Riveting structure, riveting die, riveting process and air conditioner

A riveting structure and riveting technology, applied in the directions of rivets, forming tools, manufacturing tools, etc., can solve the problems of small separation force between bolts and sheet metal parts, failure to meet mechanical performance requirements, and damage to the surface layer of sheet metal parts. Wide range, easy installation, high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

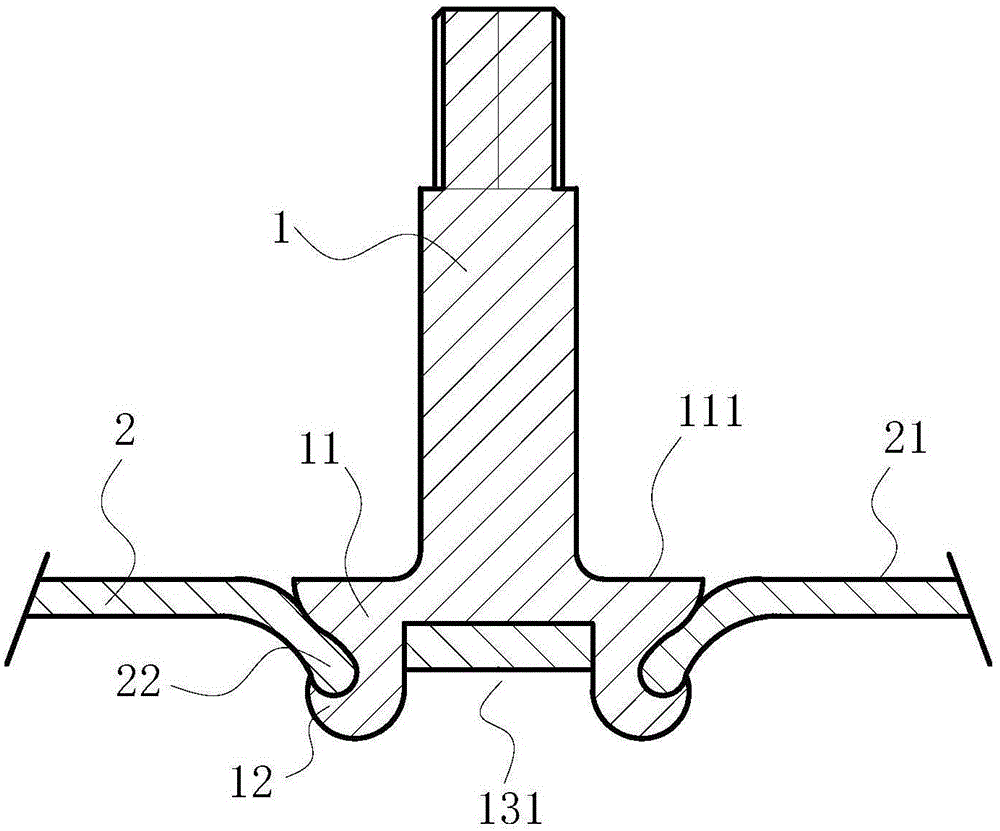

[0039] This preferred embodiment provides a riveting structure. Such as figure 1 As shown, the bolt 1 and the support member 2 are included, and the outer surface 111 of the flange 11 of the bolt 1 is adjacent to the surface 21 of the support member 2 and is in the same plane.

