Overrun protection and releasing system for numerical control machine tool

A CNC machine tool, overtravel technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as no application cases, large safety hazards, and guide rail detachment, etc., to achieve simple structure, low maintenance and manufacturing costs, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in further detail below in conjunction with accompanying drawing:

[0031] see Figure 1 to Figure 7 , The invention belongs to the field of design and manufacture of numerical control machine tools, and relates to a new design and improvement of overtravel protection and release methods for numerical control machine tools. The following is an example of a three-axis machine tool for illustration. The present invention can increase or decrease the number of axes according to the actual number of axes of the machine tool, and the principle of the realization method is the same.

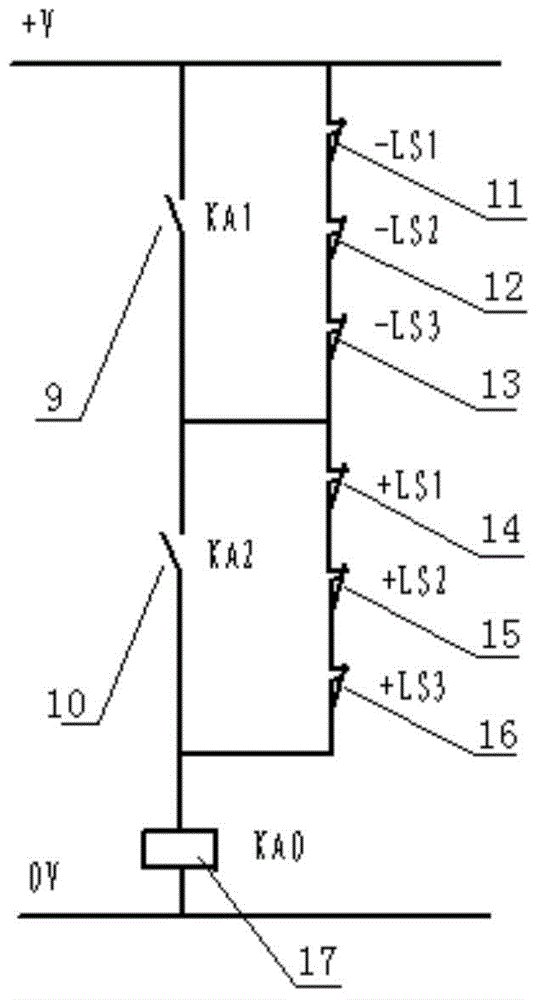

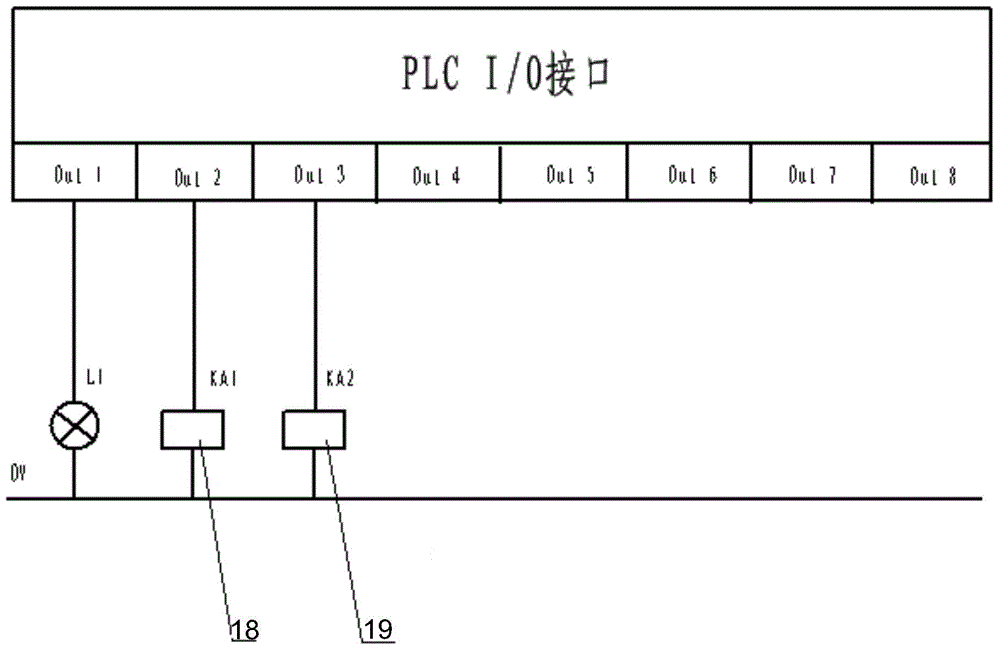

[0032] The invention consists of four parts: drive system, electric control circuit, I / O interface circuit of PLC and PLC logic.

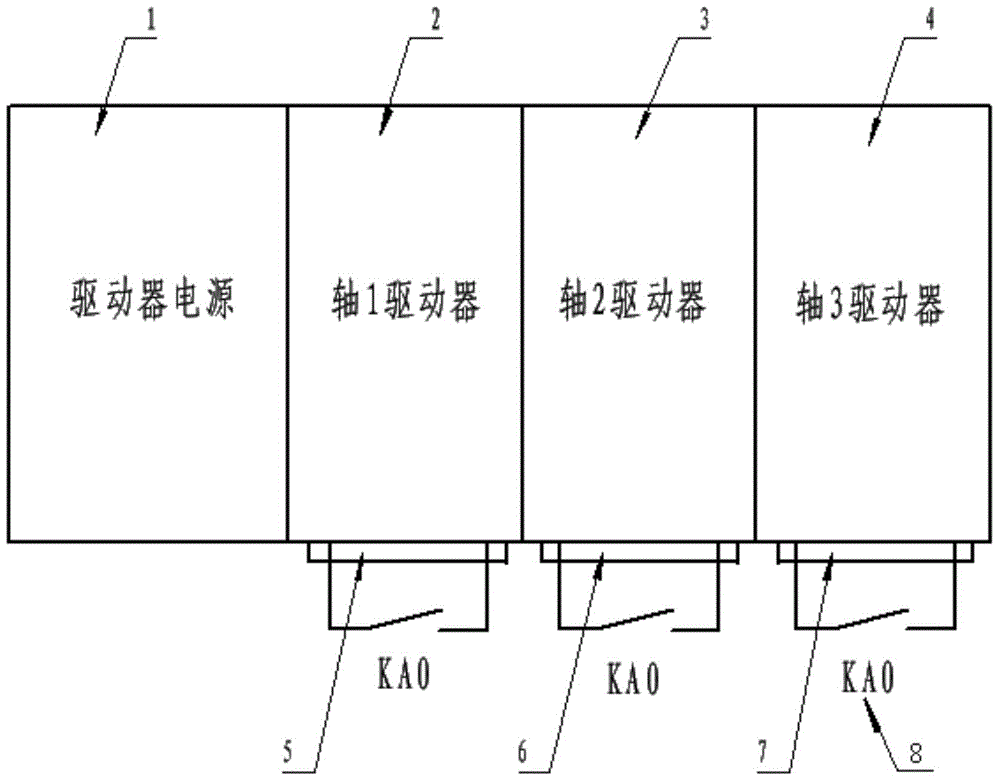

[0033] The drive system uses driver power supply 1 to provide working power for axis 1 driver 2, axis 2 driver 3, and axis 3 driver 4. Axis 1 driver 2, axis 2 driver 3, and axis 3 driver 4 drive the motors of each coordinate axis o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com