A pile flushing hose assembly for conveying high-pressure seawater used in a pile flushing system of a jack-up drilling platform and a preparation method thereof

A drilling platform and hose assembly technology, applied in the direction of hoses, pipes, applications, etc., can solve the problems of pipe weight, large bending radius, unreasonable structural design, etc., to improve physical and mechanical properties, good sealing and bearing The effect of pressure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

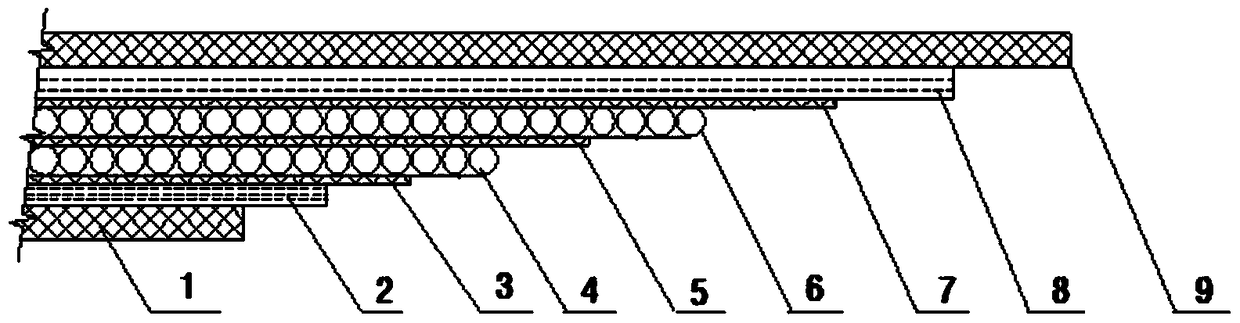

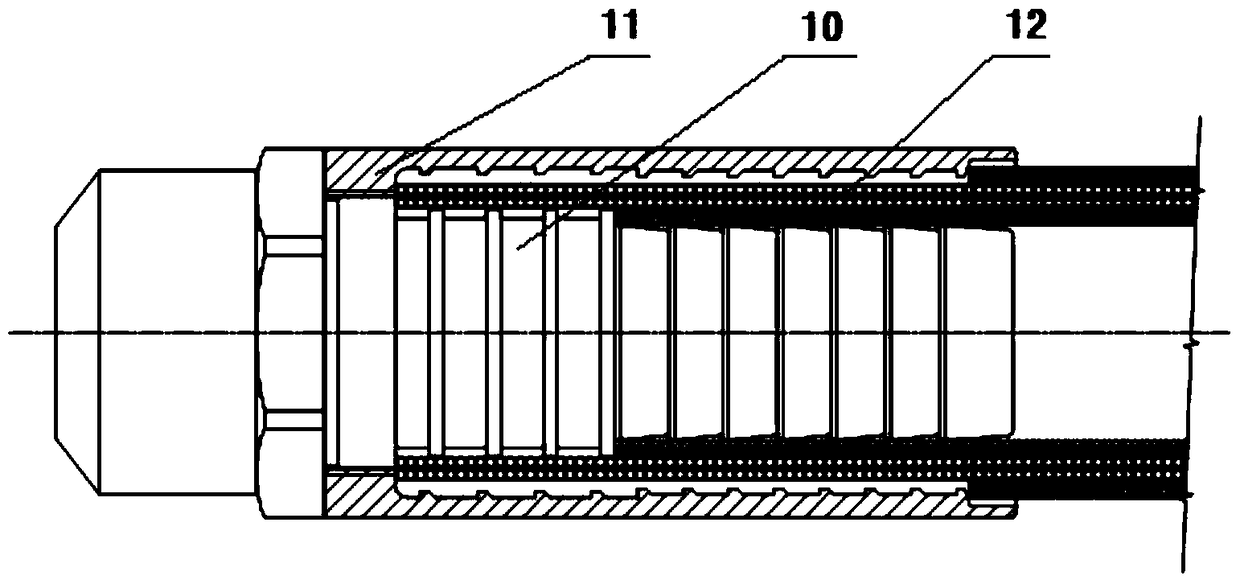

[0028] like figure 1 As shown, a pile flushing hose assembly for conveying high-pressure seawater in the pile flushing system of the self-elevating drilling platform of the present invention, the hose is sequentially composed of the inner film 1, the buffer tape layer 2, the second One layer of medium rubber layer 3, the first layer of steel wire rope 4, the second layer of medium rubber layer 5, the second layer of steel wire rope 6, the third layer of medium rubber layer 7, the outer protective tape layer 8 and the outer layer of film 9; wherein, the first The rubber layer 3 in the middle layer, the steel wire rope 4 in the first layer, the rubber layer 5 in the second layer, the steel wire rope 6 in the second layer and the rubber layer 7 in the third layer together form a pressure-bearing skeleton structure.

