Antifreeze shock absorber for railway tracks

A shock-absorbing pad and rail technology, applied in the field of transportation, can solve problems such as weak shock-absorbing effect, increased noise, and short service life of rubber shock-absorbing rings, and achieve the effect of preventing water accumulation and weakening shock-absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

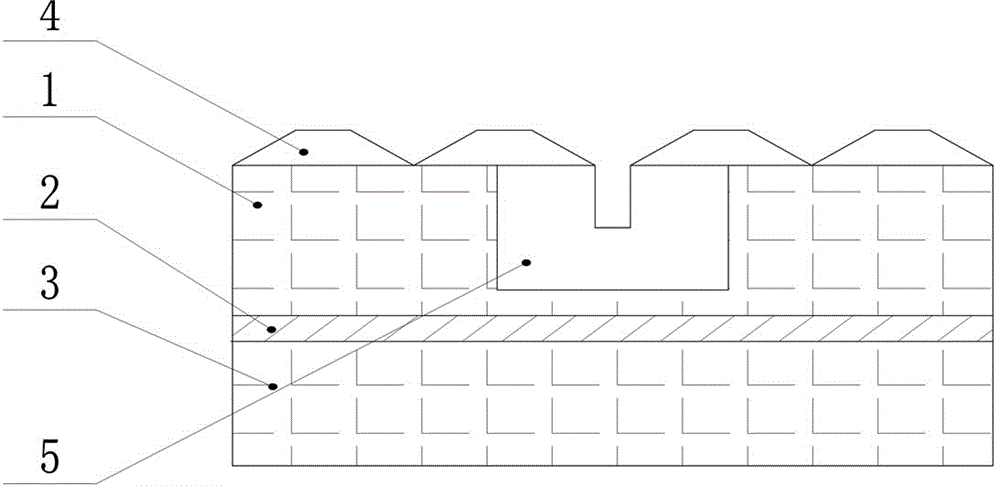

[0011] like figure 1 As shown, a rail antifreeze shock absorber includes a shock absorber body, and the shock absorber is divided into three layers, which are rubber shock absorber layer 1, heat insulation layer 2, and sand and gravel moisture-proof layer 3 from top to bottom; In the middle of the rubber shock-absorbing layer 1, there is a stagnant water compartment 5, and one end of the stagnant water compartment 5 is provided with a drain, and the drain is connected to the outside; the surface of the shock-absorbing pad body is composed of four slopes, and the four slopes face the area Water dark grid 5; the surface of the rubber shock-absorbing layer 1 is provided with a plurality of trapezoidal shock-absorbing cones 4, the bottom of the sand and gravel moisture-proof layer 3 is provided with a moisture-proof pad, and the top of the sand and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com