Metallographic cold-inlaying device capable of adjusting inlaying position and angle of sample

An angle and sample technology, applied in the preparation of test samples, etc., can solve the problems that the position of the sheet sample cannot be adjusted, and the relative position and angle of the sample cannot be changed freely, so as to reduce the detection cost, avoid secondary pollution, clamping handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

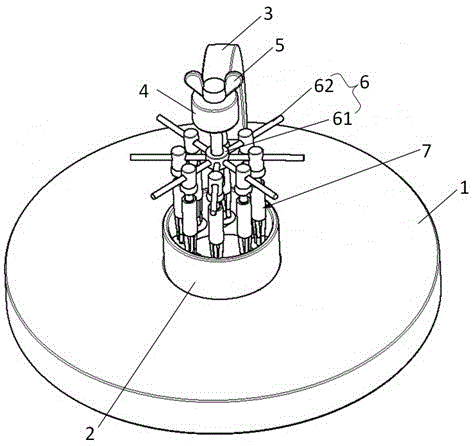

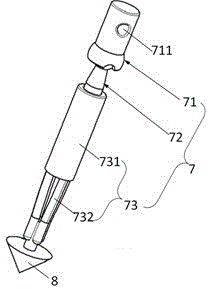

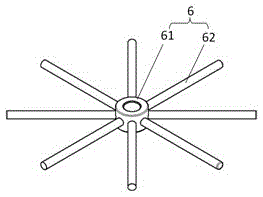

[0037] Such as Figure 1~3 , 7, a metallographic cold mounting device with adjustable sample mounting position and angle, including a base 1, a hollow bowl-shaped sample mounting mold 2 is installed in the middle of the upper top surface of the base 1, and the upper top surface edge is installed There is an inverted L-shaped column 3, the front end of the upper part of the column 3 is connected to the hollow cylindrical fixed sleeve 4, the butterfly connecting nail 5 passes through the fixed sleeve 4, and its lower end is threaded with the bracket 6; the bracket 6 is connected by the connecting sleeve 61 and eight The cross-section welded on the outer wall of the sleeve 61 is composed of circular support rods 62. The support rods 62 are evenly distributed along the outer circumferential wall of the connecting sleeve 61. Each support rod 62 is equipped with a ball-twisted telescopic claw 7, and the ball-twisted telescopic claw 7 moves radially on the pole 62, and the lower end ...

Embodiment 2

[0044] Such as Figure 4~6 , 7, a metallographic cold mounting device with adjustable sample mounting position and angle, including a base 1, a hollow bowl-shaped sample mounting mold 2 is installed in the middle of the upper top surface of the base 1, and the upper top surface edge is installed There is an inverted L-shaped column 3, the front end of the upper part of the column 3 is connected to the hollow cylindrical fixed sleeve 4, the butterfly connecting nail 5 passes through the fixed sleeve 4, and its lower end is threaded with the bracket 6; the bracket 6 is connected by a connecting sleeve 61 and two The outer wall of the cover 61 is welded to the cross-sectional square pole 62, which is evenly distributed along the outer wall of the connecting sleeve 61. Each pole 62 is equipped with a ball-twisted telescopic claw 7, and the ball-twisted telescopic claw 7 is in the The pole 62 moves radially, and the lower end of the telescopic jaw 7 of the ball twist is placed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com