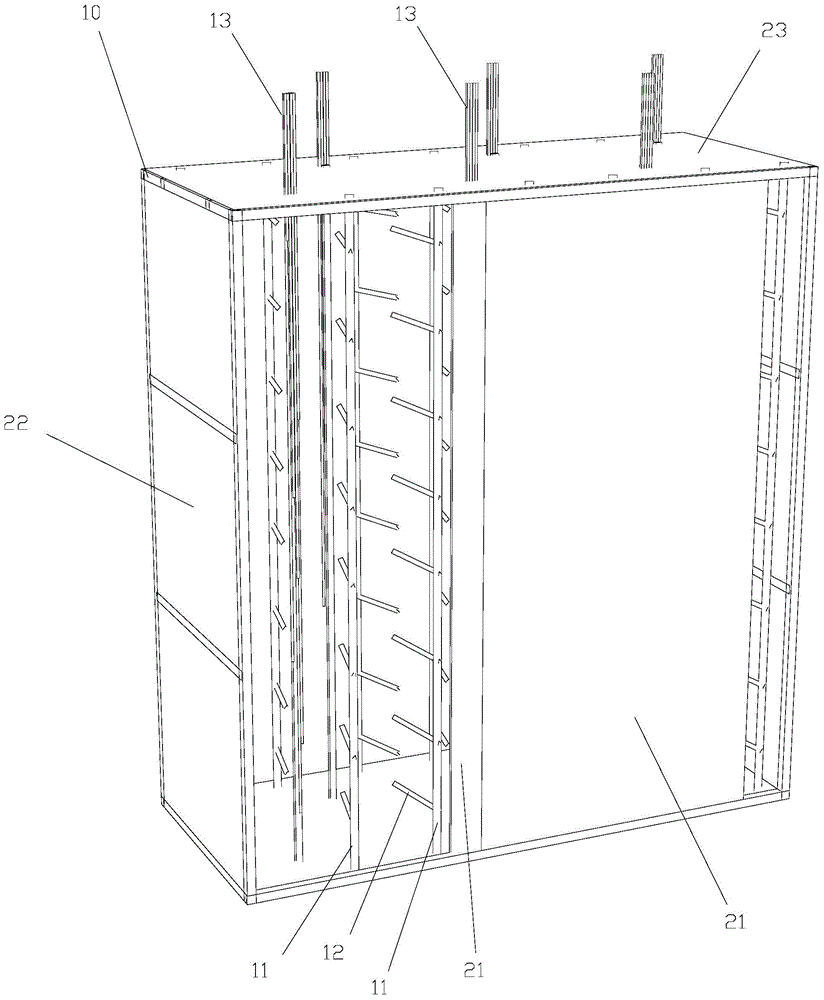

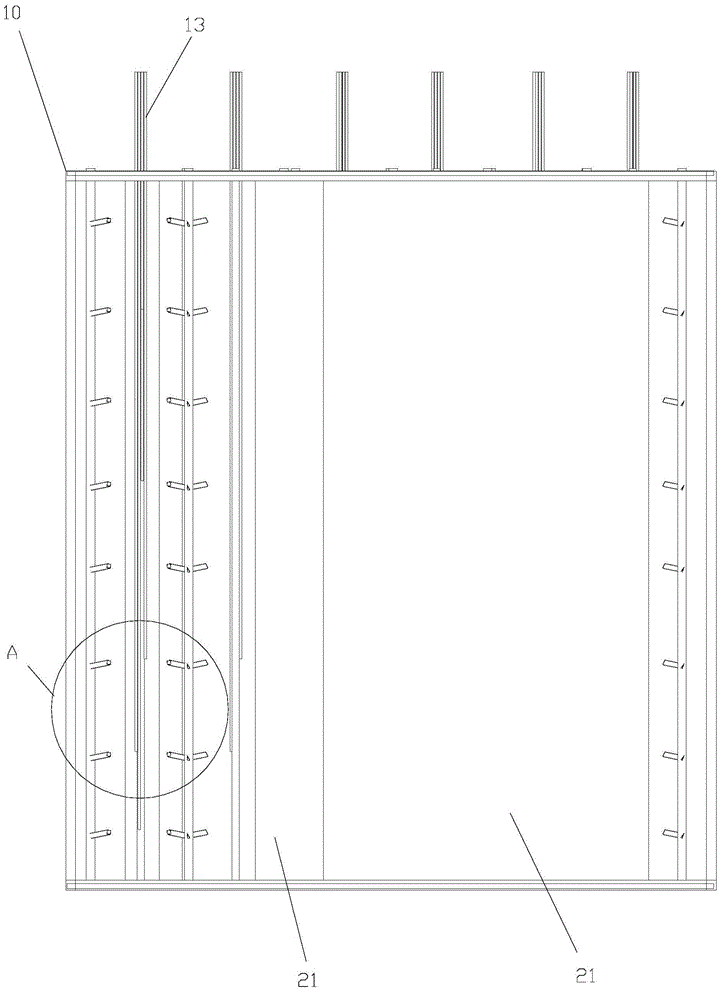

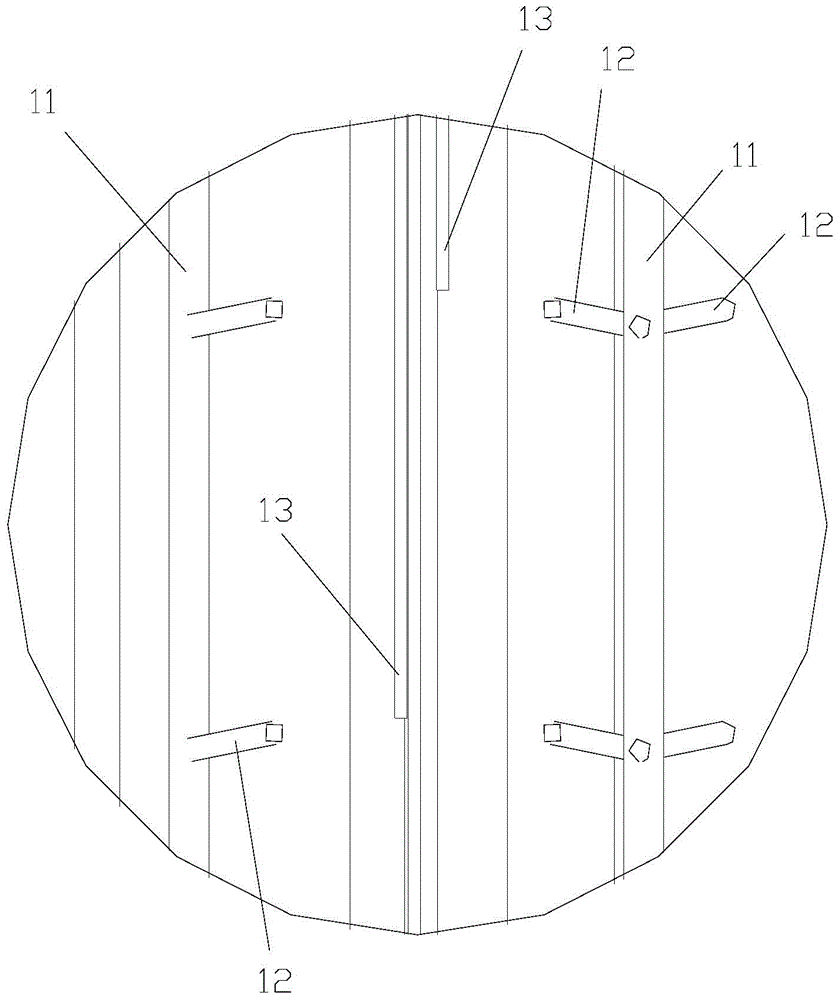

[0021] like Figure 1-3 As shown, it is an anti-flying spindle frame, which includes a main frame 10, a spindle rod 11, a wire tube 13 adapted to the thread on the spindle, and an insulating layer for preventing flying flowers from flying out. The insulating layer is surrounded by the main frame 10, the spindle bar 11 and the guide tube 13 are all arranged in the main frame 10, and the upper port of the guide tube 13 passes through the insulating layer on the top of the main frame 10, and the spindle bar 11 is provided with a pole 12 for placing the spindle, and the guide tube 13 is corresponding to pole 12. Among them, the pole 12 on the spindle rod 11 is used to place the spindle, the guide tube 13 is used to guide the thread on the spindle to the textile operation, and the insulating layer is used to prevent the thread on the spindle from flying when it is drawn out by the textile equipment. Fly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com