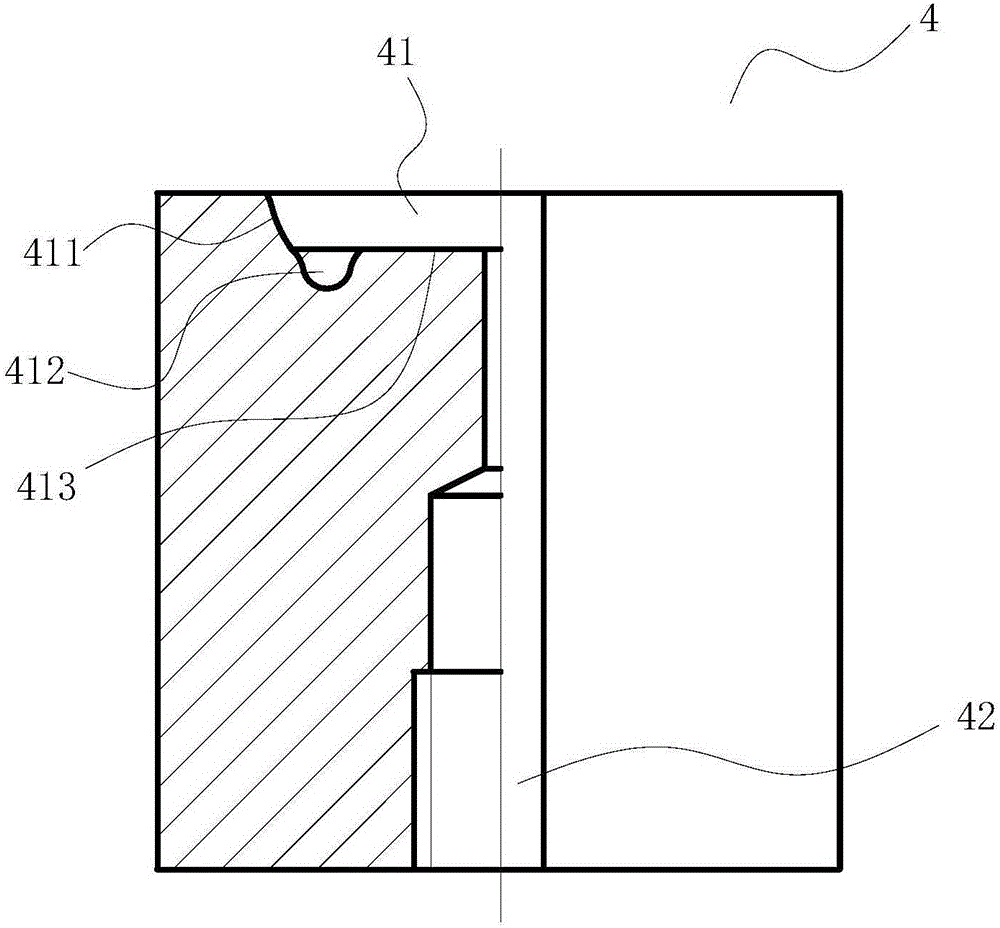

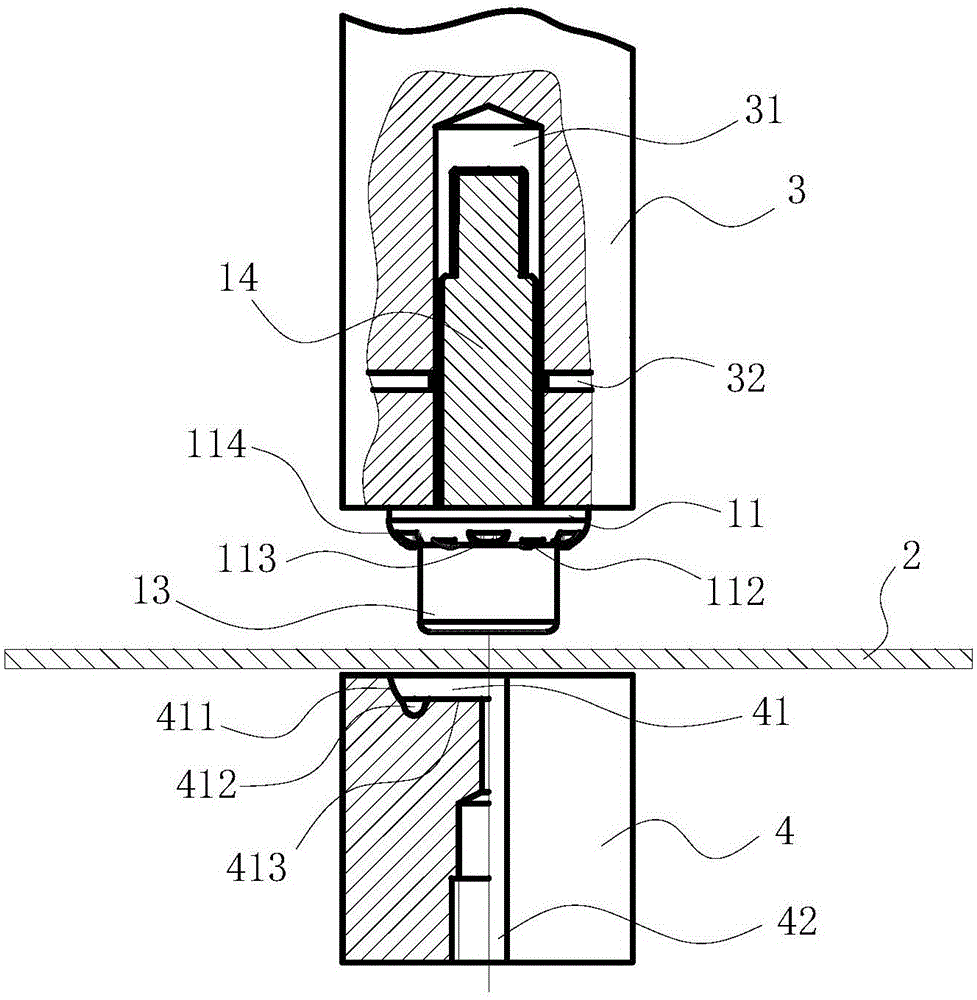

[0040] Such as figure 2 and image 3 As shown, the riveting die used to form the riveting structure includes an upper die 3 and a lower die 4, and the upper die 3 is provided with a cavity 31 for accommodating the screw 14 and a set screw 32 for fixing the screw 14; the lower die 4 A concave molding cavity 41 is formed at the end of the upper body, and the molding cavity 41 is surrounded by a rib 411 , a groove 412 and a bottom surface 413; The lower mold 4 is provided with a residual oil recovery hole 42 for recovering the lubricating oil between the mold and the plate of the support member 2 .

[0041] The riveting process of using the riveting mold to form the riveting structure includes the fo...

Embodiment 2

[0053] This preferred embodiment provides a riveting structure whose structure, processing mold and processing technology are basically the same as those of the preferred embodiment 1. The riveted structure includes a bolt and a support, and the outer side of the flange of the bolt is close to the surface of the support and is in the same plane.

[0054]The difference is that the specific structure of the flange is not limited, whether the bolts form flanging, and the specific shape of the flanging are not limited, as long as the firmness of the riveted structure can be ensured.

Embodiment 3

[0056] This preferred embodiment provides an air conditioner. The air conditioner includes the riveting structure described in the preferred embodiment one or two, which realizes the use of galvanized sheets, galvanized sheets, and galvanized aluminum-magnesium steel sheets (mainly galvanized aluminum-magnesium-coated steel sheets less than or equal to 2mm free of spraying) in the air conditioner. For the application on the chassis, the bolts of the air-conditioning chassis compressor can be riveted and formed at one time, without the need for subsequent spraying treatment, which is energy-saving and environmentally friendly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com