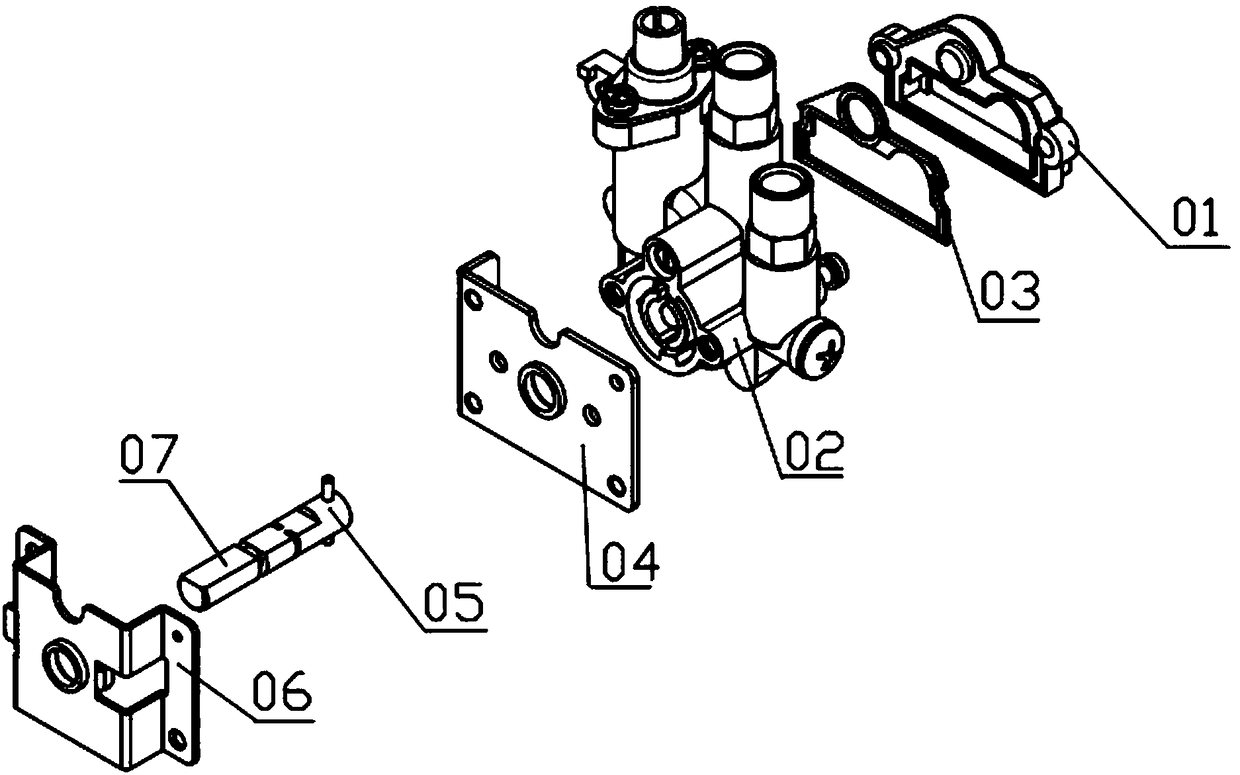

Plug valve assembly of embedded gas stove

A technology for cock valves and gas stoves, applied in the direction of cocks including cut-off devices, valve details, valve devices, etc., can solve problems such as corrosion and rust, and achieve the effects of saving production costs, avoiding safety accidents, and preventing rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention will be further described below with reference to the accompanying drawings and in combination with specific embodiments, so that those skilled in the art can implement it by referring to the description, and the protection scope of the present invention is not limited to the specific embodiments.