[0029] The inner film is made of nitrile rubber with an acrylonitrile content of 40%. It is made by adding neoprene, carbon black and petroleum resin in a mass ratio...

Embodiment 2

[0034] The glue used in each glue layer of the hose is the same as in Example 1.

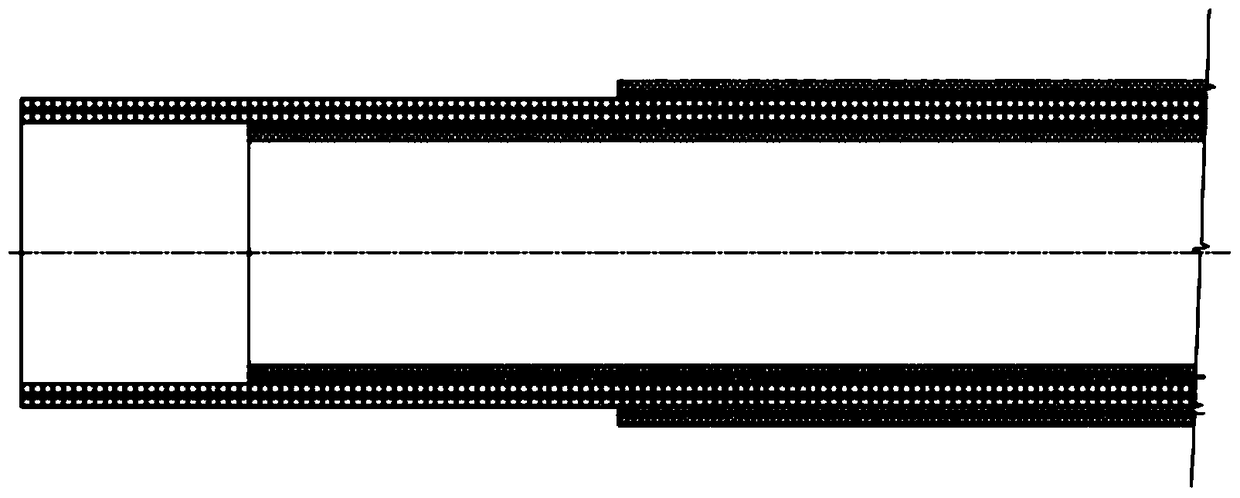

[0035] When making a hose, the mandrel is used as a support for winding the hose on it. Before preparing the hose, the mandrel must be cleaned; prepare Leruigu 1808 release agent, and stir the release agent evenly until It is a milky white liquid. Coat a layer of prepared Leruigu 1808 release agent on the mandrel. The function of the release agent is to take the mandrel out of the rubber tube smoothly after the rubber tube is prepared and shaped; Wrap the inner layer film on the outer surface, the winding should be smooth without wrinkles, and the winding should be seamless, and multiple mandrels can be used for preparation at the same time; the buffer tape layer is wound on the outside of the first inner layer film, and the buffer tape layer can be high-strength fiber For cord fabric, the buffer tape layer is wrapped at 45 degrees relative to the longitudinal axis of the mandrel, with a lap sea...

Embodiment 3

[0038] The glue used in each glue layer of the hose is the same as in Example 1.

[0039] When making hoses, mandrels are used as supports for winding rubber hoses on them. Before making hoses, the mandrels must be cleaned; prepare Leruigu 1808 release agent, and stir the release agent evenly until it becomes Milky white liquid, apply a layer of prepared Leruigu 1808 release agent on the mandrel, the function of the release agent is to take the mandrel out of the hose smoothly after the hose is prepared and shaped; on the outside of the mandrel Wrap the inner layer of film on the surface, the winding should be smooth and free of wrinkles, and the winding should be seamless. Multiple mandrels can be used for preparation at the same time; the buffer tape layer is wound on the outside of the first inner film, and the buffer tape layer can be high-strength fiber cord , the buffer tape layer is wrapped at 45 degrees relative to the longitudinal axis of the mandrel, and the lap seam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com