hub unit

A hub unit and hub technology, used in engine components, engine sealing, engine lubrication, etc., can solve the problems of limited oil sealing effect of outer oil seal, inability to replenish oil film in time, failure of outer oil seal, etc., to improve the use environment and function. The effect of improving the lifespan and improving the functional lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

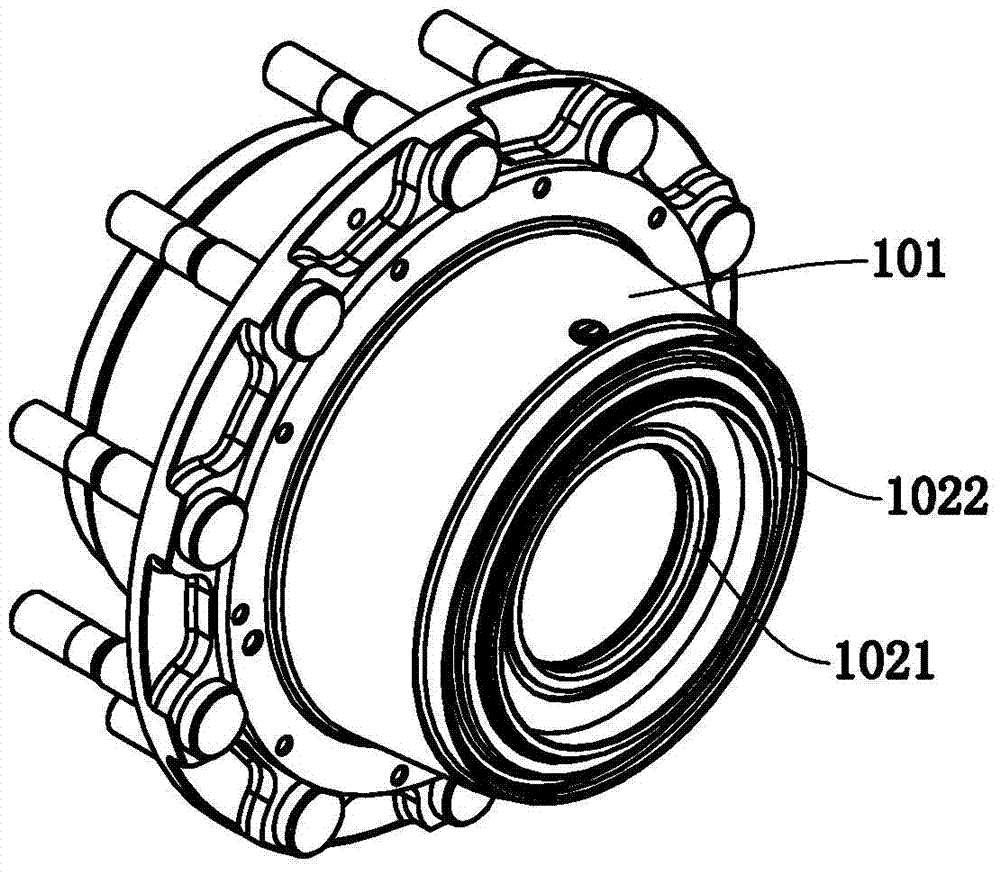

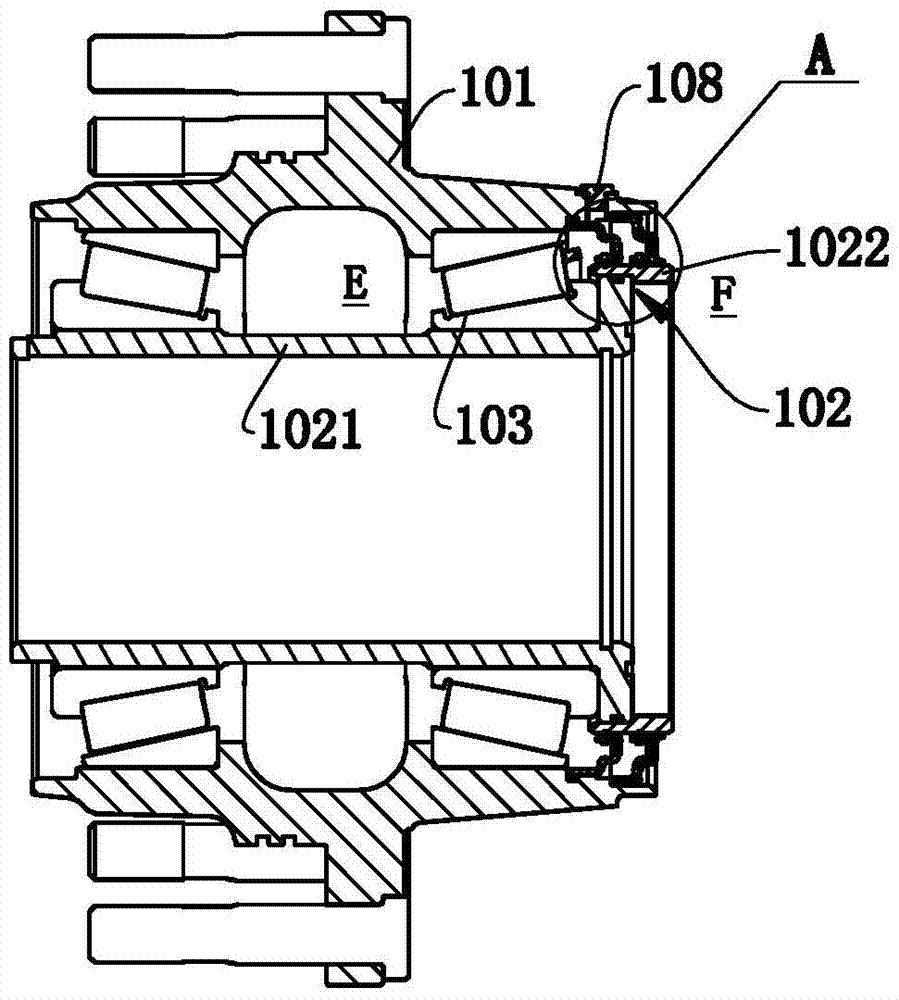

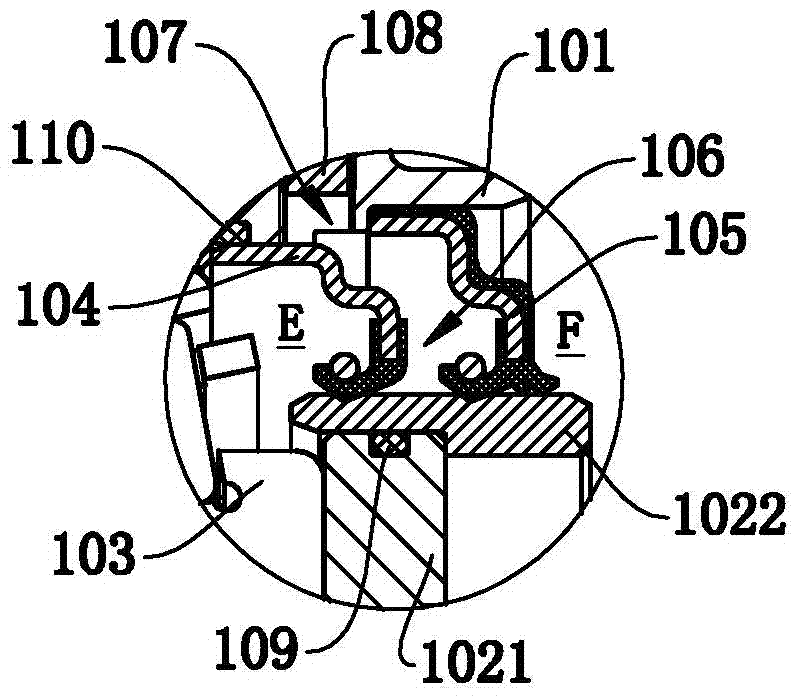

[0024] like Figure 1 to Figure 3 Commonly shown, a hub unit, the shaft sleeve 102 runs through the hub body 101, and is installed on the hub body 101 through the bearing 103, and a first sealing ring 104 is provided between the sealing surface of the hub body 101 and the sealing surface of the shaft sleeve 102 and the second sealing ring 105 , along the axial direction, the inner side of the first sealing ring 104 is the sealing area E, and the outer side of the second sealing ring 105 is the atmospheric area F.

[0025] An oil storage cavity 106 is formed between the sealing surface of the hub body 101, the sealing surface of the shaft sleeve 102, and the first sealing ring 104 and the second sealing ring 105, and the hub body 101 is provided with an oil filling hole for filling the oil storage cavity 106 107, the oil injection hole 107 is provided with a screw plug 108.

[0026] Due to the design of an independent oil storage chamber 106, special lubricating oil for sealin...

Embodiment 2

[0033] like Figure 4 to Figure 6 Commonly shown, a hub unit, the shaft sleeve 202 runs through the hub body 201, and is installed on the hub body 201 through the bearing 203, and a first sealing ring 204 is provided between the sealing surface of the hub body 201 and the sealing surface of the shaft sleeve 202 and the second sealing ring 205 , along the axial direction, the inner side of the first sealing ring 204 is the sealing area E, and the outer side of the second sealing ring 205 is the atmospheric area F.

[0034] An oil storage cavity 206 is formed between the sealing surface of the hub body 201, the sealing surface of the shaft sleeve 202, and the first sealing ring 204 and the second sealing ring 205, and the hub body 201 is provided with an oil filling hole for filling the oil storage cavity 206 207, the oil injection hole 207 is provided with a screw plug 208.

[0035] In this embodiment, lubricating oil is injected into the oil storage chamber 206 from the oil i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com