Torsional vibration damper for clutch friction discs of motor vehicles

A torsional shock absorber and friction disc technology, which is applied in the direction of mechanically driven clutches, clutches, friction clutches, etc., can solve the problems of difficulty, limited angular travel, and high stiffness of coil springs, etc., and achieve the effect of simple installation and compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

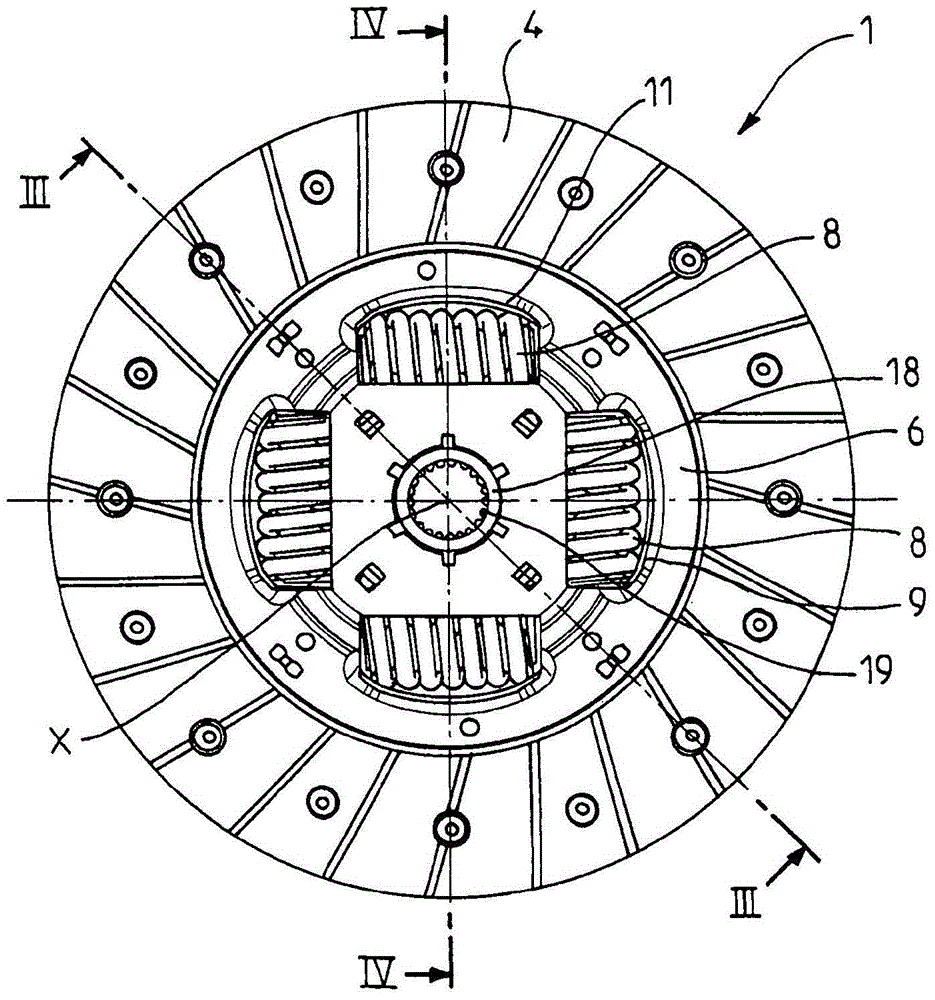

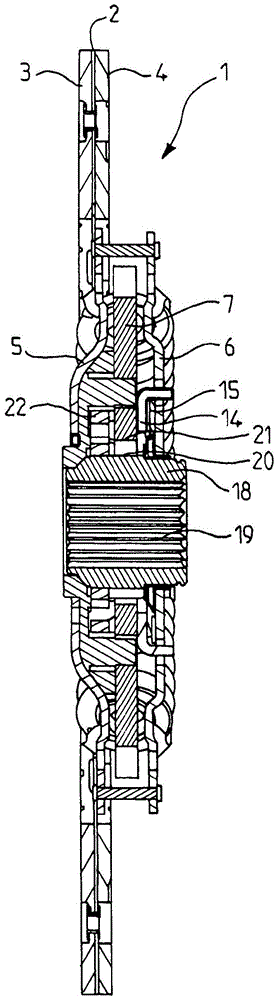

[0053] In the description and claims, the terms "outer" and "inner" and the directions "axial" and "radial" are used to designate the elements of the clutch discs according to the definitions given in the description. Generally, the direction "radial" is perpendicular to the rotation axis X of the clutch friction disc, the direction "axial" is determined from the inside to the outside away from the rotation axis, and the direction "circumferential" is orthogonal to the rotation axis X of the clutch friction disc and is orthogonal to in the radial direction.

[0054]The terms "outer" and "inner" are used to define the relative position of one element with respect to another with reference to the axis of rotation X of the clutch discs, so that an element close to the axis of rotation is called an inner element with respect to a radially peripheral outer element .

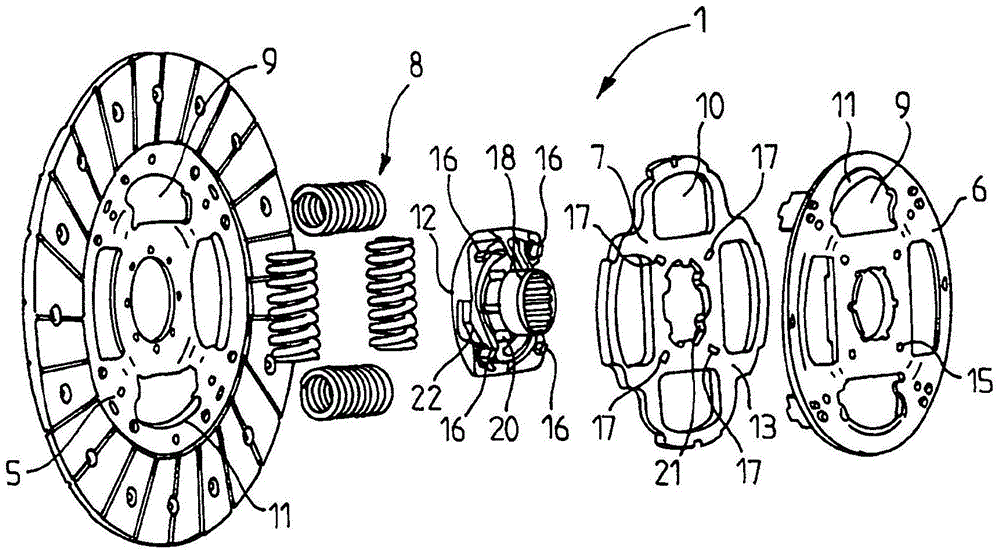

[0055] Figures 1 to 4 The shown clutch friction disc 1 is used to be installed to be fixedly connected with a dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com