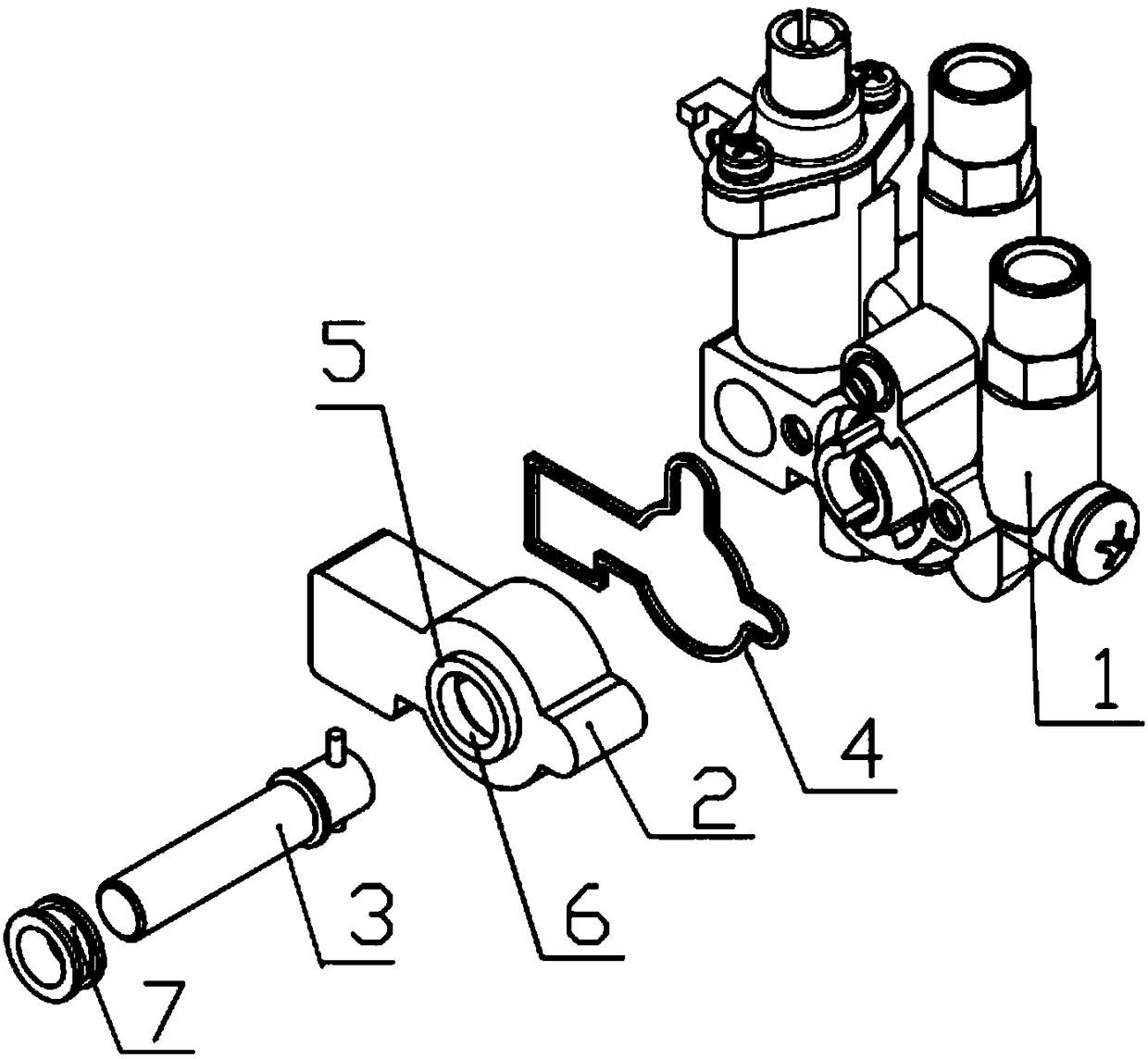

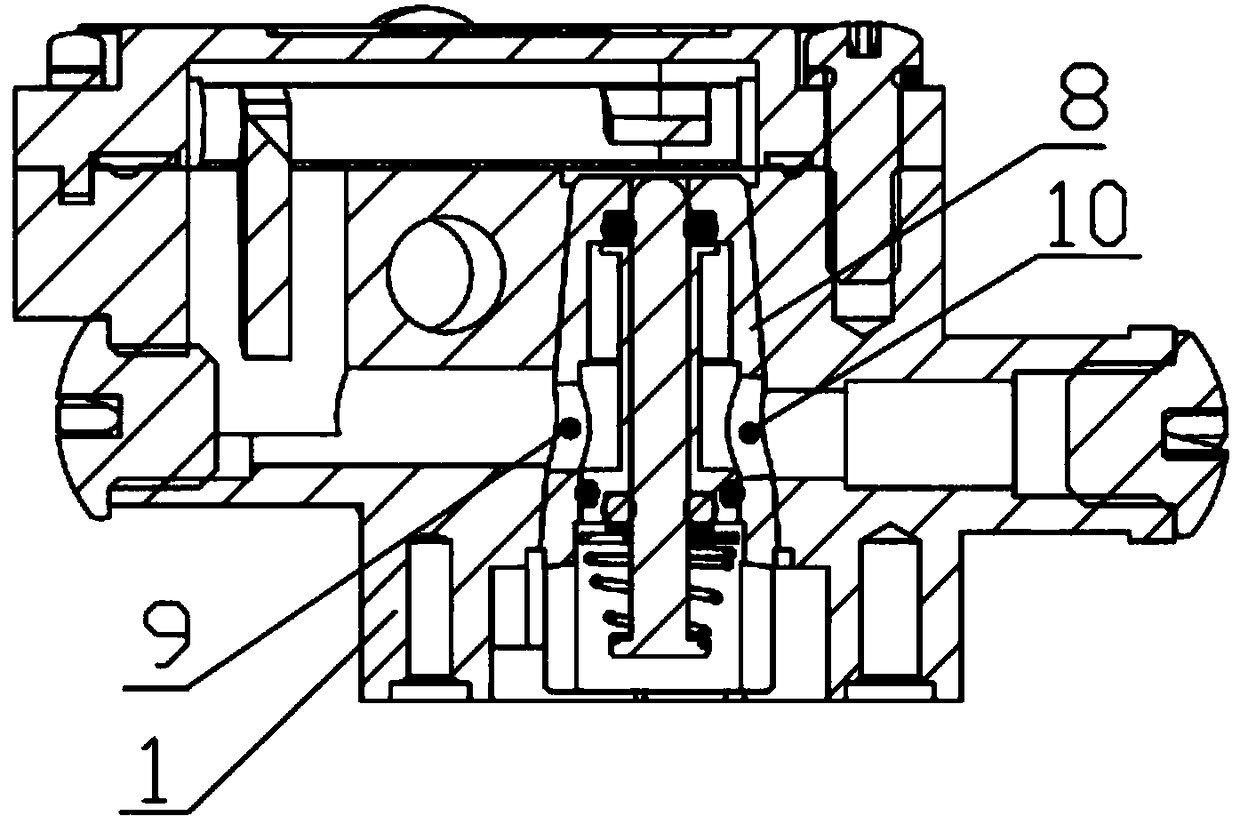

[0015] The invention relates to a plug valve assembly of an embedded gas cooker, such as figure 2 As shown, it includes a valve body 1, a valve cover 2 covered on the valve body 1, a cylindrical knob rod 3, and a seal 4 arranged between the valve cover 2 and the valve body 1, and the seal 4 is embedded in the valve body. On the inner side wall of the cover 2 , the valve cover 2 is provided with a through hole 5 through which the knob rod 3 passes, and the through hole 4 includes a fitting ring surface 6 formed between the knob rod 3 . With this structure, the knob rod 07 with milling edge 09 is replaced with a pure cylindrical knob rod 3. On this basis, the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com