A method and device for measuring touch response time of capacitive touch screen

A capacitive touch screen and response time technology, applied in the field of capacitive touch screen touch response time measurement, measuring capacitive touch screen touch response time, can solve the problems of high precision, low precision, high cost, etc., and achieve good repeatability and price. Inexpensive and easy to measure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

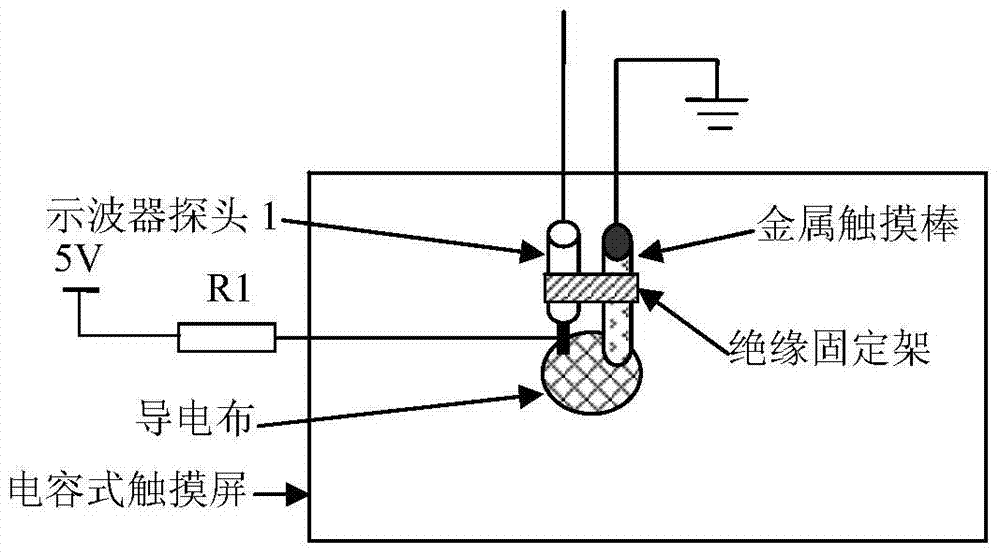

[0045] see figure 1 .

[0046]A device for measuring the touch response time of a capacitive touch screen, consisting of a piece of conductive cloth or other conductive metal film attached to the touch surface of the touch screen, a metal touch rod, a resistor R1, a ground wire of the metal touch rod, and a first measuring probe (such as an oscilloscope probe 1 ), a second measurement probe (such as oscilloscope probe 2), an insulating fixture and a signal acquisition device (such as an oscilloscope). The value of resistor R1 is generally 5kΩ, and can also be other resistance values between 1kΩ and 100kΩ. One end of resistor R1 is connected to the detection end of oscilloscope probe 1, and the other end is connected to a 5V power supply, which can also be a 3.3V, 2.8V power supply, and are not limited to these supply voltages. The metal touch rod is grounded through the ground wire, and fixed together with the oscilloscope probe 1 through the insulating bracket. The test e...

Embodiment 2

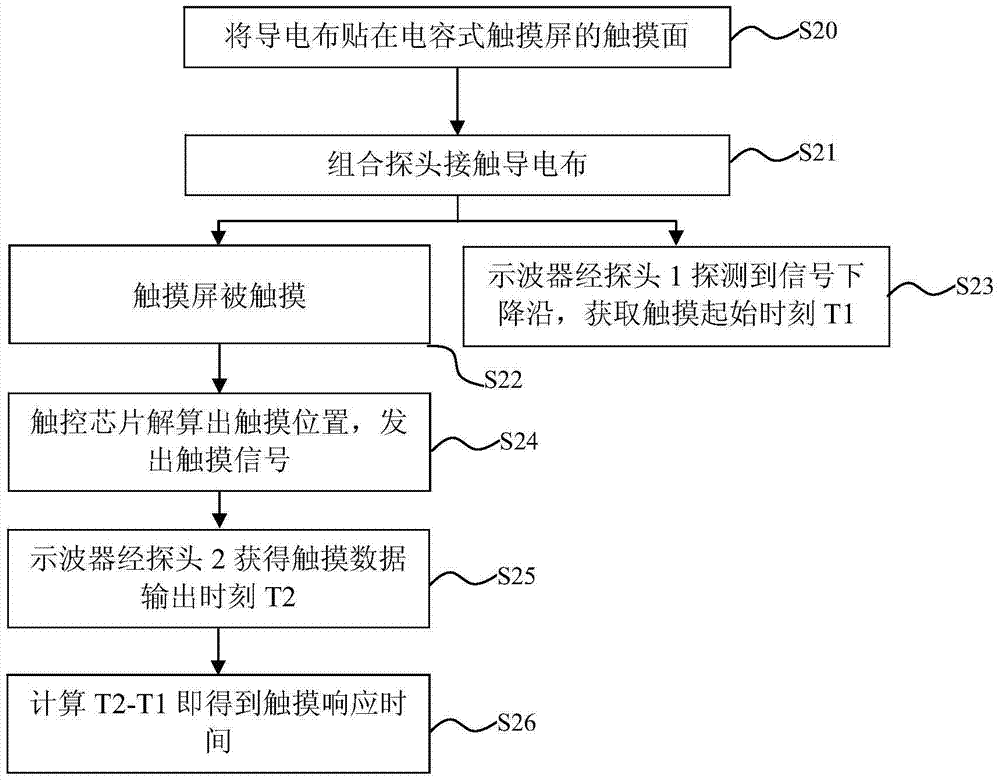

[0048] Such as figure 2 , image 3 , Figure 4 with Figure 5 .

[0049] A method for measuring the touch response time of a capacitive touch screen, it comprises the following steps:

[0050] Step 20, first, paste the conductive cloth on the touch surface of the capacitive touch screen. The conductive cloth is a piece of conductive cloth with adhesive backing or other conductive metal film with a diameter of about 8mm or other shapes with an equal area.

[0051] Step S21, contact the combined probe with the conductive cloth, see image 3 .

[0052] Step S22, the touch screen is touched;

[0053] Step S23, the oscilloscope measures the falling edge of the signal through the probe 1, and obtains the touch start time T1;

[0054] At this time, the metal touch rod in the combination probe causes a touch action, and at the same time, the conductive cloth connects the metal touch rod and oscilloscope probe 1, so that the voltage of oscilloscope probe 1 changes from 5V (or o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com