AGV and manipulator communication system and communication method thereof

A communication system and manipulator technology, applied in the field of communication systems between AGV and manipulators, can solve the problems of cumbersome wiring between loading and unloading areas and manipulators, long construction period, troublesome docking troubleshooting, etc., so as to reduce difficulty, reduce workload, and reduce wiring. effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

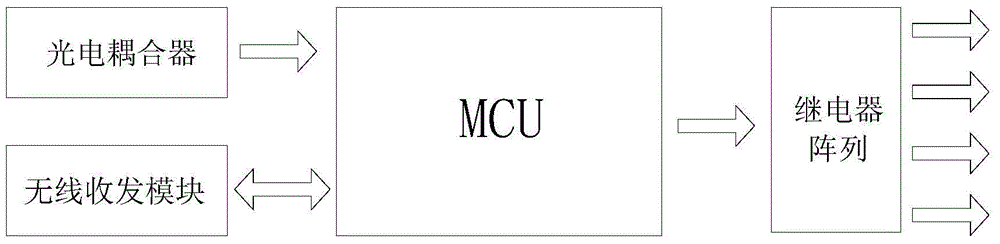

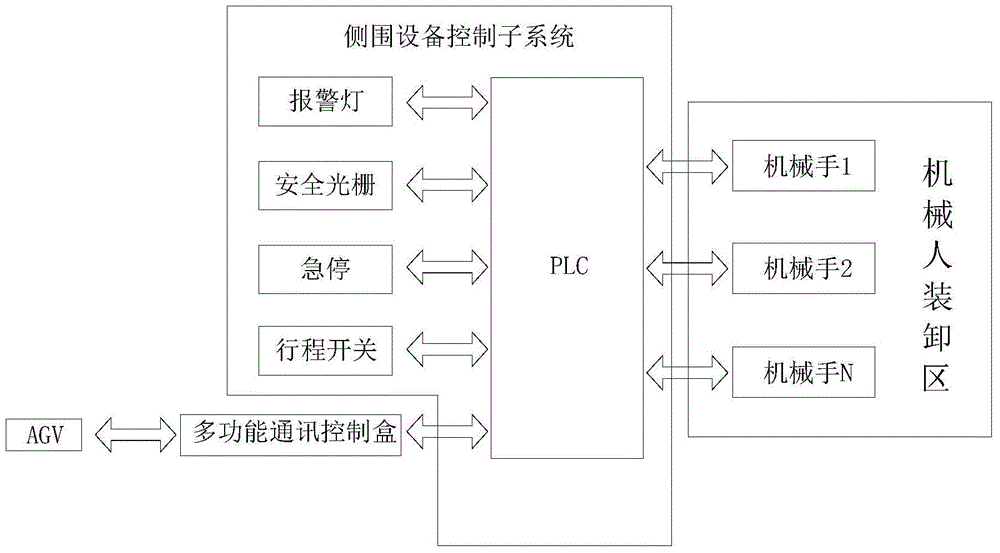

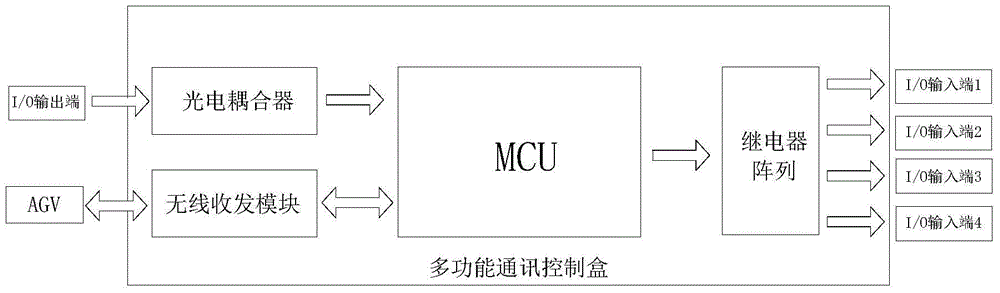

[0030] see figure 1 and figure 2 , the communication system of AGV and manipulator of the present invention, comprises AGV, manipulator, multifunctional communication control box, side enclosure equipment control subsystem, first information trigger and second information trigger; Said first information trigger and second information trigger The two information triggers are arranged sequentially along the direction that the AGV drives into the manipulator work area, specifically the first information trigger is set outside the manipulator work area, and the second information trigger is set in the manipulator work area. The AGV can sequentially read the first information trigger and the second information trigger, the multi-function communication control box communicates with the AGV wirelessly, and the multi-function communication ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com