C-column corner reinforcing plate testing device for automobile

A technology for reinforcing plates and inspection tools, which is applied to measuring devices, instruments, and mechanical devices, etc., can solve the problems of inconvenient maintenance of inspection tools, cumbersome processing technology, and heavy handling of inspection tools, so as to improve market competitiveness and simplify processing. The effect of shortening the process and development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

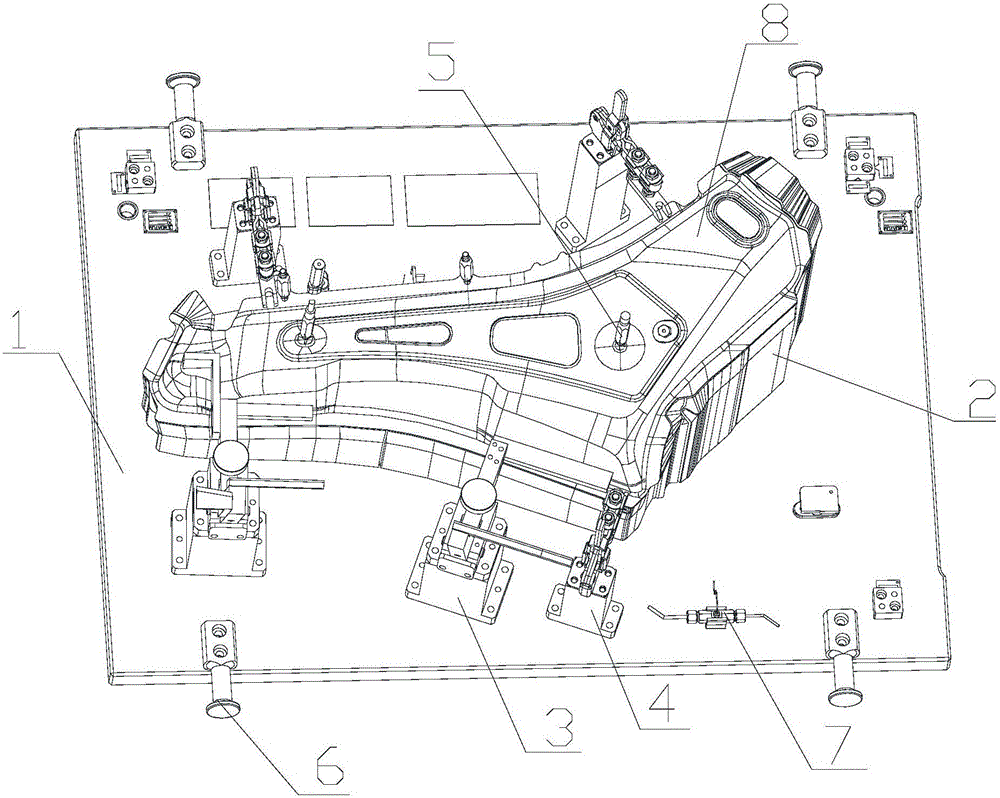

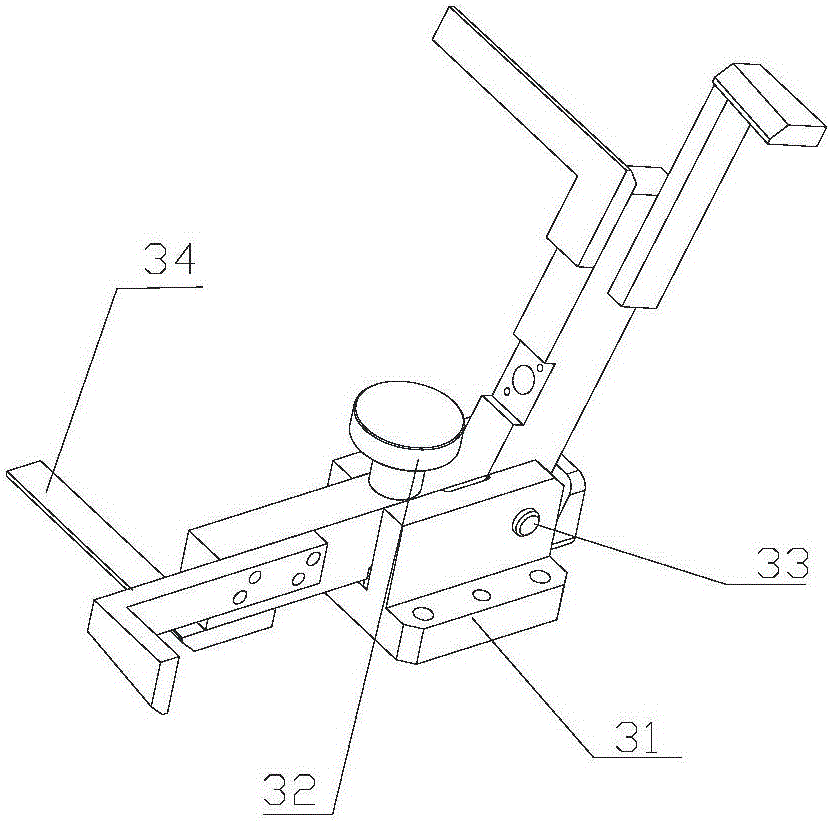

[0026] Such as figure 1 As shown, this embodiment provides an automobile C-pillar corner reinforcement plate inspection tool, which is installed on a machine tool, and includes a mounting base 1 and a testing tool body 2 arranged on the mounting seat 1. The profile of the testing tool body 2 is consistent with the standard C The profile of the reinforcement plate at the corner of the column is the same. The mounting base 1 is provided with a clamping plate 3 and a clamping piece 4 for fixing the workpiece 8 to be tested on the inspection tool body 2. The inspection tool body 2 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com