Clamp type cable sheath grounding frame

A technology of cable sheath and grounding frame, which is applied in the field of clamp-type cable sheathing grounding frame, which can solve the problems of poor consistency of grounding resistance of the cable shielding layer, uneven length of grounding wires, and chaotic installation methods, etc., to achieve a firm installation method, Good consistency of grounding resistance and firm installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

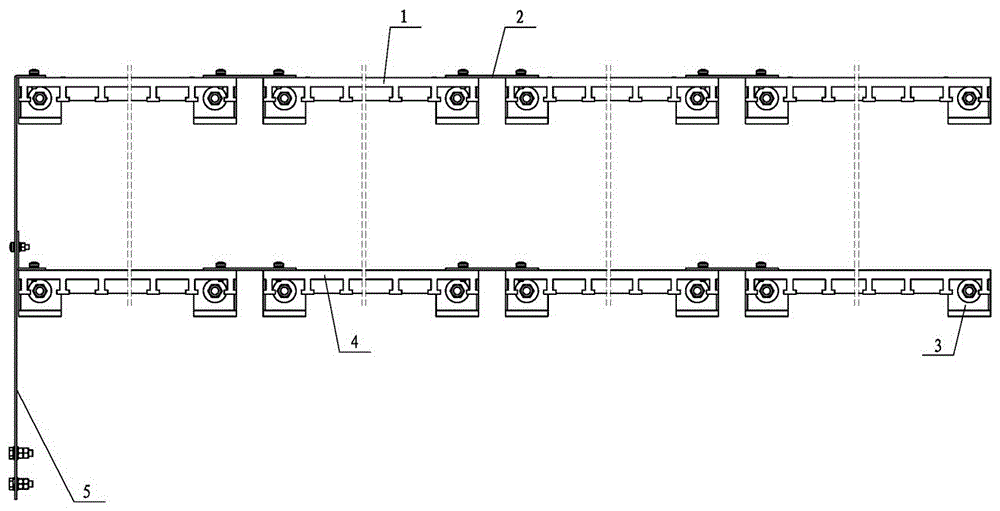

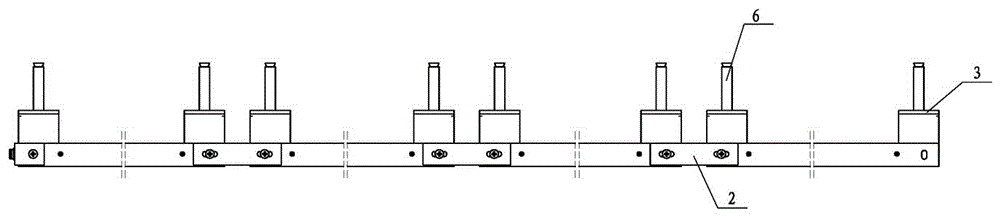

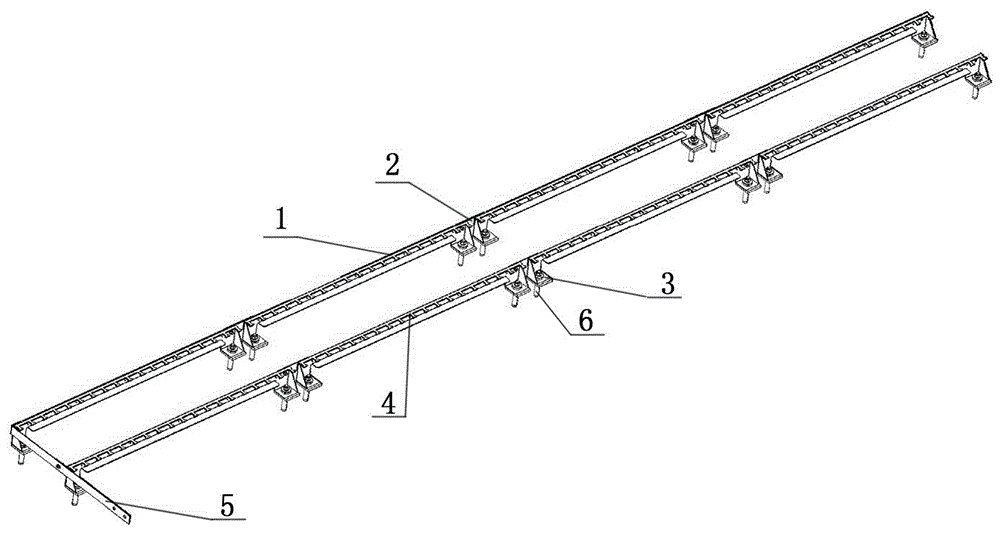

[0012] The following combination Figure 1~3 , the content of the present invention will be described in detail through specific embodiments. The clamp-type cable sheath grounding frame includes several grounding copper bar assemblies fixed on the wall, and the grounding copper bar assembly includes several grounding copper bar units I 1 and grounding copper bar units II 4 with the same structure, and the adjacent grounding copper bar Units I 1 or ground copper bar units II 4 are connected in series through bridging copper bars 2. The grounding copper bar unit I 1 or the grounding copper bar unit II 4 includes a copper bar body, a plurality of feet at equal intervals at the bottom of the copper bar body integrated with the copper bar body, and insulating sheets 3 located at both ends of the copper bar body. The same side of the grounding copper bar assembly composed of the grounding copper bar unit I 1 and the grounding copper bar assembly composed of the grounding copper bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com