Method for analysis of tobacco leaf quality change trend in lamina controlled atmosphere storage process

A quality change and trend analysis technology, applied in the field of tobacco analysis, can solve problems such as correlation, complexity of data statistical analysis, and non-independence of data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

[0043] 1. Materials and methods

[0044] 1.1 Test material

[0045] In 2009, Guizhou Dafang C3F, Yunnan Dali B2F, Yunnan Ning'er B2F, Hunan Chenzhou C3F, Shandong Rizhao B2F and other 5 grades of recured sheet tobacco.

[0046] 1.2 Method

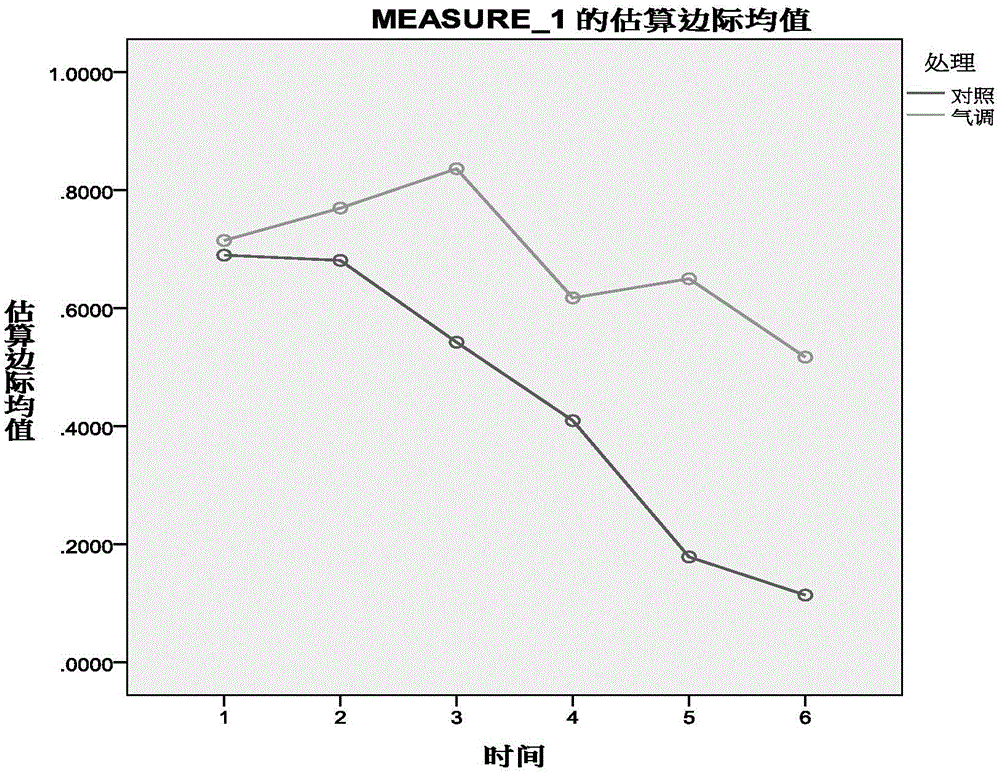

[0047] 1.2.1 Experimental design

[0048] Set up 6 groups of modified atmosphere treatment stack groups and 6 groups of conventional storage stack groups, and the conventional storage stack group is the control group; each test sample in each group is 2 boxes, and 12 groups are collectively stacked in Huaiyin, Jiangsu China Tobacco The same test site in No. 1 warehouse of Xuyang Tobacco Leaf Warehouse in Cigarette Factory. Beginning in August 2011, the original data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com