Diesel engine transmission gear

A technology for transmission gears and diesel engines, which is applied to transmission parts, gear lubrication/cooling, belts/chains/gears, etc. It can solve the problems of high failure rate of intermediate gears, gear axial clearance deviation, bearing failures, etc., to improve gears The effect of lubrication, adding axial positioning measures, and solving the problem of faulty inertial mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

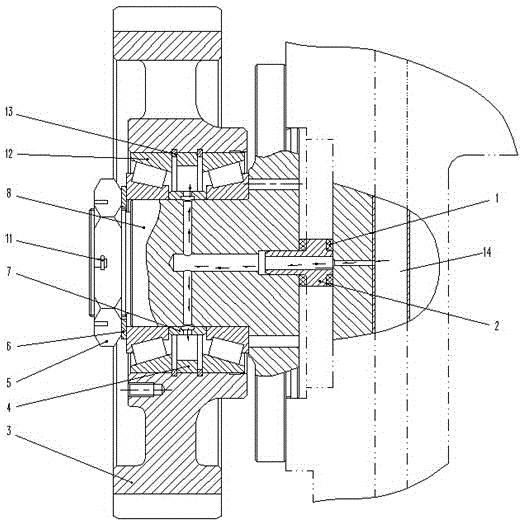

[0018] Such as figure 1 It is a structural schematic diagram of the present invention, a transmission gear of a diesel engine, including an intermediate gear 3 and an intermediate bracket 8, the intermediate gear 3 is fastened on the intermediate bracket 8 through a nut 5 and a washer 2 6, and the connection between the intermediate bracket 8 and the side of the intermediate gear 3 , spacer 1 7, spacer 2 4 are provided, spacer 1 7, spacer 2 4 are set face to face, spacer 1 7 is set on the middle bracket, spacer 2 4 is frozen in the inner hole of the intermediate gear 3, and needs to be used Liquid nitrogen freezer assembly. Back-up ring 13 is sleeved on spacer ring two 4 ends, and rolling bearing 12 is sleeved on the outer side. Gasket 2 6 can adopt part numbers of different thicknesses.

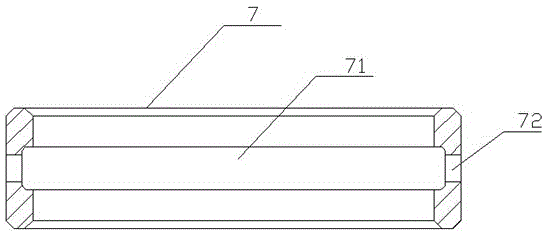

[0019] Such as figure 2 As shown, spacer ring one 7 is annular, and the inner diameter place has oil groove 71, has two oil outlet apertures 72 on the oil groove.

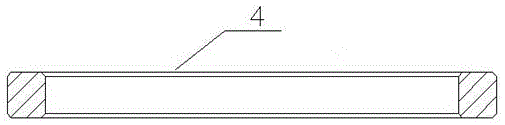

[0020] Such as ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com