Current measuring method and device

A current measurement and current technology, applied in measurement devices, measurement of electrical variables, measurement of current/voltage, etc., can solve problems such as zero point drift, limiting product measurement accuracy, and output zero point stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

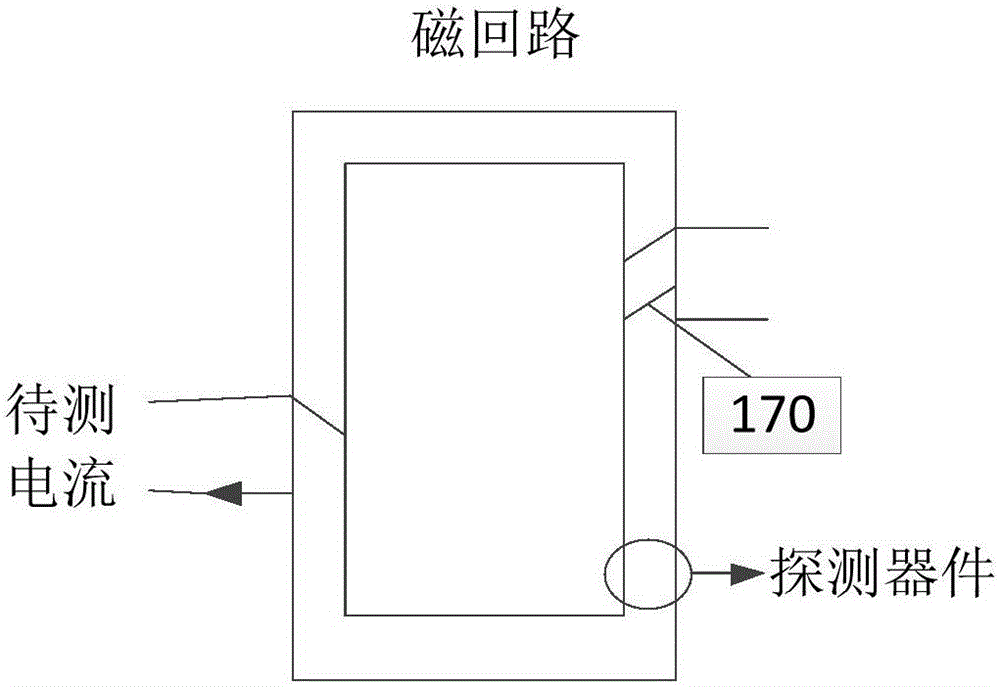

[0052] The existing measurement technology is prone to the stability of the output zero point due to the characteristics of magnetic materials and circuit characteristics, that is, the problem of "zero point drift", which affects the measurement accuracy.

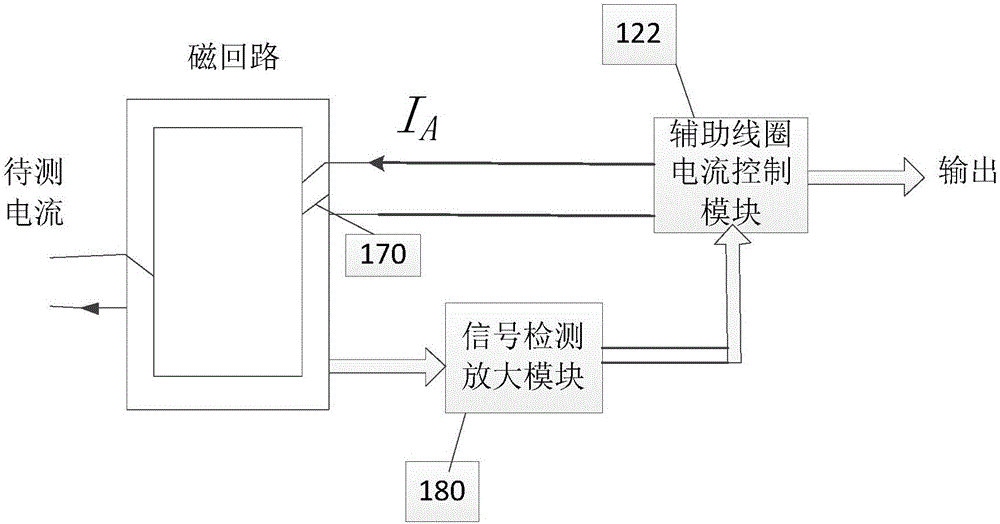

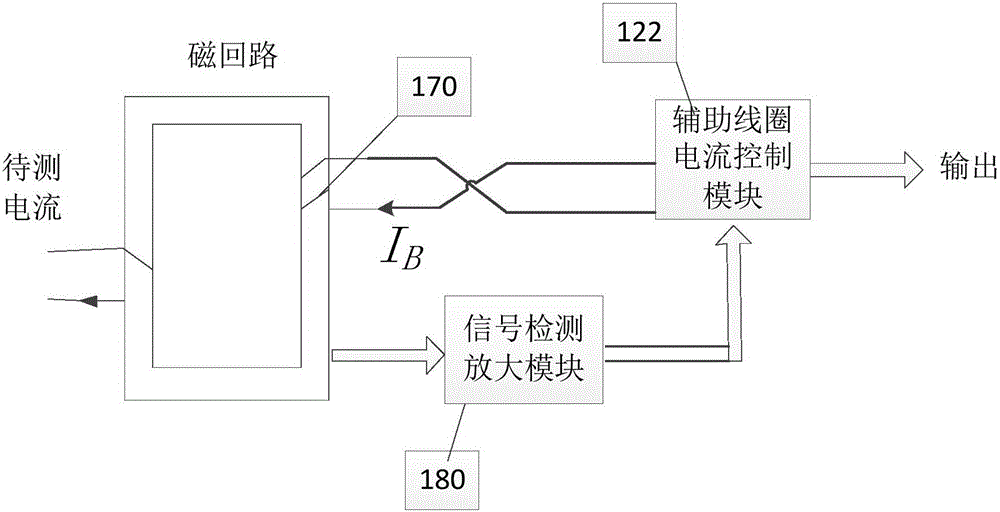

[0053] In view of the above situation, after long-term research and a lot of practice, the researchers provided a current measurement method. On the basis of the existing detection method, it was proposed that by changing the direction of the magnetic field generated by the current in the auxiliary coil in the magnetic circuit, A method for realizing the current signal to be measured in the form of a differential component. Compared with the prior art, the method can greatly reduce the zero point drift of the detection result and improve the measurement accuracy.

[0054] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com