Energy-recyclable frequency converter testing system, testing method and installation method

An installation method and frequency converter technology, applied in the field of frequency converter testing, can solve problems such as energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

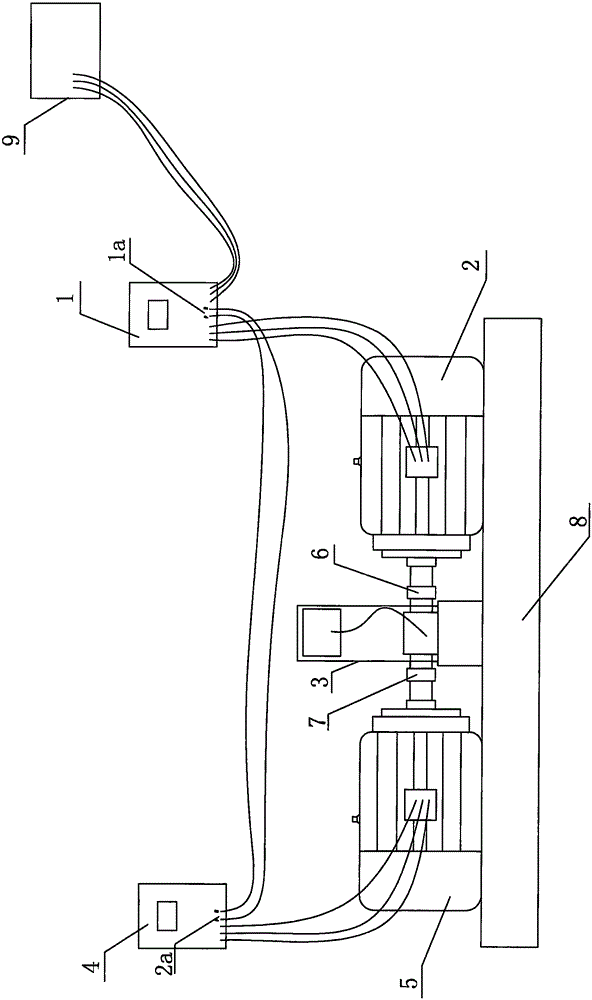

[0023] Embodiment: a kind of frequency converter test system that energy can be recovered, such as figure 1 As shown, the system includes: a front-end inverter 1 and a front-end motor 2, a torque sensor 3, a rear-end inverter 4 and a rear-end motor 5, the output end of the front-end motor 2 is connected to the front end of the torque sensor 3, and the rear end of the torque sensor 3 and The output end of the rear end motor 5 is connected. Specifically, in order to allow buffering when there is an installation error, the front end motor 2 is connected to the front end of the torque sensor 3 through the front soft connection 6, and the rear end of the torque sensor 3 is connected through the rear end. End soft connection 7 is connected together with back-end motor 5.

[0024] The bottom of front-end motor 2 and rear-end motor 5 is fixed on a base 8, and described base 8 is the base that a steel plate is made, and the weight of base 8 is greater than the summation of front-end mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com